A kind of shale polyamine film-forming inhibitor and preparation method thereof

A mud shale and inhibitor technology, applied in the field of mud shale polyamine film-forming inhibitor and its preparation, can solve the problems of high cost and environmental protection, restrictions, etc., and achieve low freezing point, moderate product price and strong adsorption and the inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 shale polyamine film-forming inhibitor

[0030] By optimizing the reactants, reactant ratio and synthesis conditions of a shale polyamine film-forming inhibitor, the optimal plan for the synthesis of the inhibitor is obtained, and the specific steps are as follows:

[0031] (1) The reaction kettle is cleaned and dried, and 38% of amine compounds (polyethylene polyamines) are added;

[0032] (2) Slowly add 62% of epoxy compound (epichlorohydrin), add in three times, and control the temperature of the reactor during the addition process to be no more than 80°C;

[0033] (3) adding a molecular weight regulator (low-molecular linear 1,2-ethyleneamine), the amount added is 0.4% of the total mass of the reactants (polyethylene polyamine and epichlorohydrin);

[0034] (4) Introduce nitrogen protection, heat up to 85 ° C, react for 3 hours, and monitor the change of pH value during the reaction;

[0035] (5) When the pH value reaches 8.5, conti...

Embodiment 2

[0038] The usage method of embodiment 2 mud shale polyamine film-forming inhibitor

[0039] (1) In the drilling process, when encountering muddy shale, add 0.5%~1.0% muddy shale polyamine film-forming inhibitor of the present invention in mud, should be slow when adding, and mix evenly;

[0040] (2) Pretreatment of oil and gas production wells, before putting into production, inject 1.0% to 2.0% of the mud shale polyamine film-forming inhibitor of the present invention to sandstone oil layers with relatively high clay content, and the treatment radius is 2.0m to 5.0m , the purpose of prolonging the production cycle of oil and gas wells;

[0041] (3) In the water injection wells of oil and gas reservoirs with relatively high clay content or relatively high water injection pressure, intermittently inject 0.1% to 0.5% of the mud shale polyamine film-forming inhibitor of the present invention to achieve increased injection and reduced water injection the effect of pressure;

[0...

Embodiment 3

[0043] Embodiment 3 Mud shale anti-expansion performance evaluation test of shale polyamine film-forming inhibitor

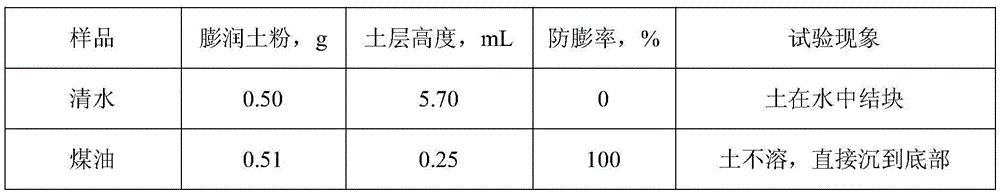

[0044] (1) Centrifuge tube method to evaluate the anti-swelling effect of shale polyamine film-forming inhibitor (prepared in Example 1) at normal temperature and pressure. See Table 1.

[0045] Table 1 Anti-swelling effect of shale polyamine film-forming inhibitors at normal temperature and pressure

[0046]

[0047]

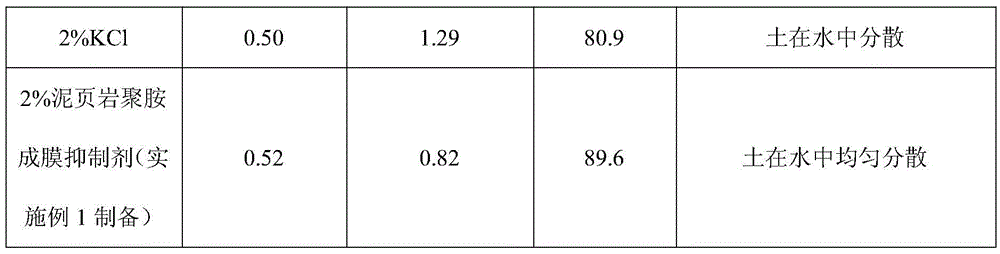

[0048] (2) The comparison results of the anti-expansion test of drilling filtrate measured by high-temperature and high-pressure dilatometer are shown in Table 2.

[0049] Table 2 Comparison of shale expansion performance test results

[0050]

[0051] The results show that at room temperature and high temperature, the anti-swelling effect of the shale polyamine film-forming inhibitor (prepared in Example 1) system is significantly better than that of KCl, and it can more effectively inhibit the hydration expansion of formations and cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com