Ambroxol hydrochloride atomization inhalant, and preparation method and application thereof

A technology of ambroxol hydrochloride and aerosol inhaler, which is applied in directions such as aerosol delivery, pharmaceutical formulations, respiratory diseases, etc., can solve problems such as unsafe use, instability of ambroxol hydrochloride aerosol inhaler, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

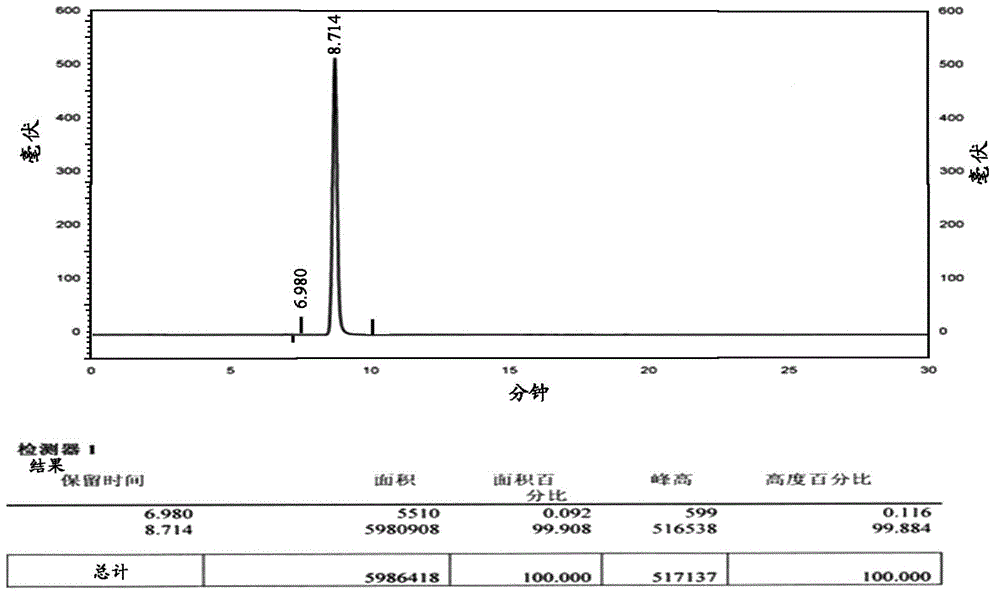

Embodiment 1

[0052] Example 1 1000 pieces

[0053] Prescription: Specification 2ml: 15mg

[0054] Ambroxol Hydrochloride 15.0g

[0055] Citric acid 2.0g

[0056] Sodium dihydrogen phosphate 6.0g

[0058] Fructose 1.0g

[0060] Add water for injection to 2000ml

[0061] Process:

[0062] (1) Take water for injection at 45°C±5°C with 80% of the prepared amount, add raw and auxiliary materials and stir until completely dissolved, then cool to 25°C±5°C; measure the pH value, add 1mol / L NaOH solution to adjust the pH value to 5.3, Add water to nearly full volume.

[0063] (2) Add medicinal charcoal and stir thoroughly for 30 minutes at 25°C±5°C, filter and decarbonize, and add water to the full amount.

[0064] (3) Filter with a 0.45 μm microporous membrane and then a 0.22 μm microporous membrane, and take samples to determine the pH value and the content of active ingredients.

[0065] (4) Fill and seal ampoule with 2ml e...

