Passive building whole-process quality control system based on construction engineering dynamic management method and building

A passive building and control system technology, applied in the field of building energy conservation, can solve problems such as a single energy consumption monitoring system, and achieve the effect of improving comfort and reducing building energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

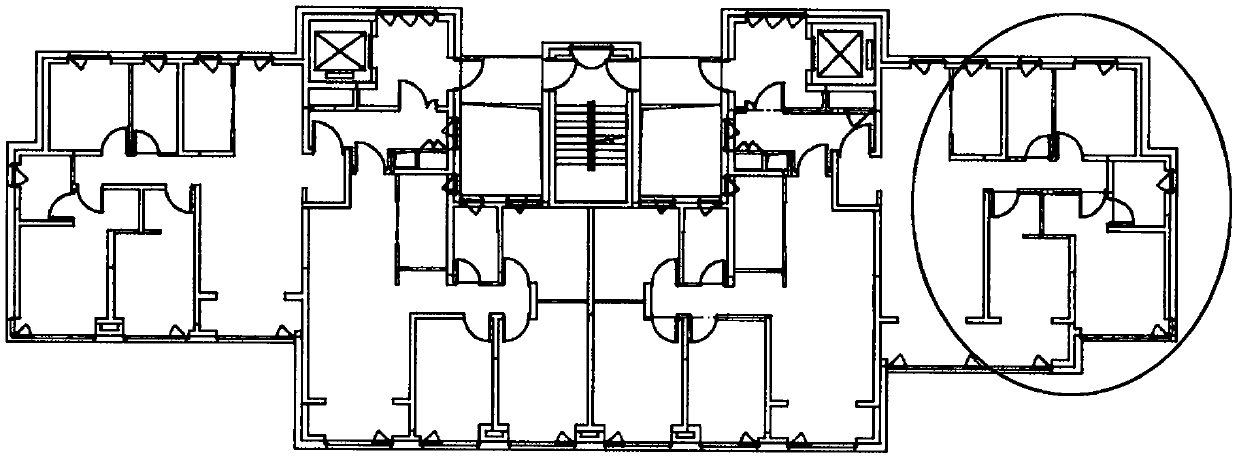

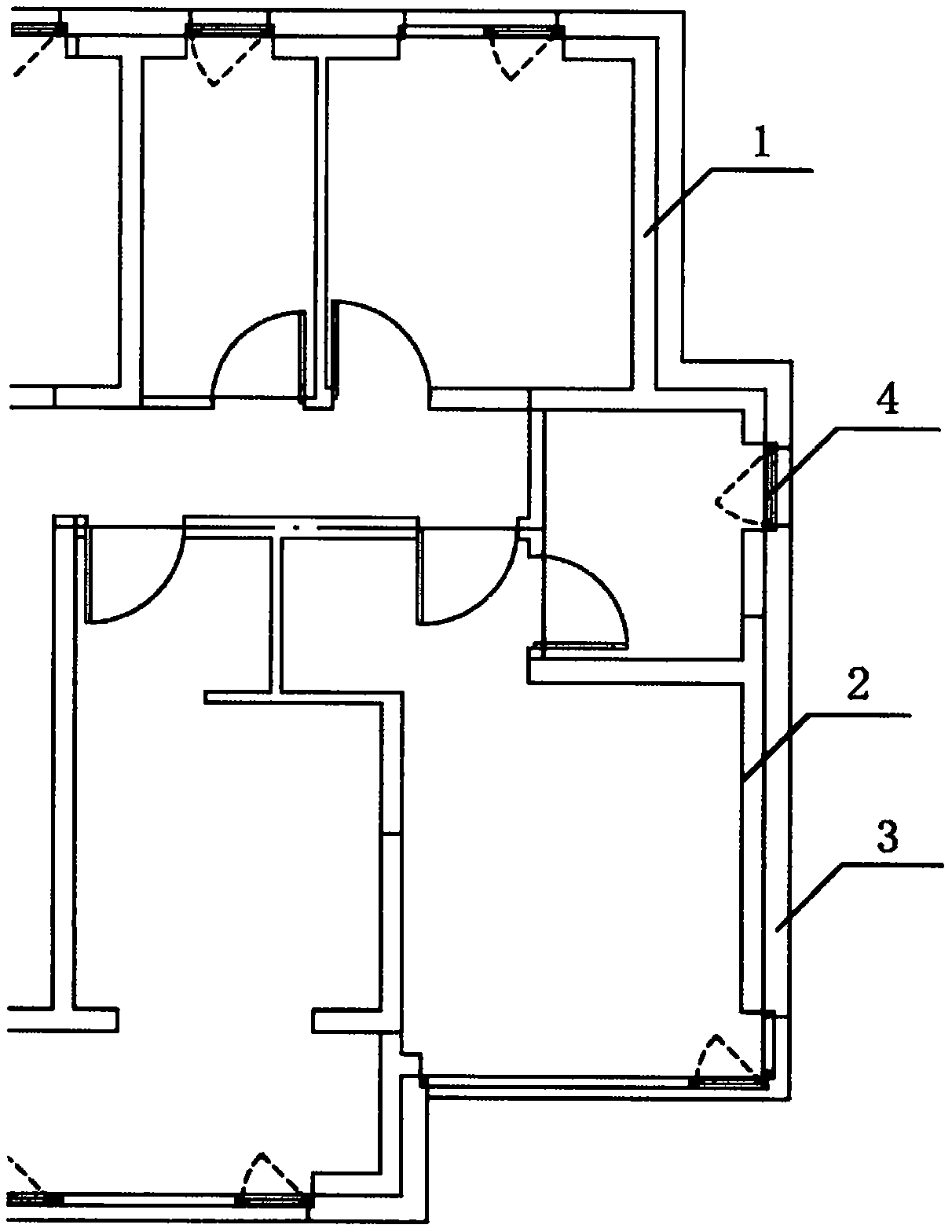

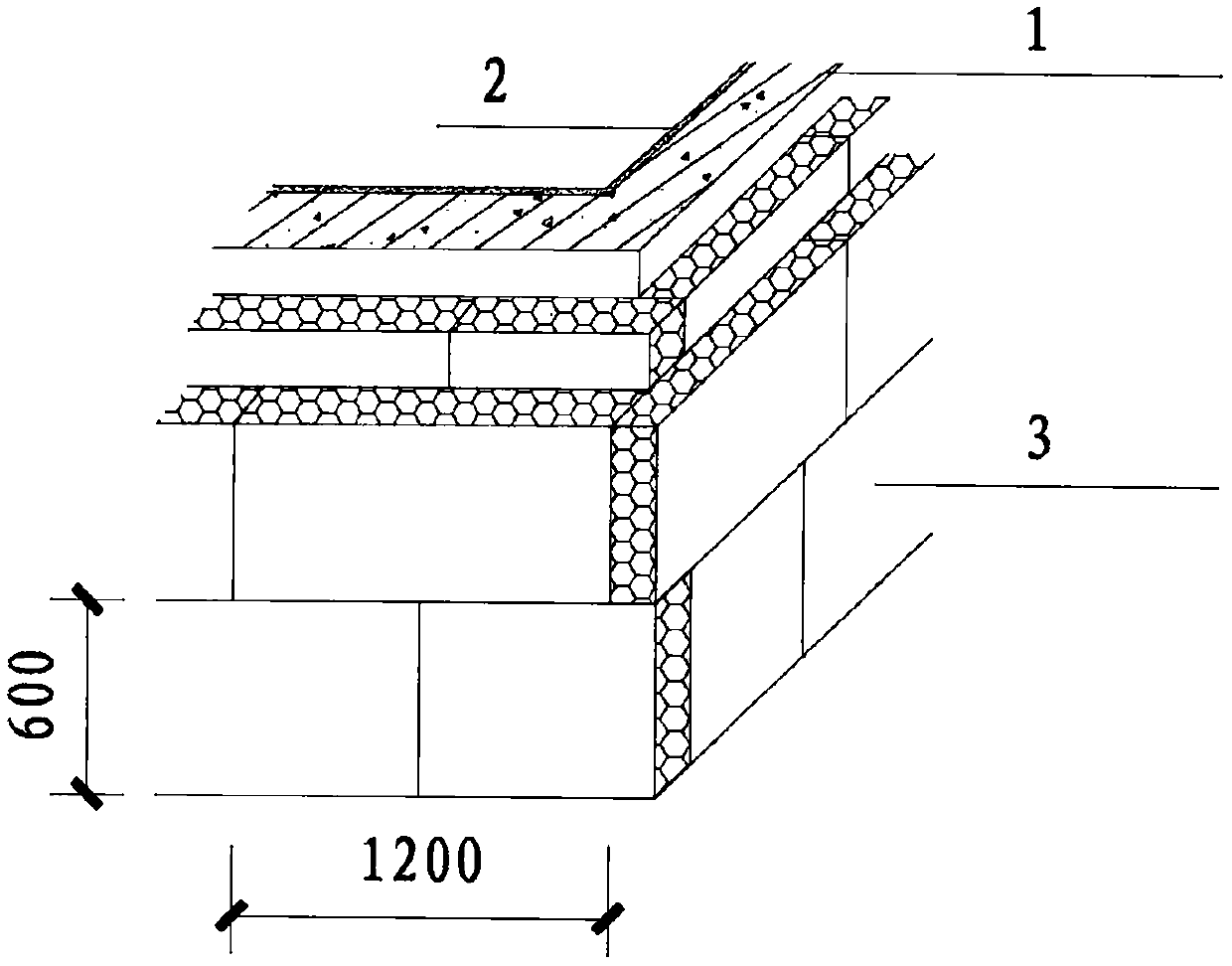

[0098] Combined with the manual Figure 1-11 , taking a passive low-energy building as an example, its basic data: 18 floors above ground, 2 floors underground, building height of 55.35m, building area of 9497.92m 2 , the structural form is a shear wall structure. The planned number of households is 72, the planned population is 3 persons / household, the shape coefficient is 0.32, and the area ratios of windows facing east, south, west and north are 0.30, 0.60, 0.30 and 0.38 respectively.

[0099] The passive low-energy building has a range of passive low-energy processing areas: 1-18 floors above the ground, the elevator room on the roof floor, and the underground part of the elevator room on the north side building.

[0100] The passive low-energy building is characterized in that: (1) ensuring superior building air tightness, avoiding unintended airflow penetration, causing unnecessary ventilation heat loss, and simultaneously avoiding indoor local temperature drops and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com