Preparation method of autoclaved aerated concrete block

A technology of concrete blocks and autoclaved air filling, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of increased humidity, poor moisture insulation ability, and difficult dehumidification of air conditioning systems, etc., to achieve Enhance the firmness, enhance the waterproof and moisture-proof performance, and improve the effect of waterproof and moisture-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

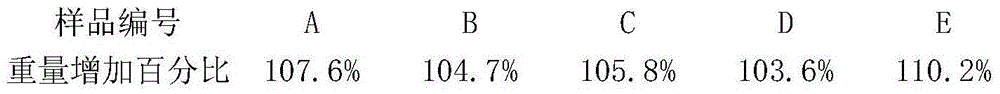

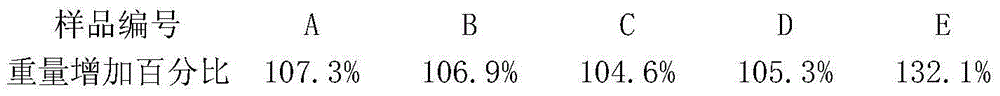

Embodiment 1

[0017] The autoclaved aerated concrete block of this embodiment includes the following components in parts by weight: 60 parts of fly ash, 10 parts of lime, 5 parts of gypsum, 5 parts of cement, 0.1 part of aluminum powder and 98% mass fraction of acrylic resin emulsion 0.1 part, the preparation steps are as follows:

[0018] (1) Add 80 parts by weight of water to grind the corresponding parts by weight except 0.1 part of acrylic resin emulsion, and make a homogeneous slurry after stirring;

[0019] (2) Let the prepared homogeneous slurry stand for 10 minutes, and pour it into the mold box after removing the supernatant;

[0020] (3) Send the mold box in step (2) into the drying room; adjust the temperature of the drying room so that the drying room maintains a pre-curing temperature of 40 degrees Celsius for 1 hour, and cut it into block embryos immediately after the pre-curing;

[0021] (4) After the cutting process in step (3), apply 0.1 part of 98% acrylic resin emulsion ...

Embodiment 2

[0024] The autoclaved aerated concrete block of this embodiment includes the following components in parts by weight: 72 parts of fly ash, 15 parts of lime, 9 parts of gypsum, 7 parts of cement, 1 part of aluminum powder and 98% mass fraction of acrylic resin emulsion 2 parts, the preparation steps are as follows:

[0025] (1) Add 100 parts by weight of water to grind the corresponding parts by weight except 3 parts of acrylic resin emulsion, and make a homogeneous slurry after stirring;

[0026] (2) Let the prepared homogeneous slurry stand for 20 minutes, and pour it into the mold box after removing the supernatant;

[0027] (3) Send the mold box in step (2) into the drying room; adjust the temperature of the drying room so that the drying room maintains a pre-curing temperature of 58 degrees Celsius for 3 hours, and cut into block embryos immediately after the pre-curing;

[0028] (4) After the cutting process in step (3), within 30 minutes of stopping the pre-cultivation,...

Embodiment 3

[0031] The autoclaved aerated concrete block of this embodiment includes the following components in parts by weight: 62 parts of fly ash, 12 parts of lime, 9 parts of gypsum, 5 parts of cement, 0.5 part of aluminum powder and 98% mass fraction of acrylic resin emulsion 1 part, the preparation steps are as follows:

[0032] (1) Add 90 parts by weight of water to grind the corresponding parts by weight except 1 part of acrylic resin emulsion, and make a homogeneous slurry after stirring;

[0033] (2) Let the prepared homogeneous slurry stand for 10 minutes, and pour it into the mold box after removing the supernatant;

[0034] (3) Send the mold box in step (2) into the drying room; adjust the temperature of the drying room so that the drying room maintains a pre-curing temperature of 50 degrees Celsius for 2 hours, and cut it into block embryos immediately after the pre-curing;

[0035] (4) After the cutting process in step (3), within 20 minutes of stopping the pre-cultivatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com