Preparation method of RRAM (Resistive Random Access Memory)

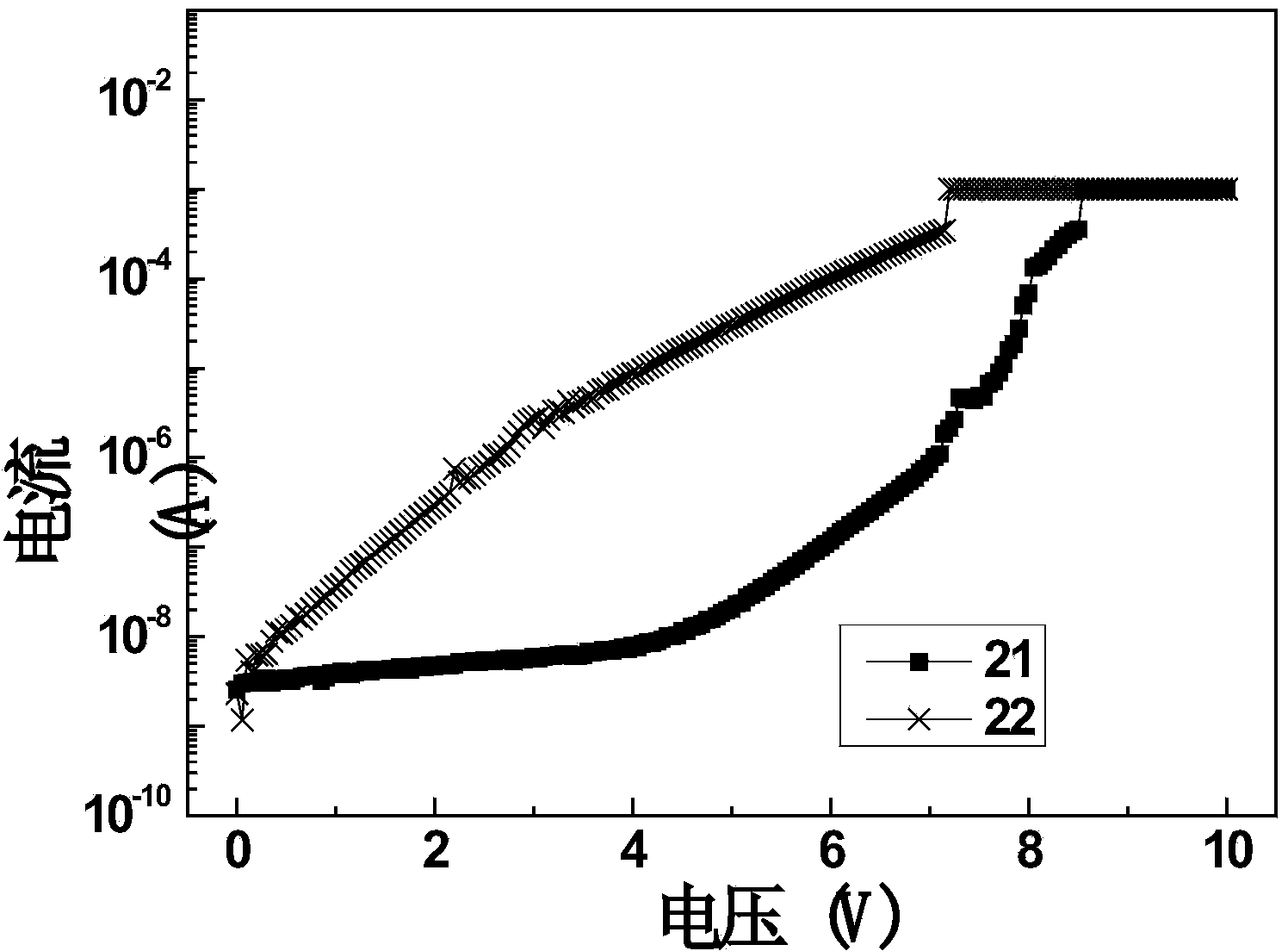

A resistive memory and resistive switching technology, which is used in gaseous chemical plating, metal material coating process, electrical components, etc., can solve the problems that limit the wide application of ALD technology, the high resistance state resistance value changes in a large range, and the device resistance change is stable. It can improve the resistance switching characteristics, the erasing and writing voltage can be adjusted, and the high density can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

