Composite flame-resistant material for wire and cable sheaths

A composite flame retardant, wire and cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem of different sheaths, torsion resistance, elongation at break resistance to environmental cracking, acid and alkali resistance, high and low temperature resistance Can not achieve the ideal effect, can not be applied and other problems, to achieve the effect of excellent performance, good anti-torsion performance, excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

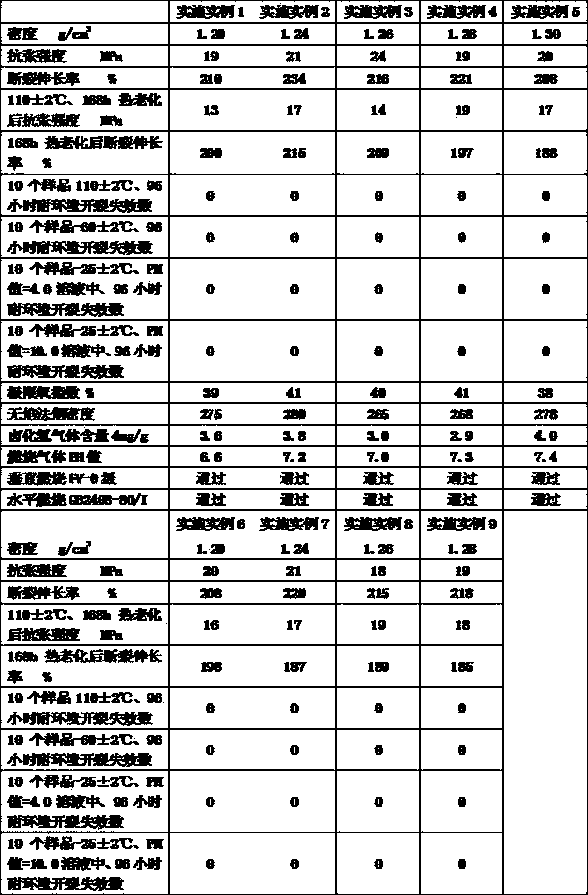

Examples

Embodiment 1

[0023] A composite flame-retardant material for wire and cable sheaths, characterized in that it is composed of the following raw materials in parts by weight:

[0024] Polyethylene resin: 65 parts;

[0025] Ethylene-vinyl acetate copolymer: 22 parts;

[0026] Epoxy resin: 5 parts;

[0027] Polyethylene wax: 2 parts;

[0028] Ammonium polyacrylate: 1 part;

[0029] Nano silicon nitride: 2 parts;

[0030] Dioctyl oxalate: 30 parts;

[0031] Commercially available polyester plasticizer of model PN-850: 10 parts;

[0032] Trimellitic anhydride: 3 parts;

[0033] Magnesium hydroxide: 30 parts;

[0034] Carbon black: 6 parts;

[0035] Antioxidant of commercially available model T501: 1 part.

[0036] A composite flame-retardant material for wire and cable sheaths according to the present invention is obtained by accurately weighing the above-mentioned components, adding them to a high-speed mixer for mixing, stirring evenly, and transferring them to a twin-screw rubber mix...

Embodiment 2

[0038] A composite flame-retardant material for wire and cable sheaths, characterized in that it is composed of the following raw materials in parts by weight:

[0039] Polyethylene resin: 65 parts;

[0040] Ethylene-vinyl acetate copolymer: 22 parts;

[0041] Epoxy resin: 5 parts;

[0042] Polyethylene wax: 2 parts;

[0043] Ammonium polyacrylate: 1 part;

[0044] Nano silicon carbide: 2 parts;

[0045] Dioctyl oxalate: 30 parts;

[0046] Commercially available polyester plasticizer of model PN-850: 10 parts;

[0047] Trimellitic anhydride: 3 parts;

[0048] Aluminum hydroxide: 30 parts;

[0049] Carbon black: 6 parts;

[0050] Antioxidant of commercially available model T501: 1 part.

[0051] A composite flame-retardant material for wire and cable sheaths according to the present invention is obtained by accurately weighing the above-mentioned components, adding them to a high-speed mixer for mixing, stirring evenly, and transferring them to a twin-screw rubber mixe...

Embodiment 3

[0053] A composite flame-retardant material for wire and cable sheaths, characterized in that it is composed of the following raw materials in parts by weight:

[0054] Polyethylene resin: 65 parts;

[0055] Ethylene-vinyl acetate copolymer: 22 parts;

[0056] Epoxy resin: 5 parts;

[0057] Polyethylene wax: 2 parts;

[0058] Ammonium polyacrylate: 1 part;

[0059] Nano zirconia: 2 parts;

[0060] Dioctyl oxalate: 30 parts;

[0061] Commercially available polyester plasticizer of model PN-850: 10 parts;

[0062] Trimellitic anhydride: 3 parts;

[0063] Magnesium hydroxide: 30 parts;

[0064] Carbon black: 6 parts;

[0065] Antioxidant of commercially available model T501: 1 part.

[0066] A composite flame-retardant material for wire and cable sheaths according to the present invention is obtained by accurately weighing the above-mentioned components, adding them to a high-speed mixer for mixing, stirring evenly, and transferring them to a twin-screw rubber mixer, etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com