Bed course replacing and filling and carbonization reinforcing method of soft soil foundation

A soft soil foundation and cushion technology, applied in soil protection, basic structure engineering, construction, etc., can solve problems such as shortening the cycle, uneven settlement, increasing soil strength, etc., and achieve the goal of increasing strength and reducing gas Dissipation, avoiding the effect of uneven settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

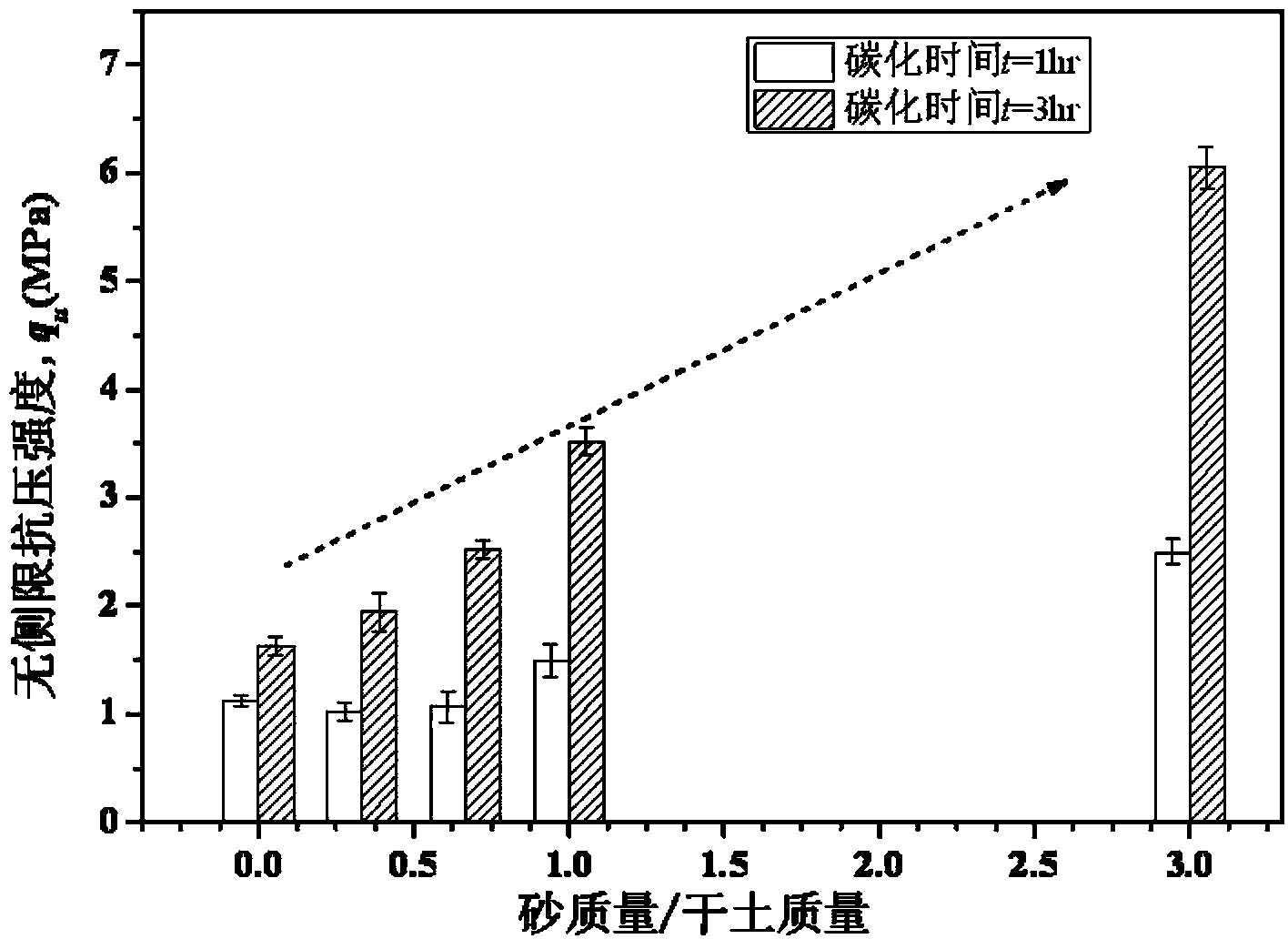

Embodiment 1

[0028] The inventive method comprises the following steps:

[0029] (1) earthwork excavation: according to the geological prospecting results, determine the treatment depth and scope of the soft soil foundation 6, excavate and replace the pit groove 7 with an excavator, the excavation depth is 2.5m, and replace and fill the pit groove 7 Clean up the floating soil;

[0030] (2) Preparation of replacement materials

[0031] Mix the following materials according to the weight ratio, and stir evenly with a mixer to prepare the filling material:

[0032] Silt: fine sand: gravel: light magnesium oxide: water = 100: (10-300): 5: 15: 20; the particle size of fine sand is less than 2mm;