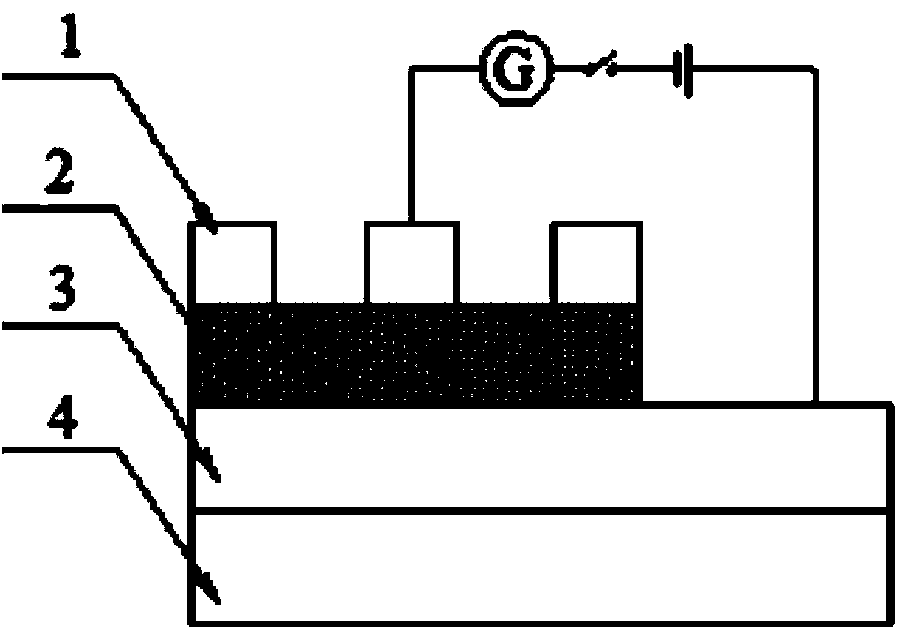

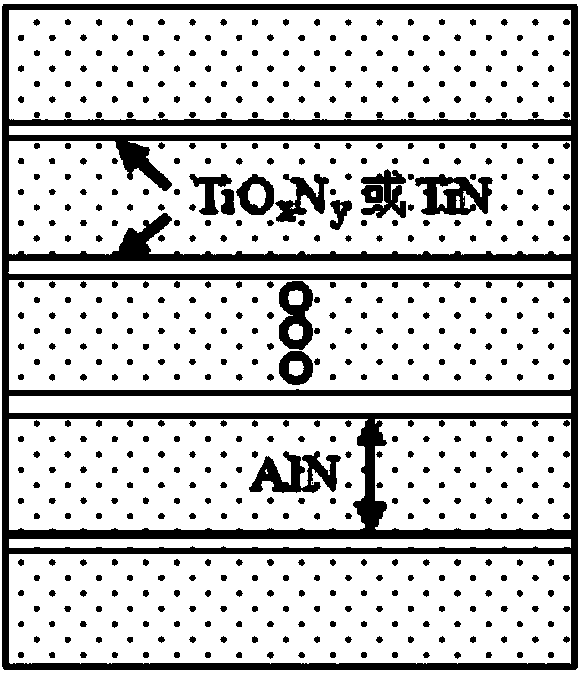

[0035] Aluminum nitride is used as the matrix of the resistive dielectric layer, and titanium oxynitride is used as the doped layer. Using titanium tetraisopropoxide as the second precursor, N 2 / H 2 (1:1) mixed gas plasma as a reactant, including the following steps:

[0036] 1) Using magnetron sputtering method on SiO 2(300nm) / Si(100) substrate 4 surface preparation inert metal Pt bottom electrode 3, the bottom electrode 3 thickness of gained is 150nm, and the temperature of preparation is 150 ℃, and deposition main gas is argon gas, and pressure is 0.5Pa, and sputtering power It is 300W.

[0037] 2) Using plasma-enhanced atomic layer deposition, using trimethylaluminum as the first precursor and titanium tetraisopropoxide as the second precursor, N 2 / H 2 The plasma of (1:1) mixed gas is the first and the second reactant, and argon is used as the inert gas for cleaning, and the aluminum nitride layer matrix film of 2 cycles is deposited on the Pt bottom electrode 3 ear...

Embodiment 1-2

[0040] Other conditions are the same as embodiment 1-1, the first and second reactants are changed into N 2 / H 2 (5:1) mixed gas plasma, the number of cycles of the aluminum nitride layer matrix film is changed to 4, the thickness of the matrix layer is 0.32nm, and finally the single atomic layer titanium oxynitride doped aluminum nitride film (AlN :Ti=4:1).

Embodiment 2-1

[0050] Aluminum nitride is used as the substrate of the resistive dielectric layer, titanium nitride is used as the doped layer, tetrakis(dimethylamino)titanium is used as the second precursor, and N 2 / H 2 (1:5) mixed gas plasma as a reactant, including the following steps:

[0051] 1) The inert metal Au bottom electrode 3 was prepared on the surface of the quartz substrate 4 by magnetron sputtering. The obtained bottom electrode 3 had a thickness of 150 nm, the temperature of the preparation was 150° C., the main gas for deposition was argon, and the pressure was 0.5 Pa. The transmitting power is 300W.

[0052] 2) Using plasma-enhanced atomic layer deposition method, using trimethylaluminum as the first precursor and tetrakis(dimethylamino)titanium as the second precursor, N 2 / H 2 The plasma of (1:5) mixed gas is the first and the second reactant, and argon is used as the inert gas for cleaning, and the aluminum nitride layer matrix film of 9 cycles is deposited on the P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com