Method for preparing capsaicin-loaded pH sensitive gel microsphere, and gel microsphere prepared by same

The technology of gel microspheres and capsaicin is applied in the field of preparation of pH-sensitive gel microspheres, and achieves the effects of being convenient for large-scale industrial production, reducing irritation, simple and feasible formula and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

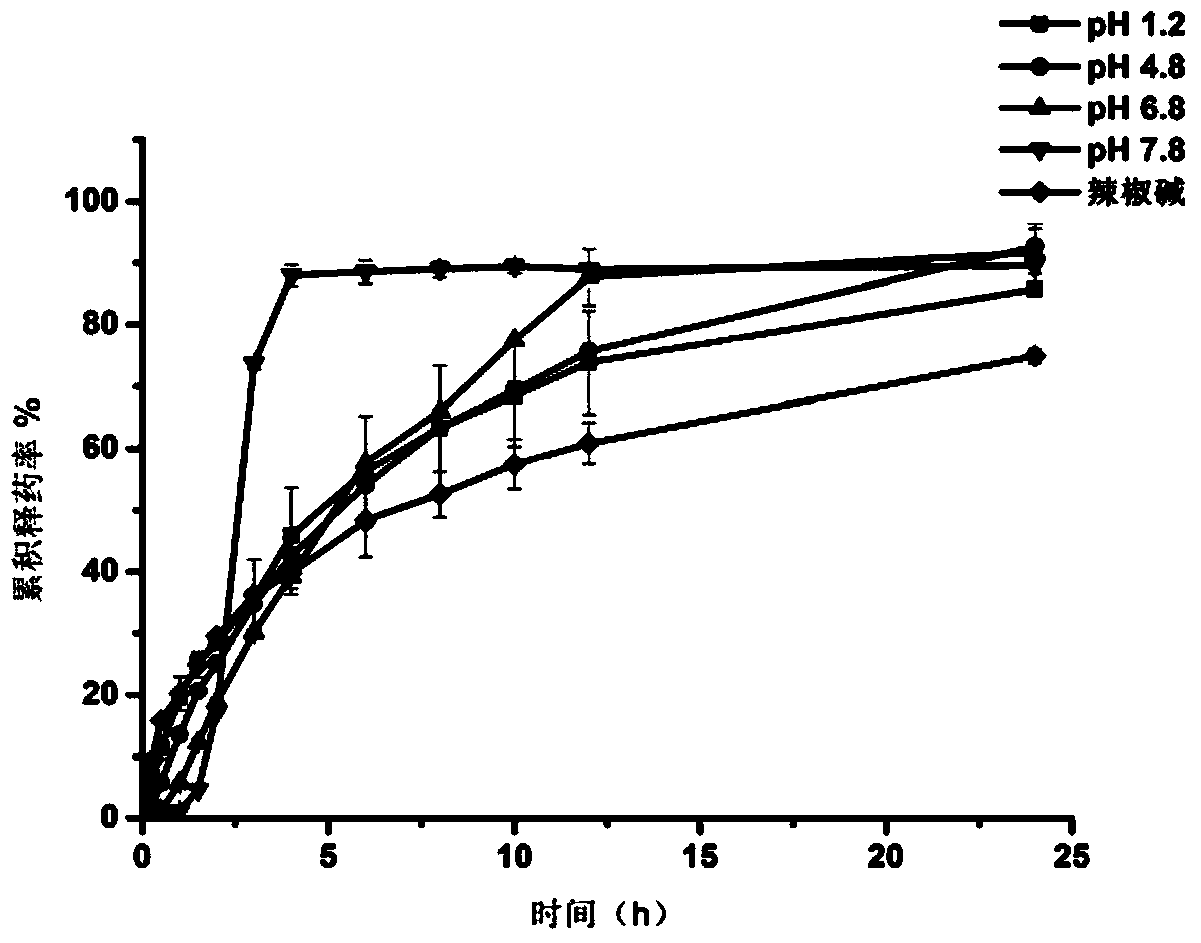

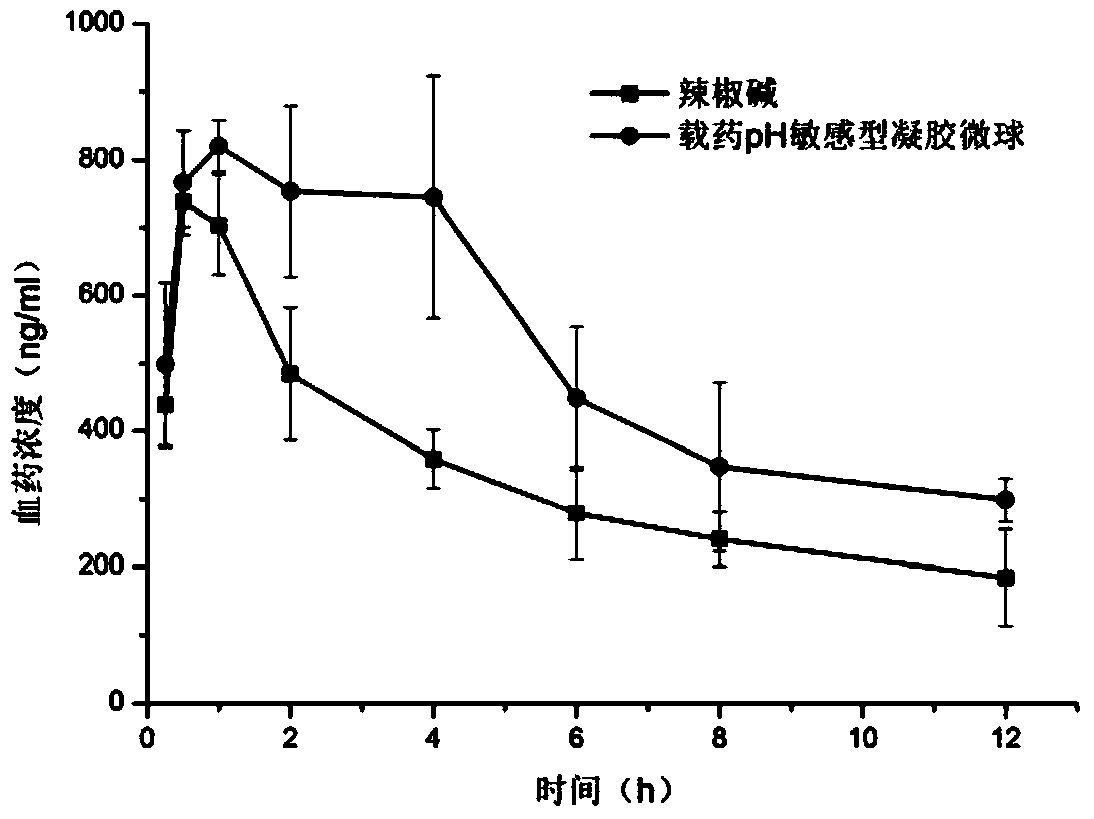

[0028] Embodiment 1, pH-sensitive gel microsphere loaded with capsaicin

[0029] (1) Accurately weigh 60mg of capsaicin, add 4mL mass percentage concentration of 3% sodium alginate and 2mL mass percentage concentration of 3% carboxymethyl chitosan mixed solution, at 60 ° C Make the capsaicin melt into the oil phase, vortex and homogenize to obtain the mixed liquid;

[0030] (2) The liquid is dripped into the CaCl with a mass percentage concentration of 3% by a constant flow pump at a certain speed 2 In the solution, at (37.0±0.5)°C, after magnetically stirring at a speed of 400rpm for 30min, the microspheres were collected, washed with distilled water several times, and vacuum-dried to constant weight to obtain the pH-sensitive gel microspheres loaded with capsaicin. ball.

Embodiment 2

[0031] Embodiment 2, pH sensitive gel microsphere loaded with capsaicin