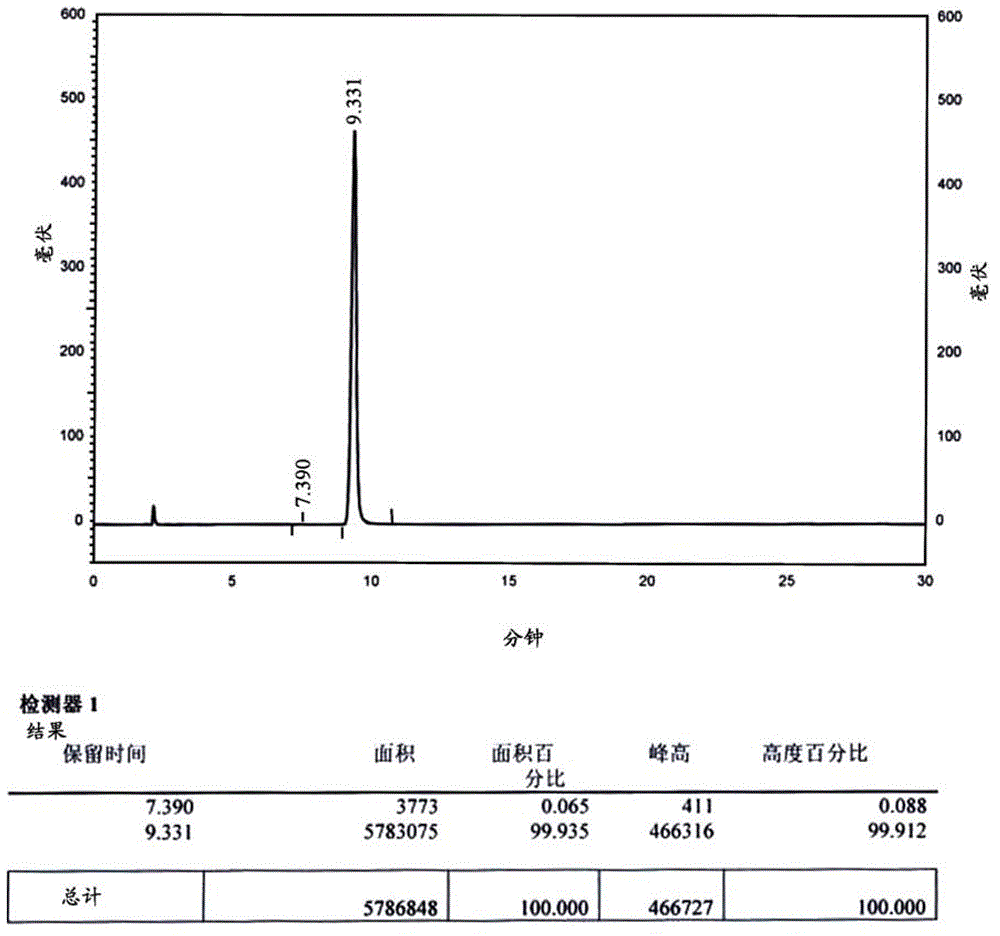

Embodiment 2

[0066] Example 2 1000 pieces

[0067] Prescription: Specification 4ml: 30mg

[0068] Ambroxol Hydrochloride 30.0g

[0069] Citric acid 4.0g

[0070] Sodium dihydrogen phosphate 8.0g

[0071] Potassium chloride 34.0g

[0072] Sorbitol 2.0g

[0073] Sodium bisulfite 4.0g

[0074] Add water for injection to 4000ml

[0075] Process:

[0076] (1) Take water for injection at 50°C±5°C with 60% of the prepared amount, add raw and auxiliary materials and stir until completely dissolved, then cool to 35°C±5°C; measure the pH value, add 0.8 mol / L NaOH solution to adjust the pH value to 4.7 , add water to nearly full amount.

[0077] (2) Add medical charcoal and stir thoroughly for 30 minutes at 35°C±5°C, filter and decarbonize, and add water to the full amount.

[0078] (3) Filter with a 0.45 μm microporous membrane and then a 0.22 μm microporous membrane, and take samples to determine the pH value and the content of active ingredients.

[0079] (4) Fill each 4ml ampoule int...

