Gasoline fabric-scraping adhesive slurry and preparation method thereof

A technology of glue and scraping cloth, which is applied in the field of materials for making scraping glue, can solve the problems of short life, difficult reprocessing, and large toxic and side effects, and achieve the effects of improving aesthetics, increasing initial viscosity, and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

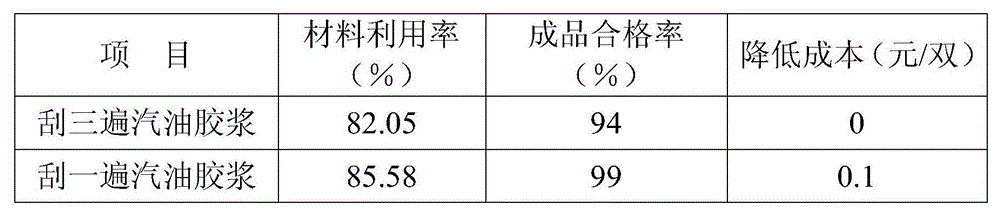

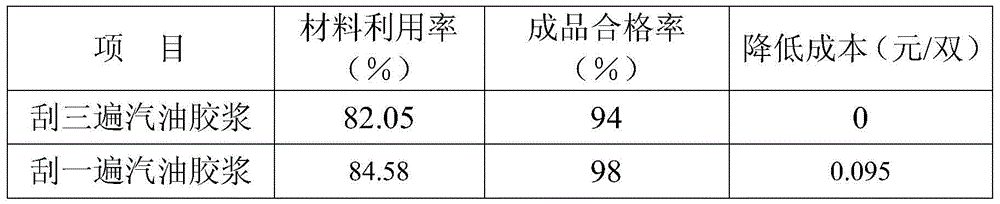

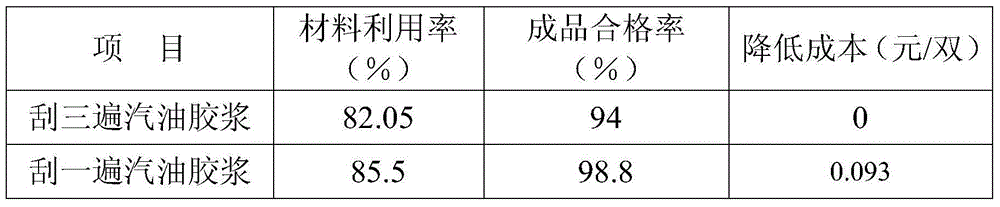

Examples

preparation example Construction

[0024] A kind of preparation method of gasoline scraping cloth mortar of embodiment, comprises the following steps:

[0025] a. Gum breaking: make 1# cigarette rubber breaking gum into film by weight;

[0026] b. Masticating: Put 1# smoked rubber film into the open mill with a roller distance of 0.5mm or less and a roller temperature of 40°C to 50°C using the thin-pass plasticating method, and then discharge and cool after plasticizing thin-pass. Put the cooled rubber material into the open mill with a roller distance of 5mm-8mm and wrap the rollers for mastication. After the rubber material is smooth and flat, put the test sample and make the rubber material into a film, and leave it for more than 8 hours to obtain the plasticized rubber. ,stand-by;

[0027] c. Ingredients: mix accelerant, active zinc oxide, stearic acid, anti-aging agent by weight to make mixture I; mix rosin, antibacterial agent and colorant by weight to make mixture II; Prepare material III with light ca...

Embodiment 1

[0034] The gasoline squeegee glue of the present embodiment, the raw material comprises the following components by weight: 100 parts of 1# cigarette rubber, 0.8 part of sulfur, 1.6 parts of active zinc oxide, 0.9 part of stearic acid, 1.1 part of accelerator M, 0.2 parts of agent D, 1.25 parts of anti-aging agent sp-c, 240 parts of light calcium carbonate, 19 parts of machine oil, 5 parts of rosin, 35 parts of antibacterial agent, 0.8 part of colorant, 4 parts of terpene resin, and 140 parts of clay.

[0035] A kind of preparation method of gasoline scraping cloth mortar of the present embodiment, comprises the following steps:

[0036] a. Gum breaking: make 1# cigarette rubber breaking gum into film by weight;

[0037] b. Masticating: Put 1# smoked rubber film into the open mill with a roller distance of 0.5mm or less and a roller temperature of 40°C to 50°C using the thin-pass plasticating method, and then discharge and cool after plasticizing thin-pass. Put the cooled rubbe...

Embodiment 3

[0055] The gasoline squeegee glue of the present embodiment, the raw material comprises the following components by weight: 100 parts of 1# cigarette rubber, 0.9 part of sulfur, 1.5 parts of active zinc oxide, 1.0 part of stearic acid, 0.9 part of accelerator M0, accelerator 0.4 parts of agent D, 1.45 parts of anti-aging agent sp-c, 280 parts of light calcium carbonate, 25 parts of machine oil, 6 parts of rosin, 36.5 parts of antibacterial agent, 0.9 parts of colorant, 6.5 parts of terpene resin, and 160 parts of clay.

[0056] A kind of preparation method of gasoline scraping cloth mortar of the present embodiment, comprises the following steps:

[0057] a. Gum breaking: make 1# cigarette rubber breaking gum into film by weight;

[0058] b. Masticating: Put 1# smoked rubber film into the open mill with a roller distance of 0.5mm or less and a roller temperature of 40°C to 50°C using the thin-pass plasticating method, and then discharge and cool after plasticizing thin-pass. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com