Lithium-sulfur battery mixed positive electrode and preparation method thereof

A hybrid positive electrode and lithium-sulfur battery technology, applied in electrode manufacturing, battery electrodes, lithium batteries, etc., can solve the problems of poor battery cycle stability, high activation voltage for the first charge, and lower activation voltage for the first charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation steps of the lithium-sulfur battery hybrid cathode are as follows:

[0039] 1. Preparation of carbon-coated lithium sulfide electrode sheet:

[0040] (a) Using black carbon-coated lithium sulfide powder as the active material, 80 mg of the ground lithium sulfide powder coated with black carbon, 10 mg of carbon powder, and 10 mg of binder were placed in a glove box (water oxygen content <1ppm) Weigh and mix, grind evenly;

[0041] (b) dropping the uniformly ground material into a few drops of N-methylpyrrolidone (NMP) solution, and grinding while dropping, so as to perform homogenization;

[0042] (c) uniformly coating the ground slurry on the current collector to prepare an electrode sheet;

[0043] (d) placing the coated electrode sheet on a heating table at 40-80° C. for drying to obtain a carbon-coated lithium sulfide electrode sheet.

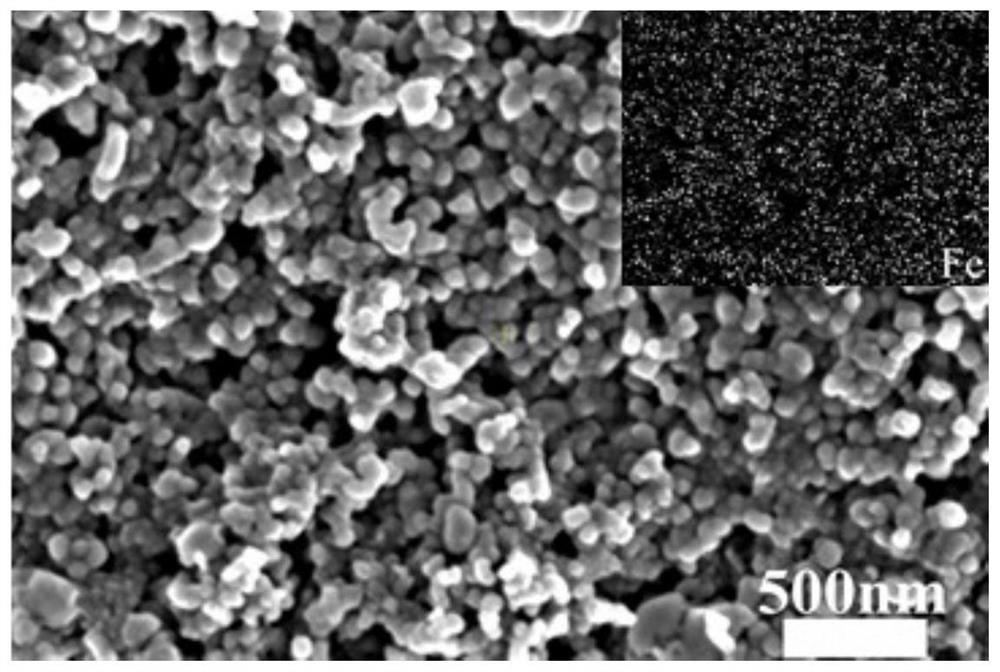

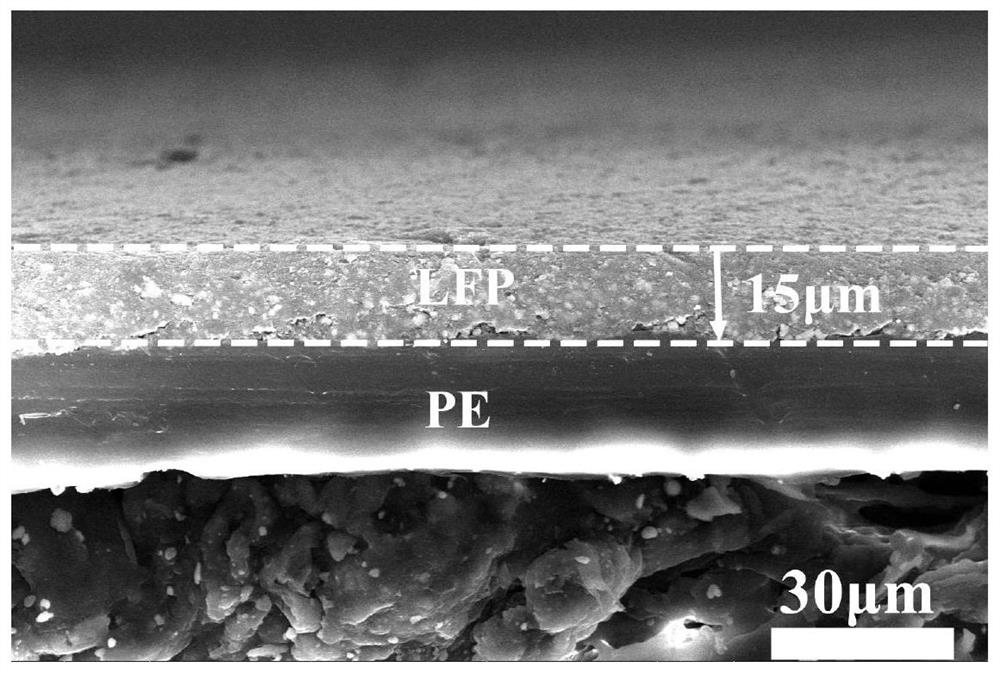

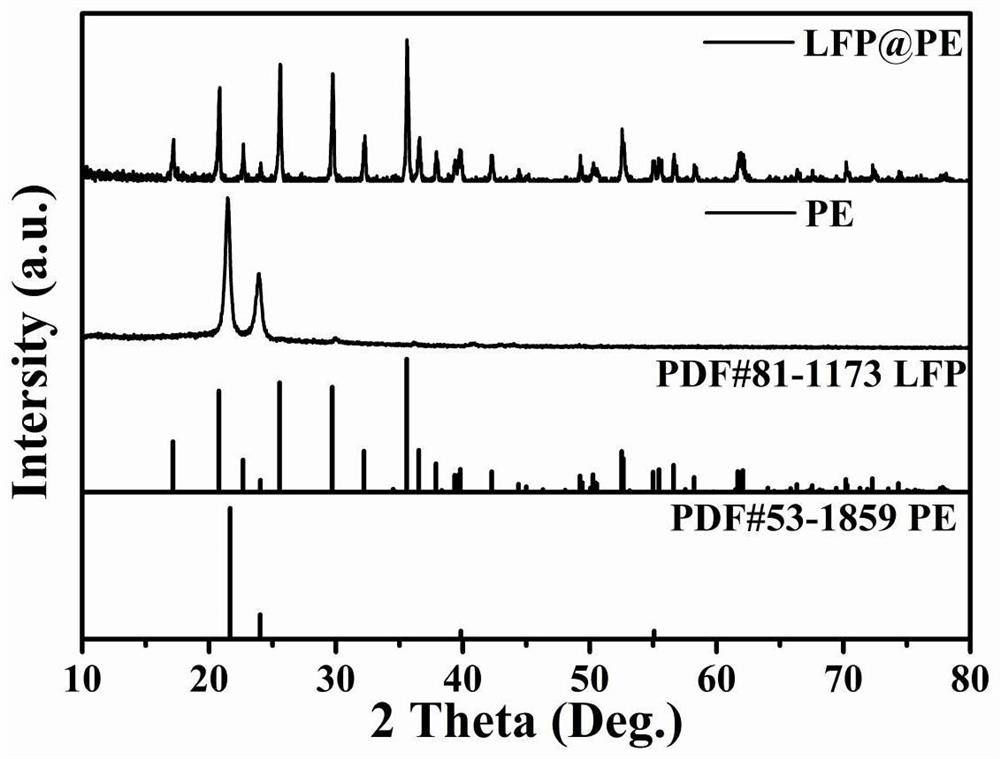

[0044] 2. Preparation of lithium iron phosphate separator:

[0045] (a) get 1g of lithium iron phosphate, 0.3g o...

Embodiment 2

[0055] The preparation steps of the lithium-sulfur battery hybrid cathode are as follows:

[0056] 1. Preparation of carbon-coated lithium sulfide electrode sheet:

[0057] (a) Using black carbon-coated lithium sulfide powder as the active material, 80 mg of the ground lithium sulfide powder coated with black carbon, 10 mg of carbon powder, and 10 mg of binder were placed in a glove box (water oxygen content <1ppm) Weigh and mix, grind evenly;

[0058] (b) dropping the uniformly ground material into N-methylpyrrolidone (NMP) solution, and grinding while dropping, so as to homogenize;

[0059] (c) uniformly coating the ground slurry on the current collector to prepare an electrode sheet;

[0060] (d) placing the coated electrode sheet on a heating table at 40-80° C. for drying to obtain a carbon-coated lithium sulfide electrode sheet.

[0061] 2. Preparation of lithium iron phosphate separator:

[0062] (a) get 0.8g lithium iron phosphate, 0.3g binder and 0.9g carbon powder a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com