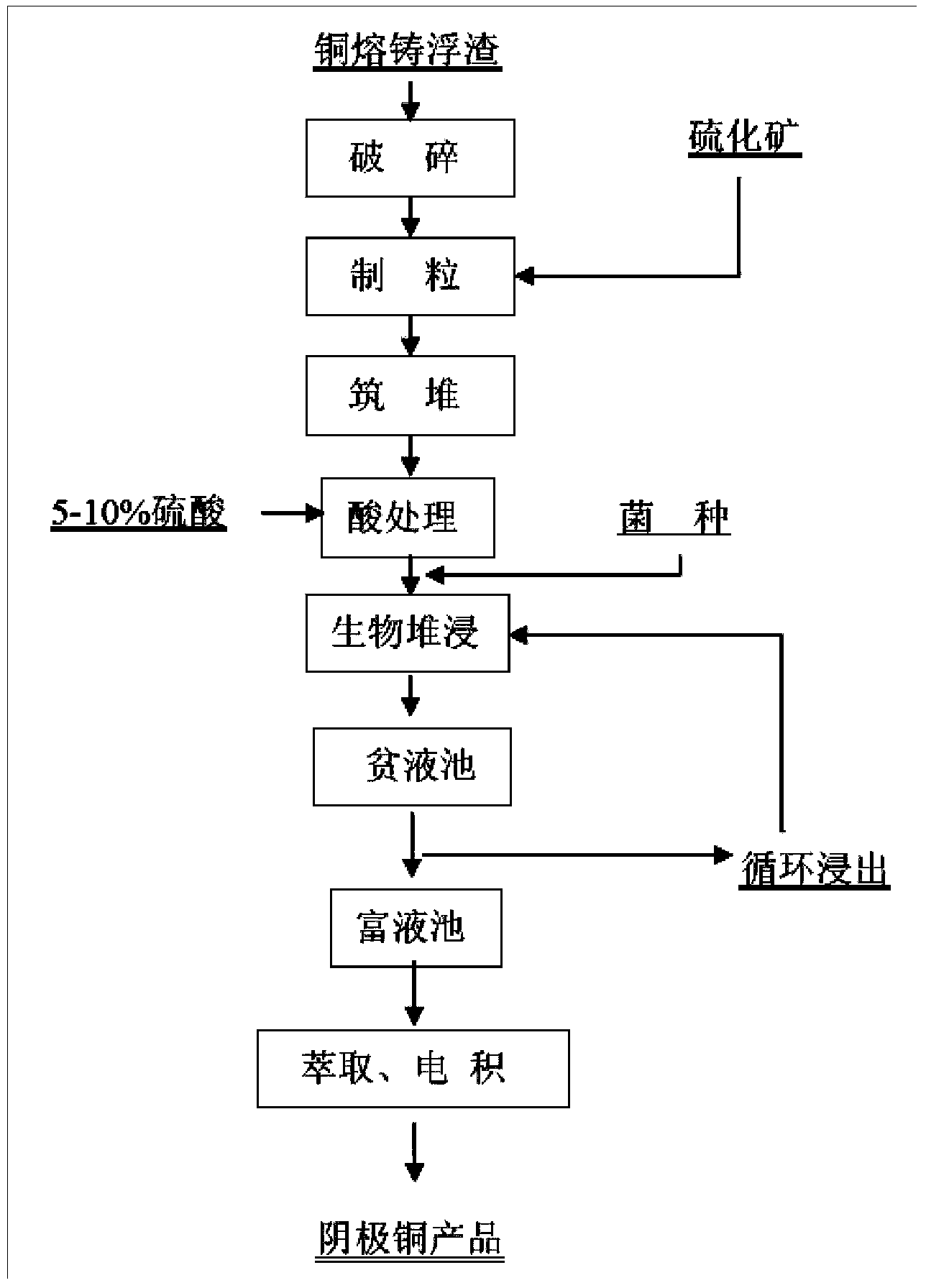

Copper recycling process of copper casting scum by utilizing biological dump leaching

A technology for biostack and copper recovery, applied in the chemical industry, can solve the problems of large extraction impact, uneconomical copper extraction process, and oxidative deterioration of extractant, and achieves the effects of simple equipment, easy implementation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Naturally cooled copper casting dross from a copper strip processing enterprise, copper mainly exists in the form of simple copper, and its chemical composition is shown in Table 1.

[0025] Table 1 Analysis results of main elements* / %

[0026]

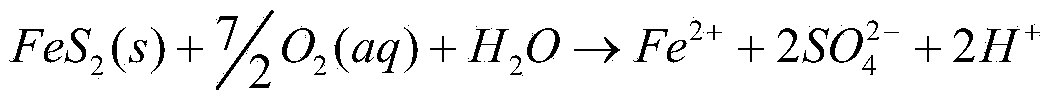

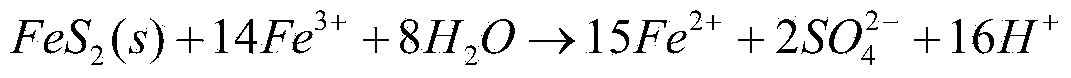

[0027] Take the copper casting scum described in Table 1, crush it to -20mm (below 20mm) through the crushing system, add pyrite with a particle size of -10mm (below 10mm) after crushing, pyrite and copper casting scum The weight ratio is 1:1, and it is granulated by a cylinder granulator, and transported to the storage yard by a dump truck or a belt for piling. Utilize concentration to be 10% sulfuric acid to rinse ore heap, make ore heap pH value be adjusted to 1.5. Microorganisms are inserted into the ore heap, and iron is oxidized to ferric iron by the action of microorganisms, and copper is oxidized and leached by ferric iron and bioleaching process to produce acid. During the heap leaching process, the heap height is...

Embodiment 2

[0029] Naturally cooled copper casting dross from a copper foil processing enterprise, copper mainly exists in the form of simple copper, and its chemical composition is shown in Table 2.

[0030] Table 2 Analysis results of main elements* / %

[0031]

[0032] Take the copper melting and casting scum described in Table 2, and crush it to -20mm through a crushing system, add pyrite with a particle size of -10mm after crushing, the weight ratio of pyrite and copper melting and casting scum is 6:1, and pass through a circle The pellets are granulated by the drum granulator and transported by dump truck or belt to the storage yard for stacking. The ore heap is rinsed with sulfuric acid with a concentration of 5%, so that the pH value of the ore heap is adjusted to 2.5. Microorganisms are inserted into the ore heap, and iron is oxidized to ferric iron by the action of microorganisms, and copper is oxidized and leached by ferric iron and bioleaching process to produce acid. Duri...

Embodiment 3

[0034] Naturally cooled copper casting dross from a copper strip processing enterprise, copper mainly exists in the form of elemental copper, and its chemical composition is shown in Table 3.

[0035] Table 3 Analysis results of main elements* / %

[0036]

[0037] Get the copper melting and casting scum described in Table 3, it is broken to-20mm by crushing system, add the mixed ore of pyrite and copper sulfide (CuS) that particle size is -10mm after breaking, the content of pyrite in the mixed ore is 30%, CuS content is 6%. The weight ratio of mixed ore to copper casting scum is 5:1, which is granulated by a cylinder granulator and transported to the storage yard by a belt for piling. Utilize concentration to be 8% sulfuric acid leaching ore heap, make ore heap pH value be adjusted to 2.5. Microorganisms are inserted into the ore heap, and iron is oxidized to ferric iron by the action of microorganisms, and copper is oxidized and leached by ferric iron and bioleaching pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com