Organic soil for oil base drilling fluids with high yield value and preparation method thereof

An oil-based drilling fluid with high yield technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of low yield value of drilling fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

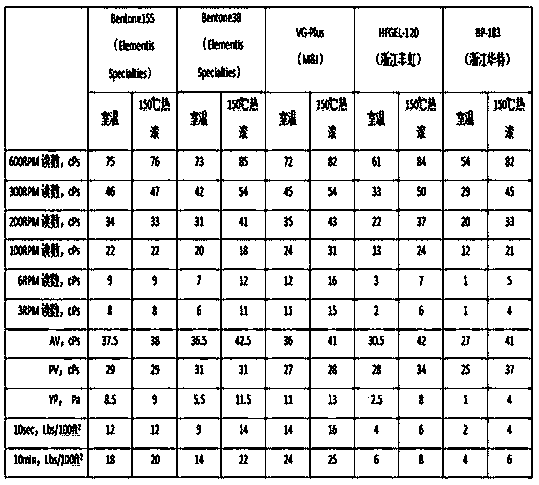

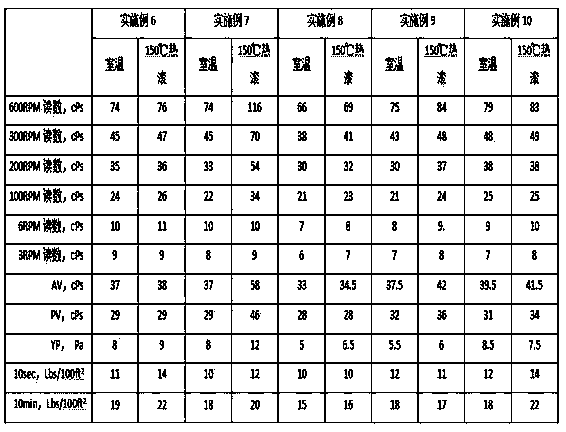

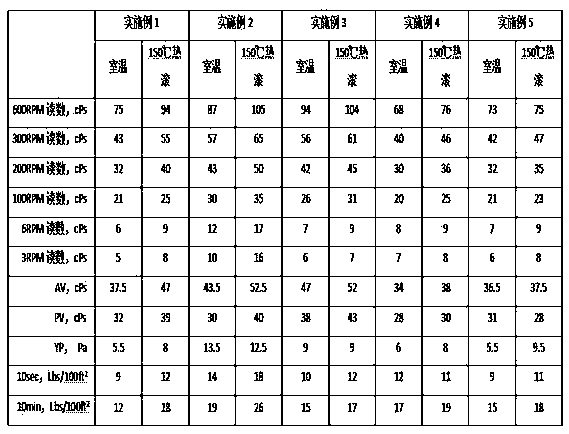

Examples

Embodiment 1

[0028] (1) Disperse Anji calcium-based bentonite raw ore powder in fresh water or deionized water for beating;

[0029] (2) Add 3.5% NaF of soil amount and stir for 1~2 hours. Remove impurities by a horizontal centrifuge. The separated suspension is passed through a disc centrifuge to further remove impurities to obtain a sodium-based montmorillonite suspension;

[0030] (3) Heat the sodium-based montmorillonite suspension to 80°C while stirring, keep it warm for 1 hour, adjust the pH of the suspension to pH=3.5 with sulfuric acid, and continue stirring for 1 hour;

[0031] (4) Add sodium-based montmorillonite cation exchange capacity ( CEC ) 1.0 times of octadecyl dimethyl benzyl ammonium chloride, continue to stir and react for 1 hour;

[0032] (5) At the same time, add sodium-based montmorillonite cation exchange capacity ( CEC ) of 0.1 times bis(tallow ethyl amide) polyethoxymethyl ammonium methyl sulfate and 0.1 times CEC Stearic acid, continue stirring reaction 0.5~...

Embodiment 2

[0035] The alkyl quaternary ammonium salt cationic surfactant in step (4) in Example 1 is replaced by octadecyltrimethylammonium chloride, and the addition is 0.9 times CEC . Other steps are the same as in Example 1.

Embodiment 3

[0037] The quaternary ammonium salt cationic surfactant with strong polar groups in step (5) in Example 1 is replaced by octadecyl dihydroxyethyl ammonium chloride, and the addition is adjusted to 0.15 times CEC . Other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com