Graphene/metal matrix composite material and preparation method thereof

A composite material and graphene technology, applied in the field of graphene/metal matrix composite material and its preparation, can solve the problem that the comprehensive performance cannot meet the actual needs, and achieve the effects of high conductivity, high efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

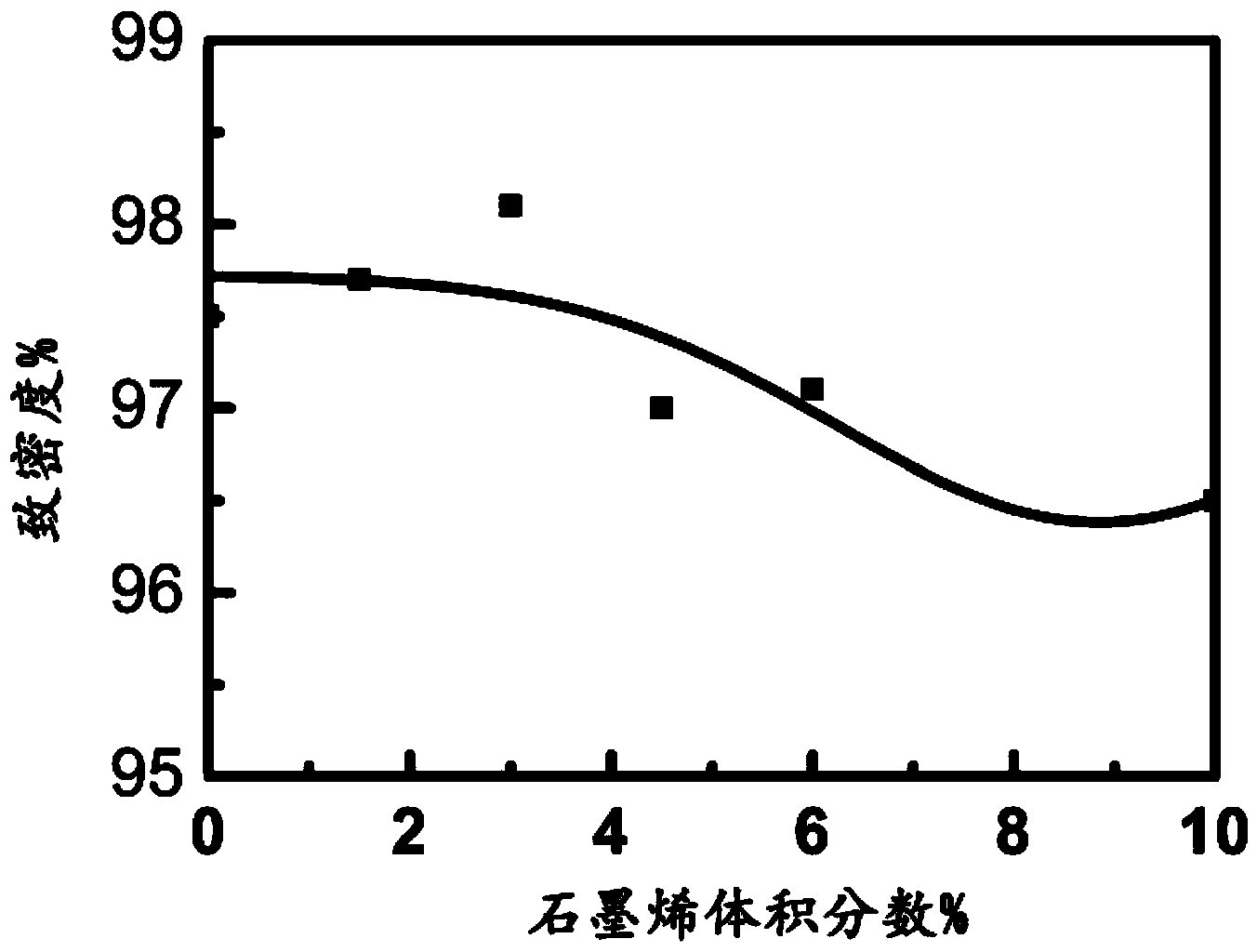

Examples

Embodiment 1

[0027] The average particle size of graphite powder in this embodiment is 325 mesh. The Hummer method is used. The details are as follows: first weigh 0.2g graphite and 0.5gK 2 S 2 O 4 And 0.5g P 2 O 5 Measure 4mL of concentrated sulfuric acid and mix it evenly, and put it in a water bath at 80°C and keep stirring for four hours before taking it out. Add 12mL concentrated sulfuric acid to the treated solution, and slowly add 2g KMnO below 20°C (addition rate is 0.1 g / min) 4 . Join KMnO 4 Afterwards, it was stirred at a constant temperature for 2 hours at 35°C. Then add it to 25 mL of distilled water, and use concentrated sulfuric acid to absorb water and exothermic heat, so that the graphite flakes are completely oxidized and separated. The resultant was added to 70 mL of distilled water, and kept at 70°C for 1 hour. Add 3mL hydrogen peroxide to the solution to remove excess KMnO 4 , Wash with alcohol to the solution pH=7, ultrasonically disperse for 1 hour, and dry the solu...

Embodiment 2

[0029] The experimental conditions for chemically exfoliating graphene are the same as in Example 1. After the graphene oxide is obtained, it is heated in a tube furnace, and heated to 700 degrees Celsius in an argon atmosphere for 2 hours to obtain thermally reduced graphene.

Embodiment 3

[0031] The experimental conditions for chemical exfoliation of graphene are the same as in Example 1. After obtaining graphene oxide, disperse it in an aqueous solution, add 0.5 mg / mL of the same volume of hydrazine hydrate solution, and heat it in a water bath at 90°C for 30 minutes. After filtration, hydrazine hydrate chemically reduced graphene is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com