Oxygen-enrichment combustion assisting method of oxygen enrichment device of combustor of cement decomposing furnace

A cement decomposition furnace, oxygen-enriched combustion-supporting technology, applied in the direction of combustion method, combustion air/fuel supply, control of combustion, etc., can solve the problems of large coal consumption, large amount of coal, and increased exhaust gas discharge of the decomposition furnace. Achieve the effects of complete fuel combustion, lower coal ignition point, and higher combustion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

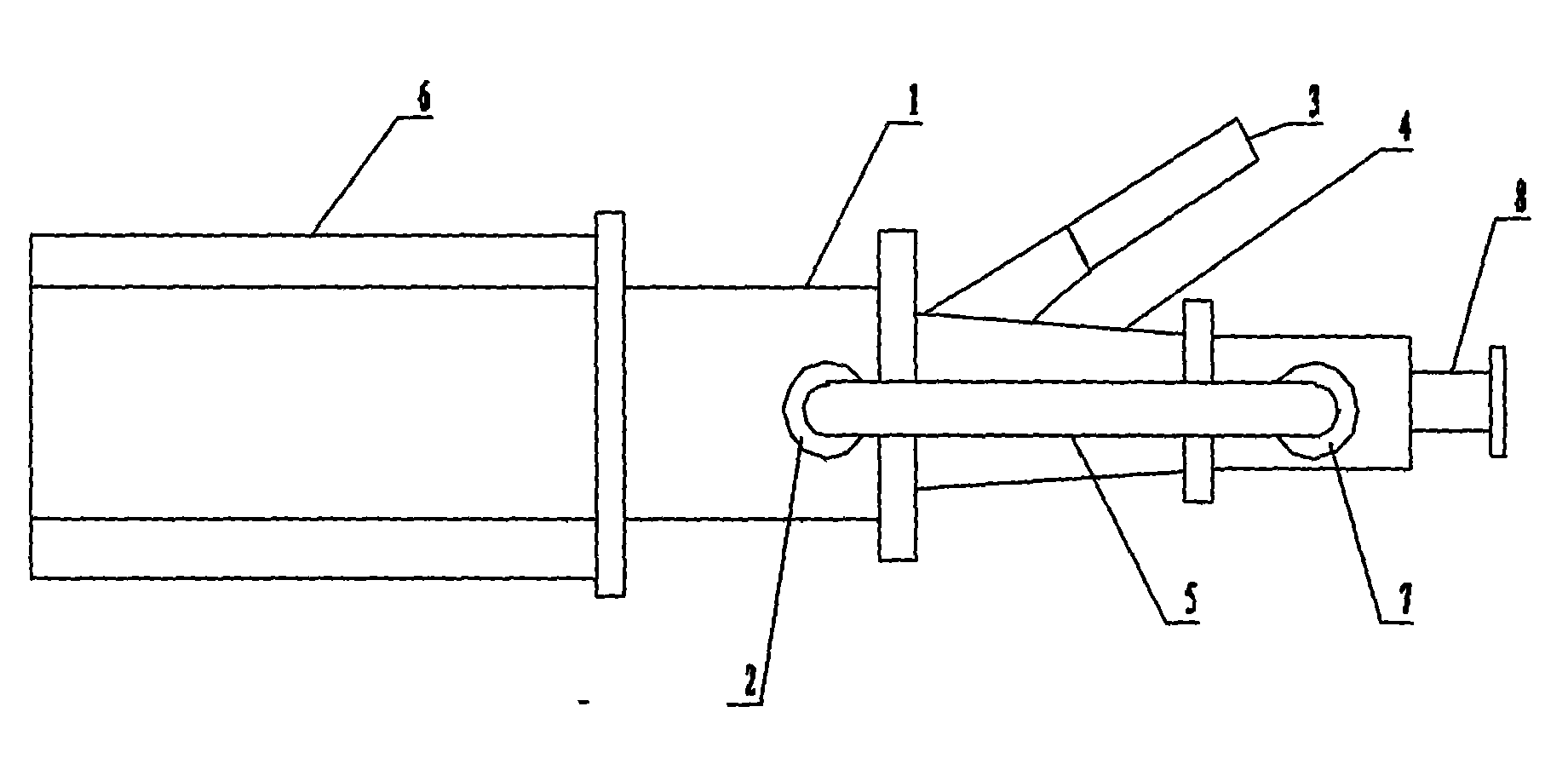

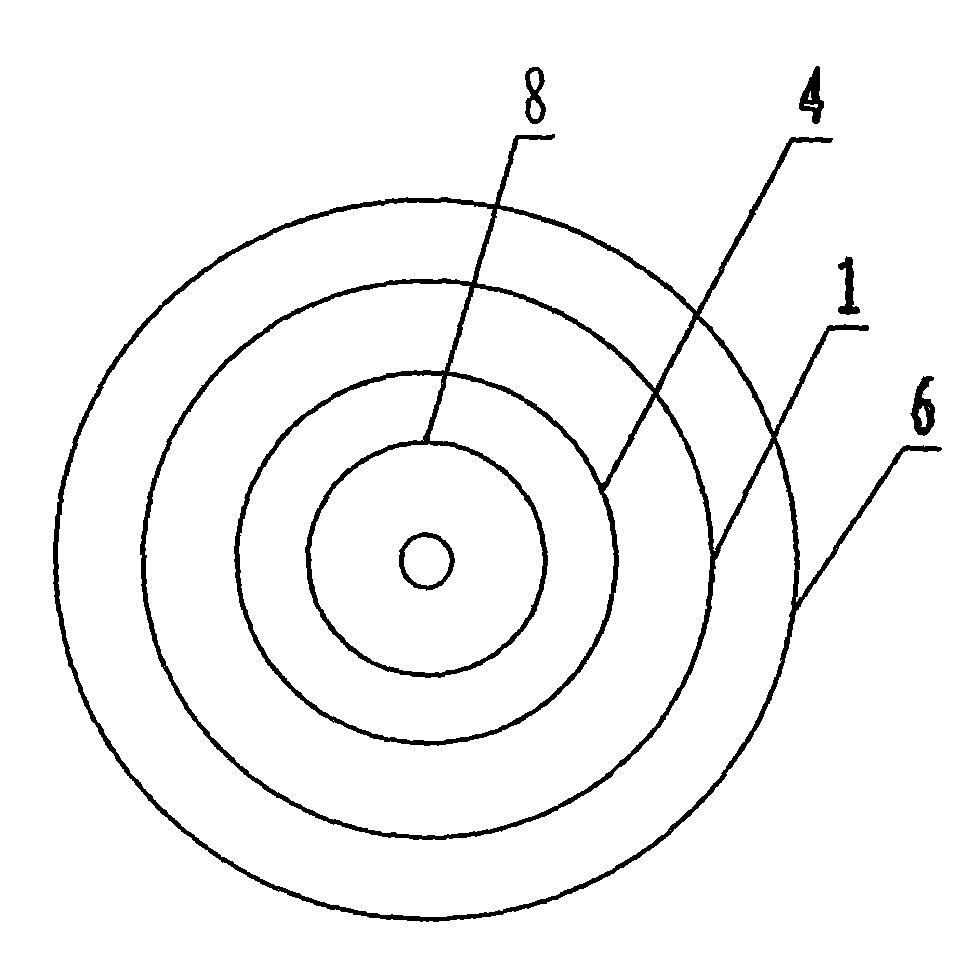

[0020] As shown in the figure; an oxygen-enriching device for a burner of a cement decomposition furnace is composed of a kiln tail outer pipe 1, a kiln tail outer air inlet pipe 2, a kiln tail pulverized coal air flow pipe 3, a kiln tail coal air pipe 4, Kiln tail oxygen-enriched air channel 5, kiln tail refractory concrete 6, kiln tail air inlet pipe 7, kiln tail internal air pipe 8; cement calciner burner oxygen-enrichment device is equipped with four pipes, pipe-in-pipe coaxial arrangement: The kiln tail central pipe 8 is provided with a kiln tail coal wind pipe 4, and the kiln tail coal wind pipe 4 is provided with a kiln tail outer layer pipe 1, and the kiln tail outer layer pipe 1 is provided with a kiln tail refractory concrete 6; one end of each pipe is connected to the kiln tail The outlet of the internal air duct 8 is arranged flush, which is the total outlet of the kiln tail; the tail end of the kiln tail internal air duct 8 constitutes the inlet, and the kiln tail ...

