Immobilized membrane for synchronously enriching phosphor and ferrum and preparation method thereof

A production method and technology for fixing membranes, applied in chemical instruments and methods, preparation of samples for testing, and other chemical processes, etc., can solve problems such as failure to achieve simultaneous fixation and mutual interference, and achieve stable shape and high enrichment capacity. , the effect of production process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

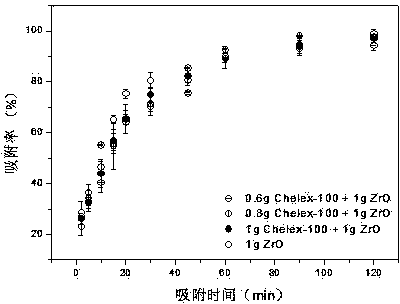

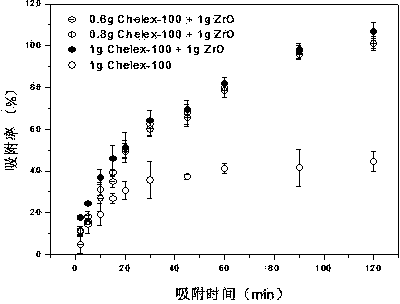

[0029] A fixed membrane for simultaneously enriching phosphorus and iron, the preparation method of which is as follows:

[0030] Use 25% ammonia water to adjust the pH of the 0.1M zirconium oxychloride aqueous solution to reach and stabilize at 7.0±0.2. The resulting precipitate is washed with deionized water until there is no chloride ion. After the precipitate is centrifuged to remove the supernatant, it is dried with a hair dryer to its The moisture content is 50±5%, and then ground into powder with a mortar to obtain hydrated zirconium hydroxide powder with a moisture content of 50±5%.

[0031] Mix 1g of hydrated zirconium hydroxide powder with a moisture content of 50±5% and 5mL of 30% polyacrylamide aqueous solution in a mortar, grind for 10min, transfer to a 10ml centrifuge tube, add 1g of Chelex-100 cation exchange resin and mix evenly to obtain the product Then add 16 μL of 10% (wt) ammonium persulfate and 8 μL TEMED to the film-forming solution, mix quickly and slow...

Embodiment 2

[0035] A fixed membrane for simultaneously enriching phosphorus and iron, the preparation method of which is as follows:

[0036] Hydrated zirconium hydroxide powder with a moisture content of 50 ± 5% was prepared according to the method of Example 1.

[0037] Mix 1g of hydrated zirconium hydroxide powder with a moisture content of 50±5% and 5mL of 30% polyacrylamide aqueous solution in a mortar, grind for 10min, transfer to a 10ml centrifuge tube, add 0.8g of Chelex-100 cation exchange resin and mix evenly to obtain Film-forming solution, then add 16 μL 10% (wt) ammonium persulfate and 8 μL TEMED to the film-forming solution, mix quickly and slowly pour it into two glass plates sandwiched by U-shaped plastic sheets of 0.4mm and uniform thickness In the gap of the formed mold; after the air bubbles are exhausted, the glass plate is placed horizontally at a low temperature of 2-4 °C for half an hour, so that the hydrated zirconium hydroxide and Chelex-100 particles can settle f...

Embodiment 3

[0040] A fixed membrane for simultaneously enriching phosphorus and iron, the preparation method of which is as follows:

[0041] Hydrated zirconium hydroxide powder with a moisture content of 55% was prepared according to the method of Example 1.

[0042] Mix 1g of hydrated zirconium hydroxide powder with a moisture content of 50±5% and 5mL of 30% polyacrylamide aqueous solution in a mortar, grind for 10min, transfer to a 10ml centrifuge tube, add 0.6g of Chelex-100 cation exchange resin and mix evenly to obtain Film-forming solution, then add 16 μL 10% (wt) ammonium persulfate and 8 μL TEMED to the film-forming solution, mix quickly and slowly pour it into two glass plates sandwiched by U-shaped plastic sheets of 0.4mm and uniform thickness In the gap of the formed mold; after the air bubbles are exhausted, the glass plate is placed horizontally at a low temperature of 2-4 °C for half an hour, so that the hydrated zirconium hydroxide and Chelex-100 particles can settle freel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com