Device for preparing trichlorosilane

A technology of trichlorosilane and silicon tetrachloride, applied in the directions of halogenated silanes and halogenated silicon compounds, etc., can solve the problems of low boiling point of dichlorodihydrosilicon, technology blockade, immature technology, etc., so as to improve the utilization rate of raw materials , to solve the effect of enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

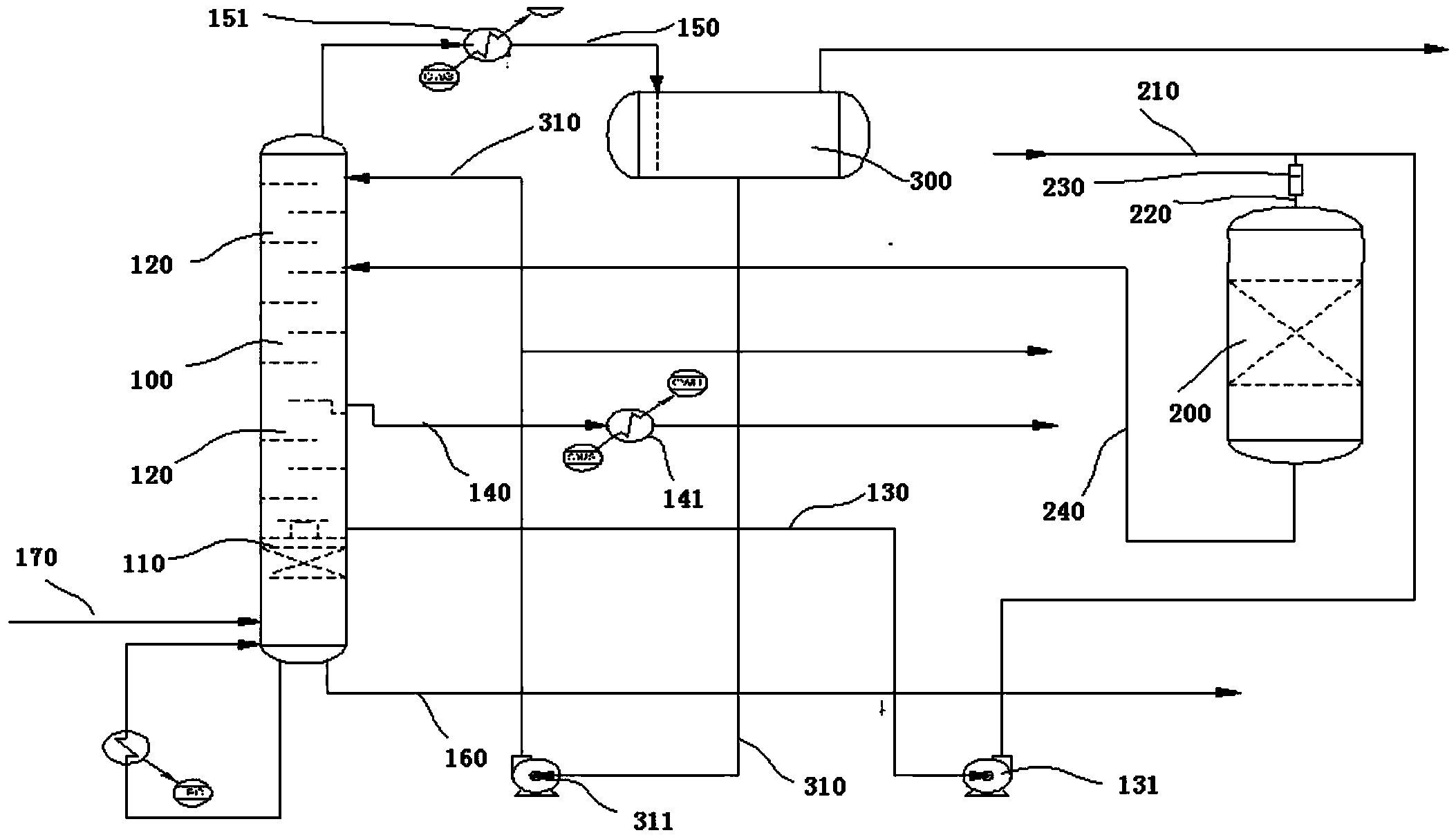

[0026] refer to figure 1 , a device for preparing trichlorosilane, which converts dichlorodihydrosilane and silicon tetrachloride, the by-products in the production process of the improved Siemens method, into trichlorosilane.

[0027] After removing impurities in a rectifying tower, silicon tetrachloride reacts with a small amount of dichlorodihydrosilane in a solidified bed reactor equipped with a basic resin catalyst at a certain bed height to produce trichlorosilane and excess Silicon tetrachloride, enters the rectification tower containing the chimney tray, removes a small amount of silane and light component trace impurities from the top of the rectification tower, and the upper side of the rectification tower is discharged to other rectif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com