Embodiment 2

[0022] The kiln tail oxygen-enriched air channel 5 is set between the kiln tail outer layer air inlet pipe opening 2 and the kiln tail air inlet pipe port 7, and the kiln tail oxygen-enriched air duct 5 pipe end in the kiln tail outer layer air inlet pipe port 2 is reserved Oxygen-enriched air inlet; an oxygen-enriched delivery pipe mouth is arranged on the kiln tail internal air duct 8 .

Embodiment 3

[0024] The enriched oxygen with a concentration of 23% to 50% passes through the air inlet of the kiln tail oxygen-enriched air channel 5 in the outer layer of the kiln tail air inlet pipe 2, and the enriched oxygen enters the kiln tail air inlet pipe 7 through the kiln tail oxygen-enriched air duct 5 , enter the kiln tail internal air duct 8 through the kiln tail air inlet pipe 7, and enter the cement decomposition furnace through the outlet of the kiln tail internal air duct 8; at the same time, the air flow of coal powder is input into the cement decomposition furnace through the kiln tail coal air duct 4. powder; the concentration of the inner air duct 8 at the kiln tail is 23% to 50%, and the oxygen-enriched internal air flow is fully mixed with the pulverized coal air flow at the outlet. The high temperature of 1300 ℃ in the field, the oxygen-enriched and pulverized coal air flow burns rapidly, and after the temperature of the combustion field can be increased by 450 ℃, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com