[0032] (1) Accurately weigh 120mg of capsaicin, join 36mL mass percentage concentration as 1% sodium alginate and 6mL mass percentage concentration as the mixed solution of 3% carboxymethyl chitosan, at 60 ℃ Make the capsaicin melt into the oil phase, vortex and homogenize to obtain the mixed liquid;

[0033] (2) The liquid is dripped into the CaCl with a mass percentage concentration of 1% by a constant flow pump at a certain speed 2 In the solution, at (37.0±0.5)°C, after magnetically stirring at a speed of 400rpm for 30min, the microspheres were collected, washed with distilled water several times, and vacuum-dried to constant weight to obtain the pH-sensitive gel microspheres loaded with capsaicin. ball.

Embodiment 3

[0034] Example 3, pH-sensitive gel microspheres loaded with capsaicin

[0035] (1) Accurately weigh 60 mg of capsaicin, add 6 mL of 5% sodium alginate and 6 mL of 3% carboxymethyl chitosan in mass percent concentration, at 60 ° C Capsaicin is melted into an oil phase, vortexed and homogenized to obtain a mixed liquid,

[0036] (2) Make the liquid drip into CaCl with a mass percentage concentration of 10% at a certain speed through a constant flow pump 2 In the solution, at (37.0±0.5)°C, after magnetically stirring at a speed of 400rpm for 30min, the microspheres were collected, washed with distilled water several times, and vacuum-dried to constant weight to obtain the pH-sensitive gel microspheres loaded with capsaicin. ball.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com