Modified asphalt and preparation method thereof

A technology of modified asphalt and matrix asphalt, which is applied in building components, building insulation materials, buildings, etc., can solve problems such as environmental pollution and waste of resources, and achieve low price, reduce road rutting, and good technical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

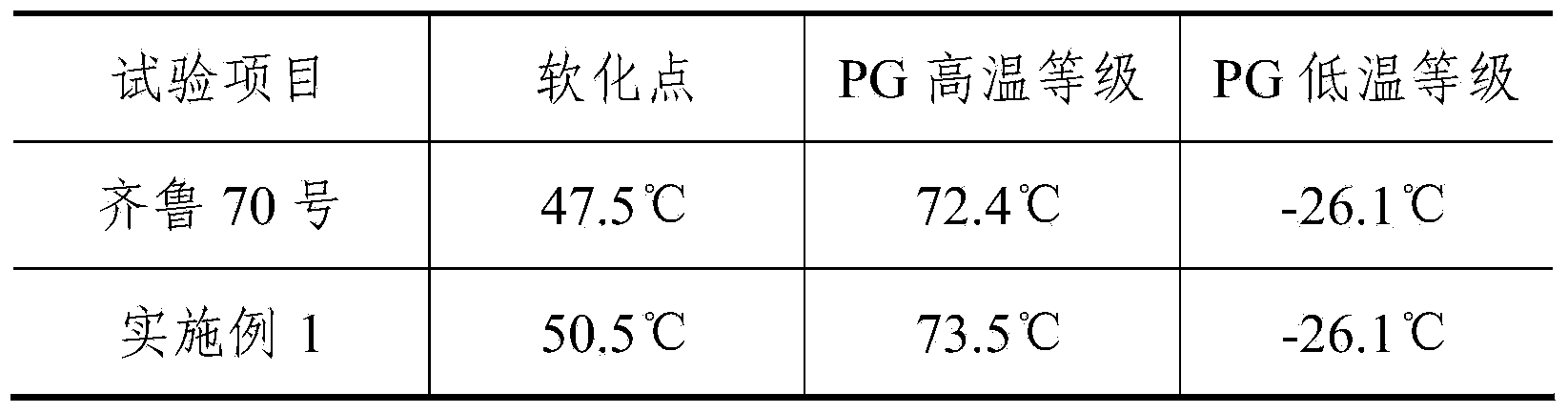

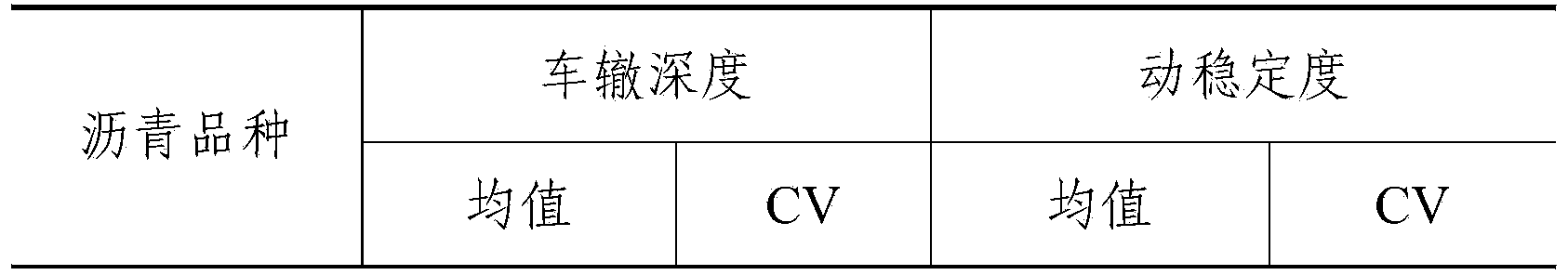

Embodiment 1

[0032] A kind of modified asphalt provided by the present embodiment, Qilu No. 70 matrix asphalt and Ricoh brand printer waste toner, the added quality of this toner accounts for 2% of the modified asphalt, aluminate coupling agent and stearic acid synergist The added mass accounts for 0.5% and 0.125% of the modified asphalt respectively. The preparation method of this modified asphalt comprises the following steps:

[0033] Put Qilu No. 70 base asphalt in an oven at 160°C to preheat until softened, weigh the carbon powder in proportion, preheat it to 100°C, add the preheated carbon powder to Qilu No. 70 base asphalt while stirring, and then put the Put the container with asphalt into a constant temperature heating mantle for high-speed shearing. The shearing temperature is 160°C, the shearing rate is 3800r / min, and the shearing time is 25min. Then weigh the aluminate coupling agent in proportion and add it to In asphalt, the shear temperature is 160°C, the shear rate is 3800...

Embodiment 2

[0042]A kind of modified asphalt provided by the present embodiment, Qilu No. 70 matrix asphalt and Ricoh brand printer waste carbon powder and aluminate coupling agent and stearic acid synergist, the added quality of this carbon powder accounts for 8% of modified asphalt , the addition of aluminate coupling agent and stearic acid synergist accounts for 1.5% and 0.75% of the modified asphalt respectively. The preparation method of this modified asphalt comprises the following steps:

[0043] Put Qilu No. 70 base asphalt into an oven at 160°C to preheat until softened, weigh the carbon powder in proportion, preheat it to 105°C, add the weighed carbon powder into Qilu No. 70 base asphalt while stirring, and then put the The container with asphalt is put into a constant temperature heating mantle for high-speed shearing, the shearing temperature is 163°C, the shearing rate is 4000r / min, and the shearing time is 30mins, then the aluminate coupling agent is weighed in proportion an...

Embodiment 3

[0051] A kind of modified asphalt provided by the present embodiment, Qilu No. 70 base asphalt and brother brand printer waste toner, aluminate coupling agent and stearic acid synergist, the added quality of this carbon powder accounts for 12% of the modified asphalt , the added mass of aluminate coupling agent and stearic acid synergist accounted for 2% and 1.5% of the modified asphalt, respectively. The preparation method of this modified asphalt comprises the following steps:

[0052] Put Qilu No. 70 base asphalt in an oven at 160°C to preheat until softened, weigh the carbon powder in proportion, preheat it to 110°C, add the weighed carbon powder to Qilu No. 70 base asphalt while stirring, and then put the Put the asphalt container into a constant temperature heating mantle for high-speed shearing. The shearing temperature is 165°C, the shearing rate is 4500r / min, and the shearing time is 35min. Then weigh the aluminate coupling agent in proportion and add it to In asphal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com