Wax removal liquid and application and preparation method thereof

A technology for removing wax water and active agent, applied in the field of metal surface treatment, can solve the problems of consuming large solvent stock solution, unfavorable environmental protection requirements, flammability, etc., and achieve the effect of reducing human body damage, avoiding surface fogging, and stable storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

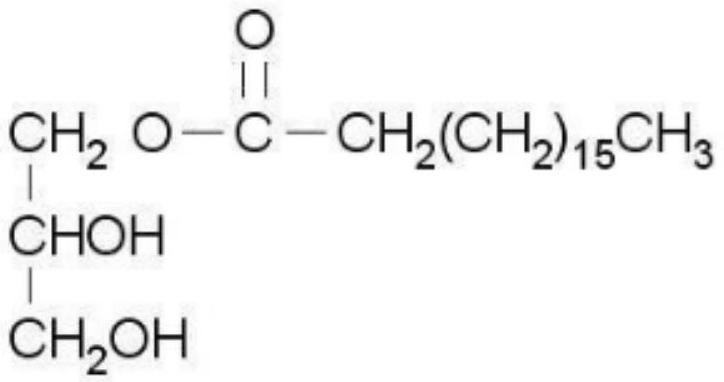

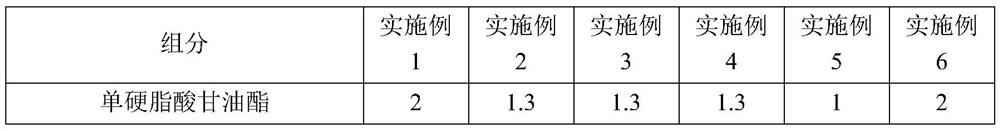

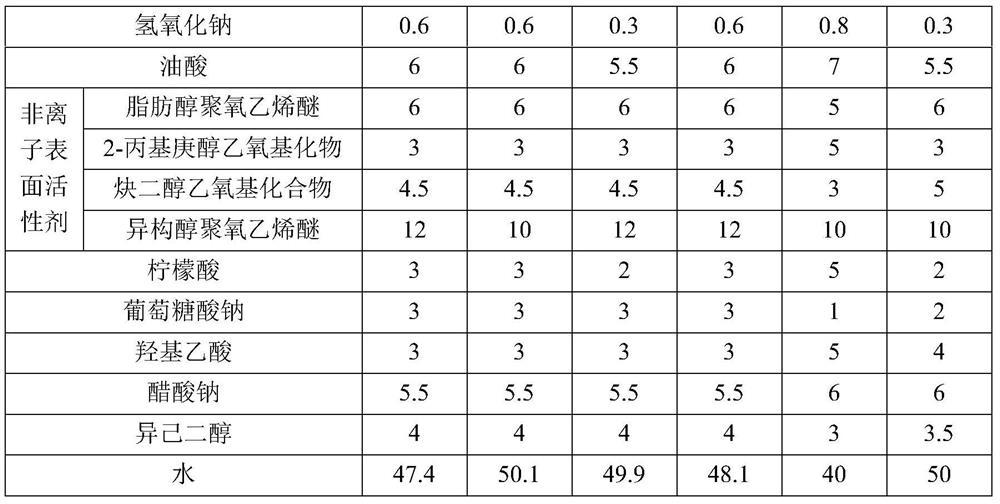

[0084] A wax removal water, consisting of the following components by weight: 6 kg of oleic acid, 3 kg of glycolic acid, 3 kg of citric acid, 0.3 kg of sodium gluconate, 0.6 kg of sodium hydroxide, 5.5 kg of sodium acetate, and 25.5 kg of nonionic surfactant , 2 kg of glyceryl monostearate, 4 kg of isohexanediol and 47.4 kg of water. Among them, the nonionic surfactant consists of 6kg of fatty alcohol polyoxyethylene ether, 3kg of 2-propylheptyl alcohol ethoxylate, 4.5kg of acetylenic glycol ethoxylate and 12kg of isomeric alcohol polyoxyethylene ether composition. In addition, it should be noted that the number of polyoxyethylene in the fatty alcohol polyoxyethylene ether in this embodiment is 15.

[0085] That is, the dewax water of the present embodiment comprises 6% of oleic acid, 3% of glycolic acid, 3% of citric acid, 0.3% of sodium gluconate, 0.6% of sodium hydroxide, 5.5% of sodium acetate, fatty alcohol polyoxygen Vinyl Ether 6%, 2-Propylheptanol Ethoxylate 3%, Alky...

Embodiment 2

[0092] A kind of wax-removing water, its composition ratio is specifically shown in Table 1. The number of polyoxyethylene in the fatty alcohol polyoxyethylene ether in this embodiment is 10.

[0093] The preparation method of dewaxing water is as follows:

[0094] S1: In parts by weight, sodium hydroxide, oleic acid, and glycerol monostearate are stirred and mixed for the first time to obtain a first mixed liquid. The temperature of the reaction kettle was kept at 100° C., the stirring time was 20 minutes, and the stirring speed was 500 r / min.

[0095] S2: After the first mixed liquid is cooled to normal temperature, add fatty alcohol polyoxyethylene ether, 2-propylheptyl alcohol ethoxylate, acetylenic glycol ethoxylate, isomeric alcohol polyoxyethylene ether, isohexanediol Add the first mixed solution to obtain the second mixed solution.

[0096] S3: Completely dissolve citric acid, sodium gluconate, sodium acetate and glycolic acid in water to obtain a third mixed soluti...

Embodiment 3-6

[0099] A wax removal water, the difference from Example 1 is that the amount of each component of the wax removal water is different, see Table 1 for details. The rest are the same as those in Implementation 1, and will not be repeated here.

[0100] Each group distribution ratio of table 1 embodiment 1-6

[0101]

[0102]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com