[0033] (3) Pit bottom disposal and initial pressure

[0034] Sprinkle water to moisten the surface layer of the bottom of the pit for refilling the pit 7, then spray light magnesium oxide powder, and compact it with a rammer;

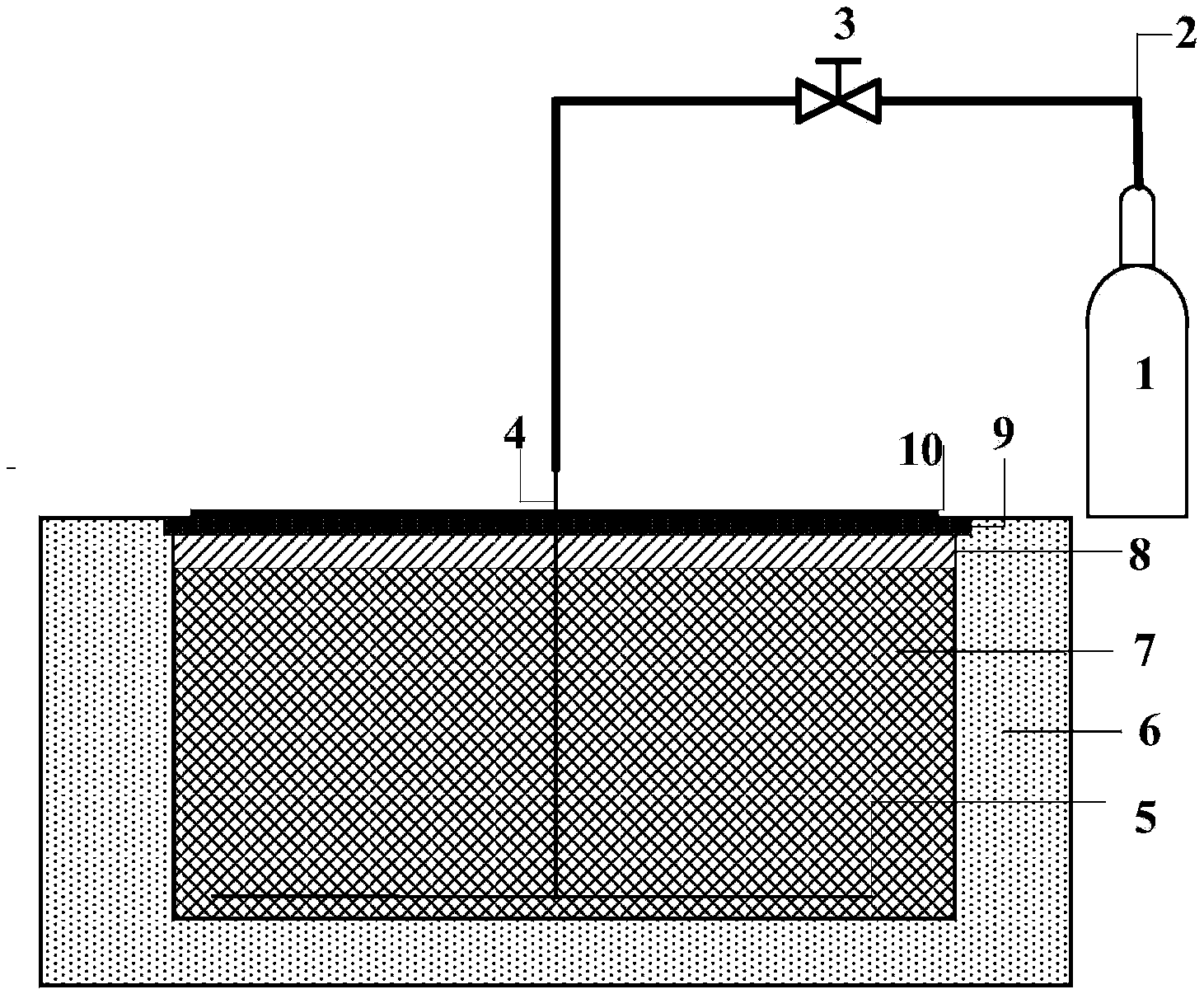

[0035] (4) Lay the ventilation pipe network: the ventilation pipe netw...

