Low-smoke halogen-free high-temperature-resistant flame-retardant vinyl ester resin and preparation method thereof

A vinyl ester resin and high-temperature-resistant technology, which is applied in the field of low-smoke, halogen-free, high-temperature flame-retardant vinyl ester resin and its preparation, can solve problems such as unstable preparation process, poor flame-retardant effect, and environmental protection, and achieve Precise formula design, moderate viscosity, excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

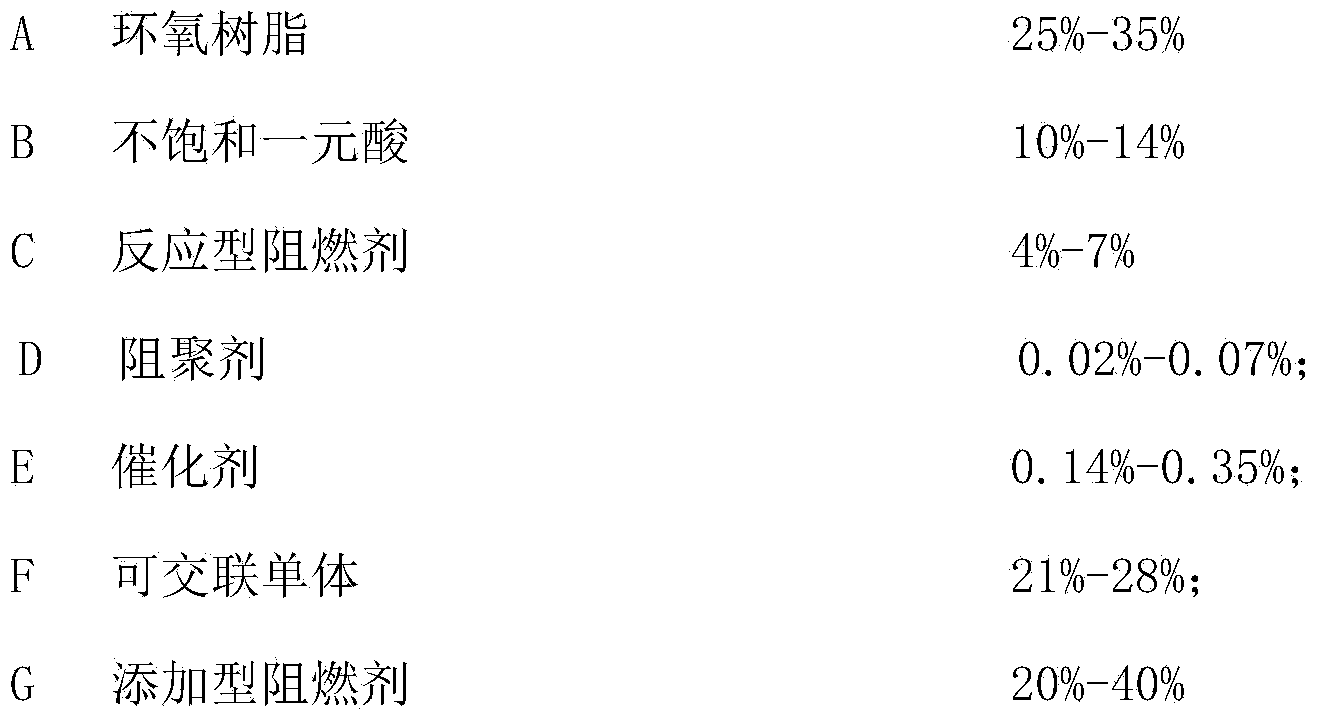

[0024] Weigh each component according to the following mass:

[0025]

[0026]

[0027] Put raw materials A, B, C, D, and E into the reaction kettle, react at 110°C for 4 hours, then dissolve in F, add G after cooling down to room temperature, stir evenly, and store in airtight.

Embodiment 2

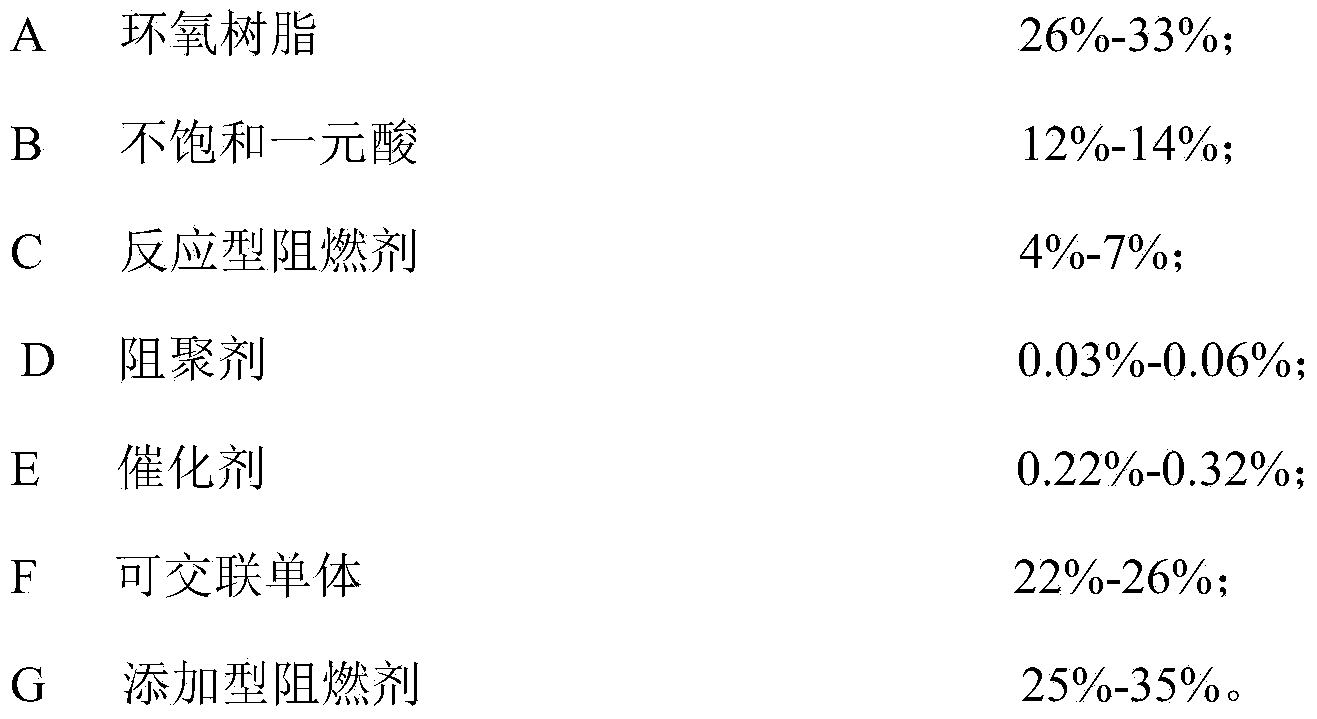

[0029]

[0030] Put raw materials A, B, C, D, and E into the reactor, react at 120°C for 2 hours, then dissolve in F, add G after cooling down to room temperature, stir evenly, and store in airtight.

Embodiment 3

[0032]

[0033] Put raw materials A, B, C, D, and E into the reactor, react at 100°C for 5 hours, then dissolve in F, add G after cooling down to room temperature, stir evenly, and store in airtight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com