Method for extracting cyanidin from purple common yam rhizome

A technology for yam and anthocyanin, which is applied in the field of extracting anthocyanin from purple yam, can solve the problems of unfavorable industrial production, long time consumption, cumbersomeness and the like, and achieve the effect of reducing harm to the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

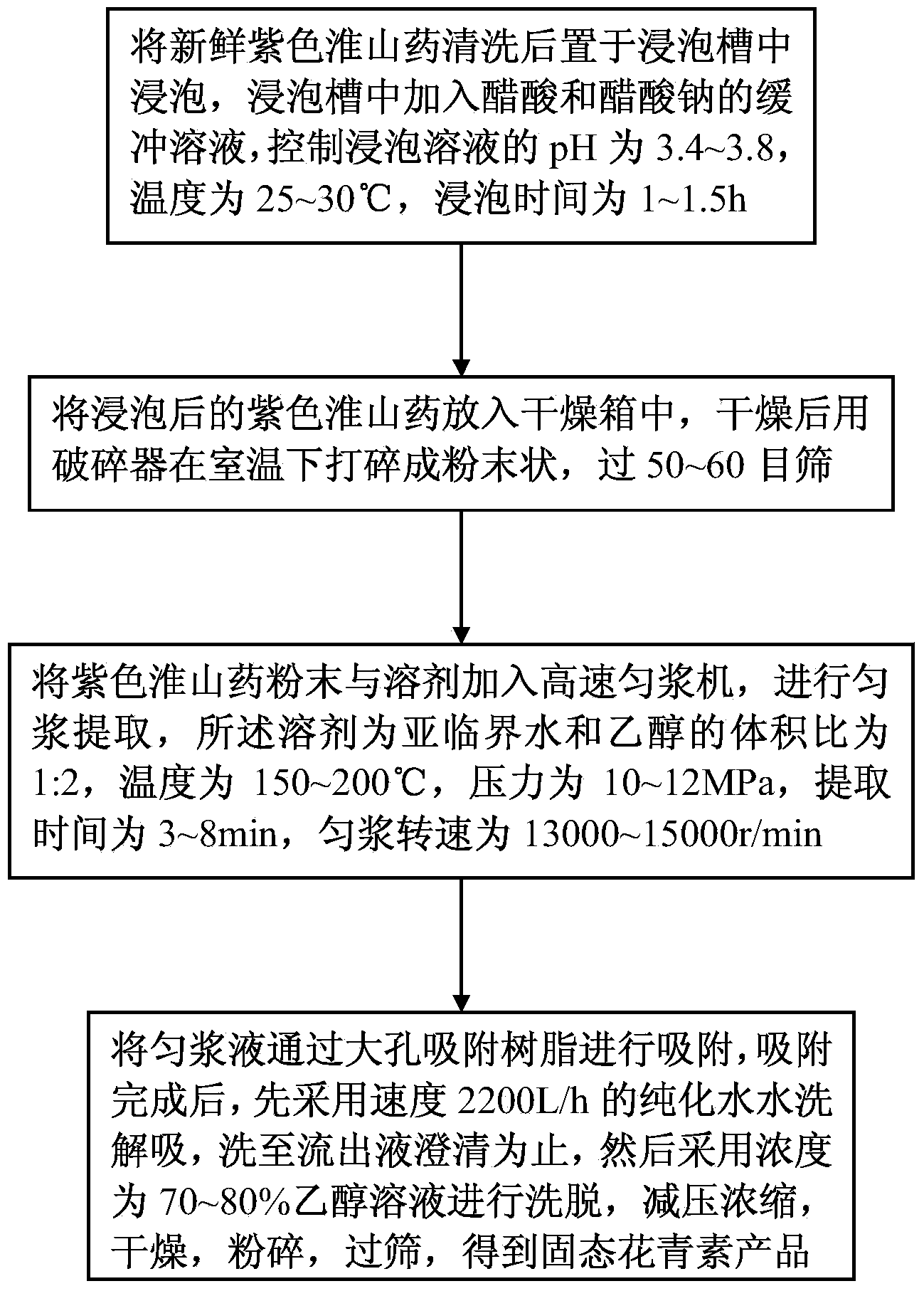

[0021] A method for extracting anthocyanins from purple yam, comprising the following steps:

[0022] Step 1. Wash the fresh purple Chinese yam and soak it in a soaking tank. Add a buffer solution of acetic acid and sodium acetate to the soaking tank. Control the pH of the soaking solution to 3.4, the temperature to 25°C, and the soaking time to 1 hour;

[0023] Step 2. Put the soaked purple Chinese yam into a drying oven. The temperature in the drying oven is 32°C, and the drying time is 15 minutes. After drying, use a crusher to crush it into powder at room temperature, and pass through a 50-mesh sieve. ;

[0024] Step 3, adding the purple yam powder and solvent into a high-speed homogenizer with a mass ratio of 1:30 for homogenate extraction. The solvent is subcritical water and ethanol with a volume ratio of 1:2 and a temperature of 150°C. The pressure is 10MPa, the extraction time is 3min, and the homogenization speed is 13000r / min;

[0025] Step 4. Adsorb the homogenat...

Embodiment 2

[0027] A method for extracting anthocyanins from purple yam, comprising the following steps:

[0028] Step 1. Wash the fresh purple Chinese yam and soak it in a soaking tank. Add a buffer solution of acetic acid and sodium acetate to the soaking tank. Control the pH of the soaking solution to 3.6, the temperature to 28°C, and the soaking time to 1.2 hours;

[0029] Step 2. Put the soaked purple Chinese yam into a drying oven. The temperature in the drying oven is 34°C, and the drying time is 17 minutes. After drying, use a crusher to crush it into powder at room temperature, and pass through a 55-mesh sieve. ;

[0030] Step 3, adding the purple yam powder and solvent into a high-speed homogenizer at a mass ratio of 1:40 for homogenate extraction. The solvent is subcritical water and ethanol at a volume ratio of 1:2, and the temperature is 180°C. The pressure is 11MPa, the extraction time is 5min, and the homogenization speed is 14000r / min;

[0031] Step 4. Adsorb the homogen...

Embodiment 3

[0033] A method for extracting anthocyanins from purple yam, comprising the following steps:

[0034] Step 1. Wash the fresh purple Chinese yam and soak it in a soaking tank. Add a buffer solution of acetic acid and sodium acetate to the soaking tank. Control the pH of the soaking solution to 3.8, the temperature to 30°C, and the soaking time to 1.5 hours;

[0035] Step 2. Put the soaked purple Chinese yam into a drying oven. The temperature in the drying oven is 36°C, and the drying time is 20 minutes. After drying, use a crusher to crush it into powder at room temperature, and pass through a 60-mesh sieve. ;

[0036] Step 3, adding purple Chinese yam powder and solvent into a high-speed homogenizer with a mass ratio of 1:45 to perform homogenate extraction, the solvent is subcritical water and ethanol with a volume ratio of 1:2, and the temperature is 200°C. The pressure is 12MPa, the extraction time is 8min, and the homogenization speed is 15000r / min;

[0037] Step 4. Ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com