Preparation method of waterproof and flame-retardant corrugated board and waterproof and flame-retardant corrugated board

A corrugated cardboard and flame-retardant technology, which is applied in the field of corrugated cardboard, can solve the problems of restricting the use of flame-retardant corrugated cardboard, great influence on the strength of corrugated cardboard, and environmental damage, and achieve the effects of enhanced mechanical properties, convenient operation, and reduced water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

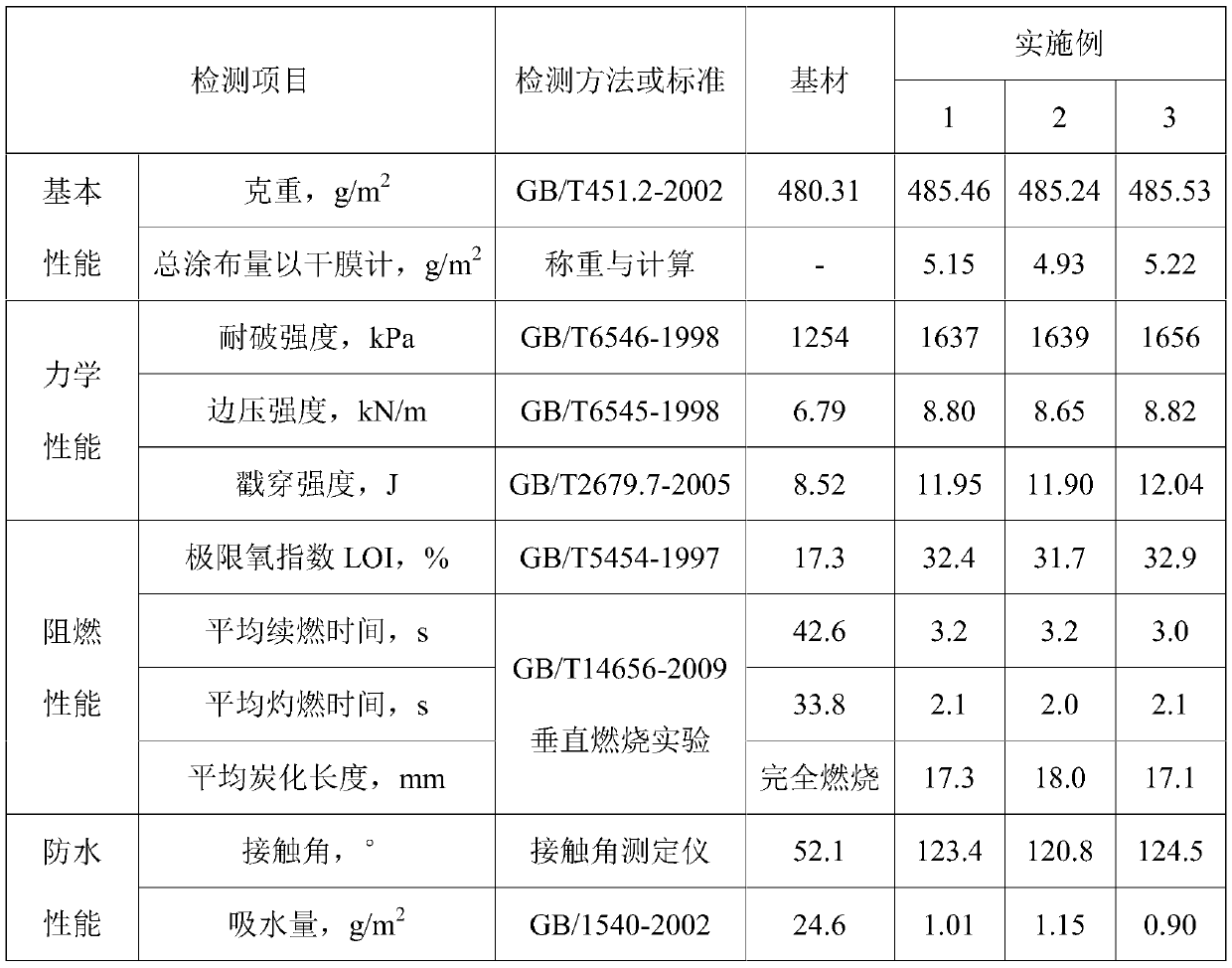

Embodiment 1

[0046] The waterproof and flame-retardant coating for corrugated cardboard of the present embodiment includes the following components in weight percent: 50% of silicone modified polyurethane aqueous dispersion, 10% of ammonium polyphosphate, 6.0% of melamine phosphate, 6.0% of pentaerythritol, iso 4.0% propanol, 3.0% isopropanol silica sol, 1.5% methyltrimethoxysilane, 0.2% nonylphenol polyoxyethylene ether, 0.5% additive, and the balance is water.

[0047] The preparation method of the waterproof flame retardant coating for corrugated cardboard of the present embodiment, comprises the following steps:

[0048] 1) Take the formula quantity of isopropanol silica sol, add 15% water of the mass of isopropanol silica sol and 1 / 3 formula quantity of methyltrimethoxysilane, stir and react at 50°C for 60min, then cool to room temperature , to obtain modified silica sol;

[0049] 2) Mix ammonium polyphosphate, melamine phosphate, and pentaerythritol with 2 / 3 of the formula amount of...

Embodiment 2

[0056] The waterproof and flame-retardant coating for corrugated cardboard of the present embodiment includes the following components in weight percent: 50% of silicone modified polyurethane water dispersion, 12% of ammonium polyphosphate, 5.0% of melamine phosphate, 5.0% of pentaerythritol, iso 4.5% propanol, 3.2% isopropanol silica sol, 1.8% methyltrimethoxysilane, 0.15% nonylphenol polyoxyethylene ether, 0.5% additive, and the balance is water.

[0057] The preparation method of the waterproof flame retardant coating for corrugated cardboard of the present embodiment, comprises the following steps:

[0058] 1) Take the isopropanol silica sol of the formula, add 12% of the mass of isopropanol silica sol and 1 / 3 of the formula of methyltrimethoxysilane, stir and react at 60°C for 50min, and then cool to room temperature to obtain Modified silica sol;

[0059] 2) Mix ammonium polyphosphate, melamine phosphate, and pentaerythritol with 2 / 3 of the formula amount of methyltrime...

Embodiment 3

[0066] The waterproof and flame-retardant coating for corrugated cardboard of the present embodiment includes the following components in weight percent: 50% of silicone modified polyurethane water dispersion, 11% of ammonium polyphosphate, 5.0% of melamine phosphate, 6.0% of pentaerythritol, iso 5.0% propanol, 3.5% isopropanol silica sol, 1.8% methyltrimethoxysilane, 0.1% nonylphenol polyoxyethylene ether, 0.5% additive, and the balance is water.

[0067] The preparation method of the waterproof flame retardant coating for corrugated cardboard of the present embodiment, comprises the following steps:

[0068] 1) Take the isopropanol silica sol of the formulation amount, add 10% of the mass of the isopropanol silica sol and 1 / 3 of the formulation amount of methyltrimethoxysilane, stir and react at 55°C for 55min, and then cool to room temperature to obtain Modified silica sol;

[0069]2) Mix ammonium polyphosphate, melamine phosphate, and pentaerythritol with 2 / 3 of the formu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Edge compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com