An electrolyte and a lithium-sulfur battery comprising the same

A lithium-sulfur battery and electrolyte technology, which is applied in the field of lithium-sulfur batteries, can solve the problem that the activation voltage of lithium sulfide is not helpful, and achieve the effects of broad industrialization prospects, lower activation voltage, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

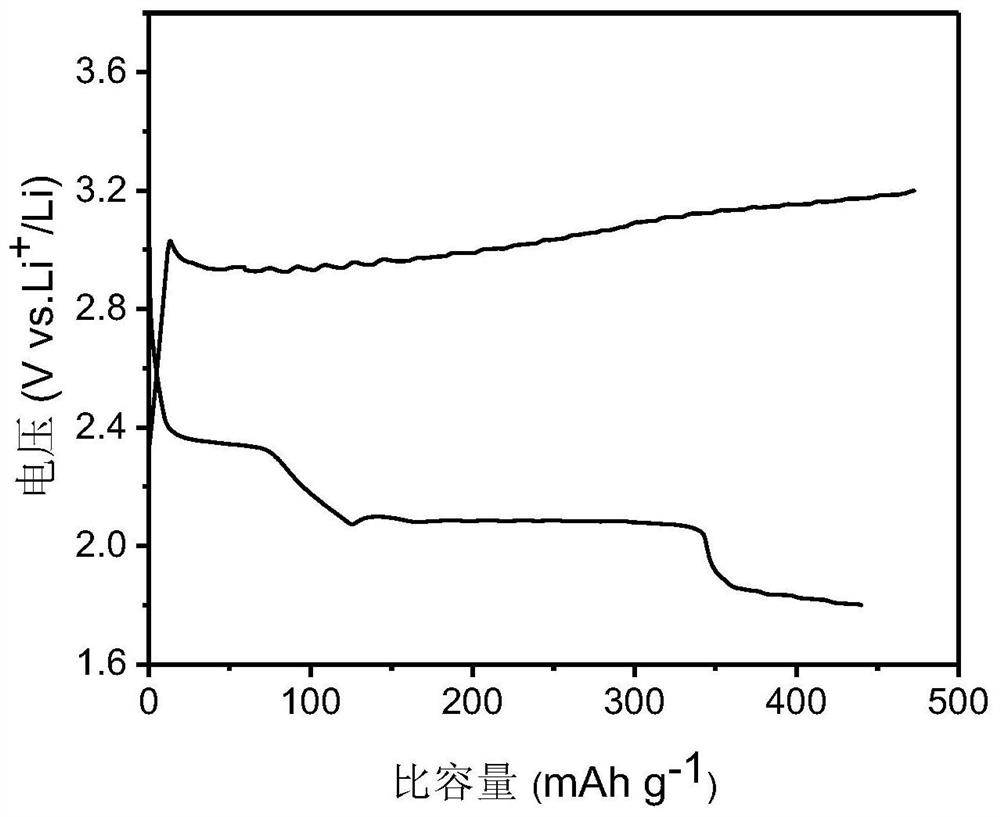

Embodiment 1

[0030] 1) Electrolyte configuration

[0031] The configuration process of the electrolyte is completed in the glove box, the water oxygen content in the glove box is less than 0.01ppm, and the temperature is at room temperature. Lithium bistrifluoromethanesulfonylimide (LiTFSI) and lithium nitrate were fully dried in a glove box, and molecular sieves were placed in absolute ethanol and allowed to stand for 12 hours.

[0032] Dissolve lithium bistrifluoromethanesulfonylimide (LiTFSI) in a mixed solvent of 20.48 g of 1,3-dioxolane and 16.67 g of 1,2-ethylene glycol dimethyl ether, so that bistrifluoromethanesulfonylimide The final concentration of lithium amide (LiTFSI) was 1M, and it was left to stand for 24 hours for later use. Take 10 grams of the prepared above-mentioned solution, add 0.2 grams of lithium nitrate to it, let it stand for 12 hours, add 0.01 grams of ethanol dropwise and shake to obtain the required electrolyte.

[0033] 2) Battery assembly and testing

[00...