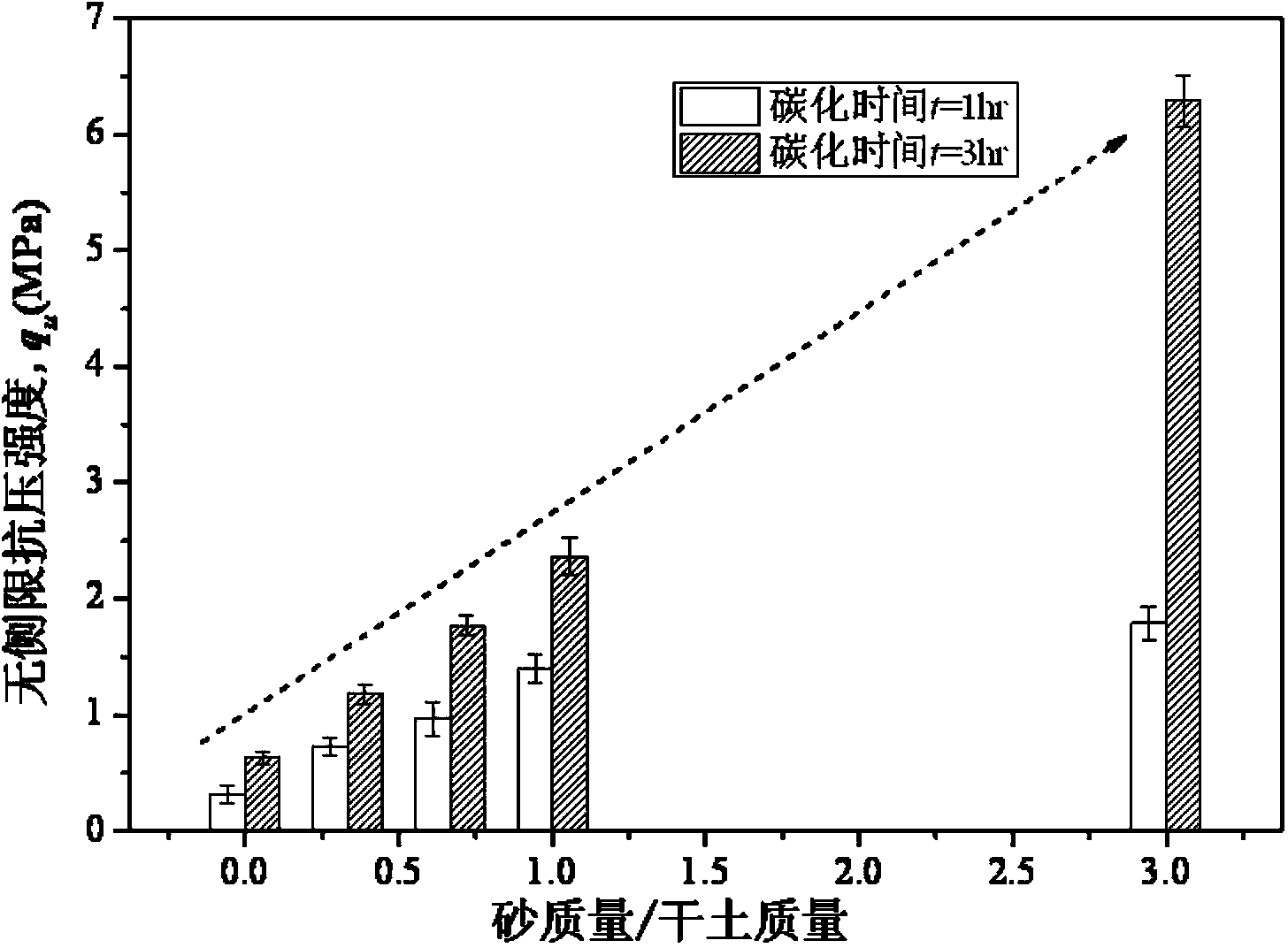

Embodiment 2

[0042] The inventive method comprises the following steps:

[0043] (1) earthwork excavation: according to the geological prospecting results, determine the treatment depth and scope of the soft soil foundation 6, excavate and replace the pit groove 7 with an excavator, the excavation depth is 2.5m, and replace and fill the pit groove 7 Clean up the floating soil;

[0044] (2) Preparation of replacement materials

[0045] Mix the following materials according to the weight ratio, and stir evenly with a mixer to prepare the filling material:

[0046] Soft soil: fine sand: gravel: light magnesium oxide: water = 100: (10-300): (5-15): (15-20): 15; the particle size of fine sand is less than 2mm;

[0047] (3) Pit bottom disposal and initial pressure

[0048] Sprinkle water to moisten the surface layer of the pit bottom of the replacement pit 7, then spray light magnesium oxide powder, and compact with a rammer;

[0049] (4) Lay the ventilation pipe network: the ventilation pip...

Embodiment 3

[0056] The inventive method comprises the following steps:

[0057] (1) earthwork excavation: according to the geological prospecting results, determine the treatment depth and scope of the soft soil foundation 6, excavate and replace the pit groove 7 with an excavator, the excavation depth is 2.5m, and replace and fill the pit groove 7 Clean up the floating soil;

[0058] (2) Preparation of replacement materials

[0059] Mix the following materials according to the weight ratio, and stir evenly with a mixer to prepare the filling material:

[0060] Silt: fly ash: gravel: light magnesium oxide powder: water = 100: (20-200): (15-30): (15-30): 30; the particle size of fly ash is less than 2mm;

[0061] (3) Pit bottom disposal and initial pressure

[0062] Sprinkle water on the surface layer of the bottom of the pit for refilling pit 7, then spray light magnesium oxide powder, and compact with a road roller;

[0063] (4) Lay the ventilation pipe network: the ventilation pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com