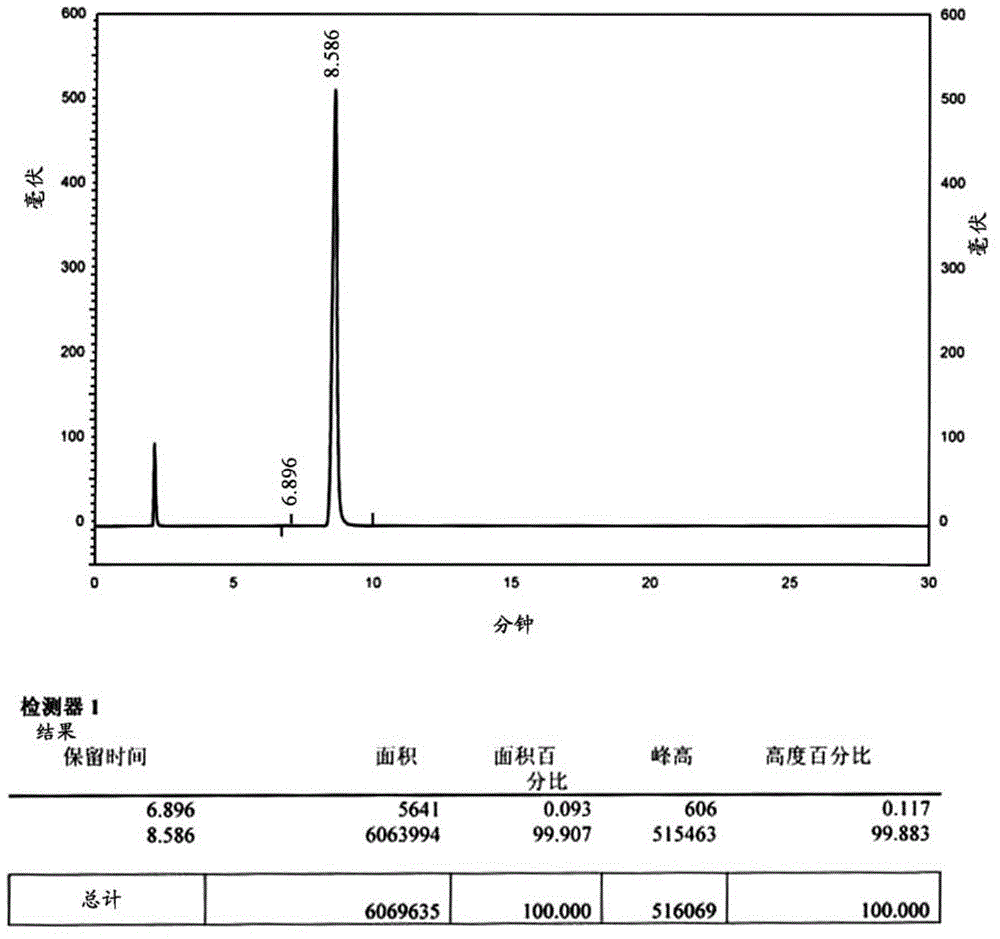

Embodiment 3

[0080] Example 3 1000 pieces

[0081] Prescription: Specification 10ml: 75mg

[0082] Ambroxol Hydrochloride 75.0g

[0083] Citric acid 10.0g

[0084] Sodium dihydrogen phosphate 10.0g

[0085] Sodium chloride 180g

[0086] Fructose 1.0g

[0087] Sodium Metabisulfite 5.0g

[0088] Add water for injection to 10000ml

[0089] Process:

[0090] (1) Take water for injection at 60°C±5°C with 70% of the prepared amount, add raw and auxiliary materials and stir until completely dissolved, then cool to 40°C±5°C; measure the pH value, add 0.6mol / L NaOH solution to adjust the pH value to 4.9 , add water to nearly full amount.

[0091] (2) Add medicinal charcoal and stir thoroughly for 30 minutes at 40°C±5°C, filter and decarbonize, and add water to the full amount.

[0092] (3) Filter with a 0.45 μm microporous membrane and then a 0.22 μm microporous membrane, and take samples to determine the pH value and the content of active ingredients.

[0093] (4) Fill and seal 10ml o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com