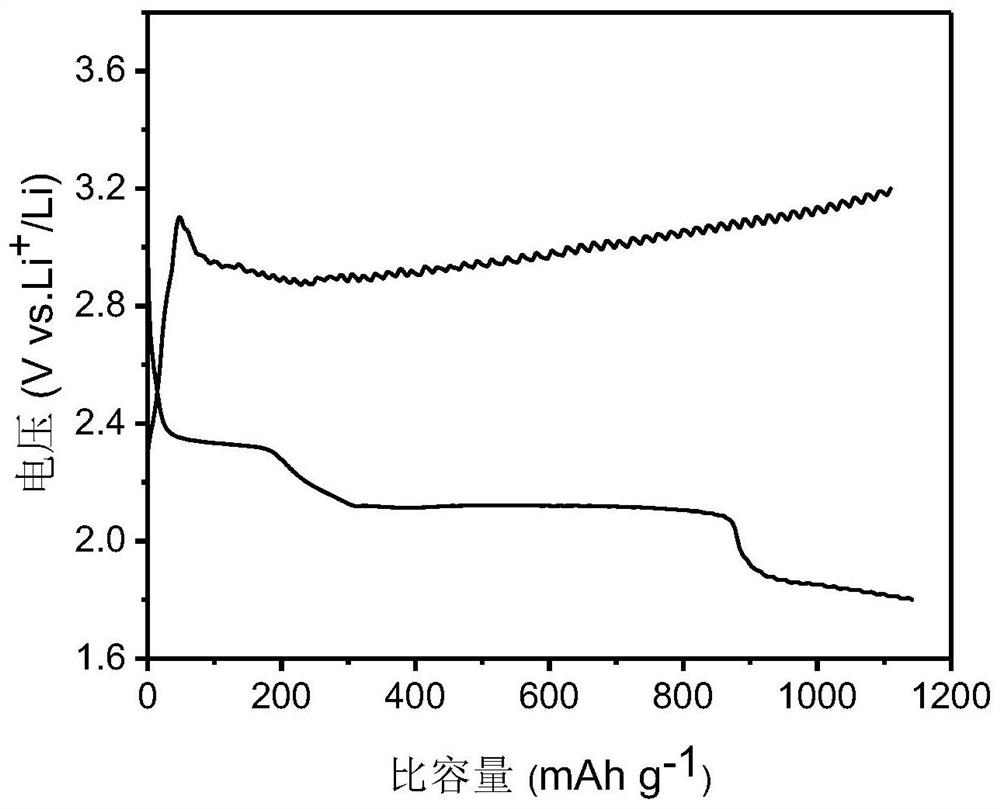

Embodiment 2

[0039] 1) Electrolyte configuration

[0040] The electrolytic solution was configured in the same manner as in Example 1 except that the amount of ethanol was replaced by 0.005 g.

[0041] 2) Battery assembly and testing

[0042] A battery was assembled and tested in the same manner as in Example 1, except that the electrolyte solution prepared in Example 2 was used.

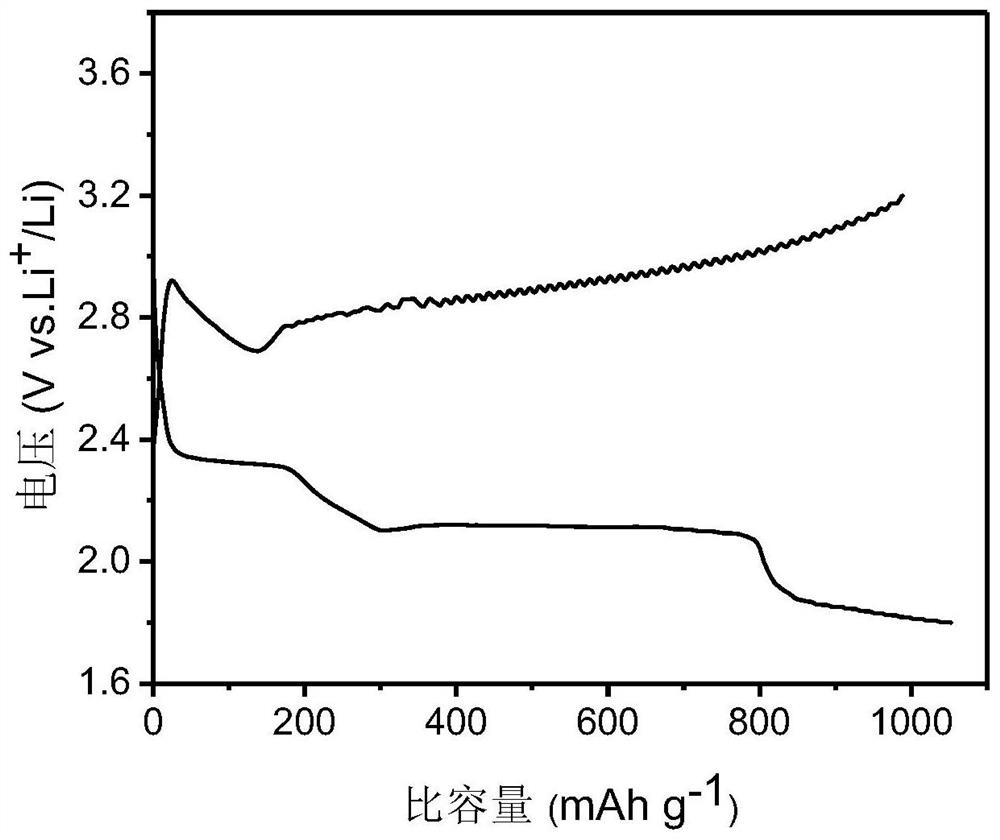

Embodiment 3

[0044] 1) Electrolyte configuration

[0045] The electrolyte solution was configured in the same manner as in Example 1, except that the amount of ethanol was replaced by 0.0025 g.

[0046] 2) Battery assembly and testing

[0047] A battery was assembled and tested in the same manner as in Example 1, except that the electrolyte solution prepared in Example 3 was used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com