Microwave photocatalytic fluidized bed waste water treatment device and treatment method

A wastewater treatment and fluidized bed technology, applied in the direction of light water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of low utilization rate of light energy and high treatment cost, and improve absorption and utilization rate, inhibition of adsorption, and improvement of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

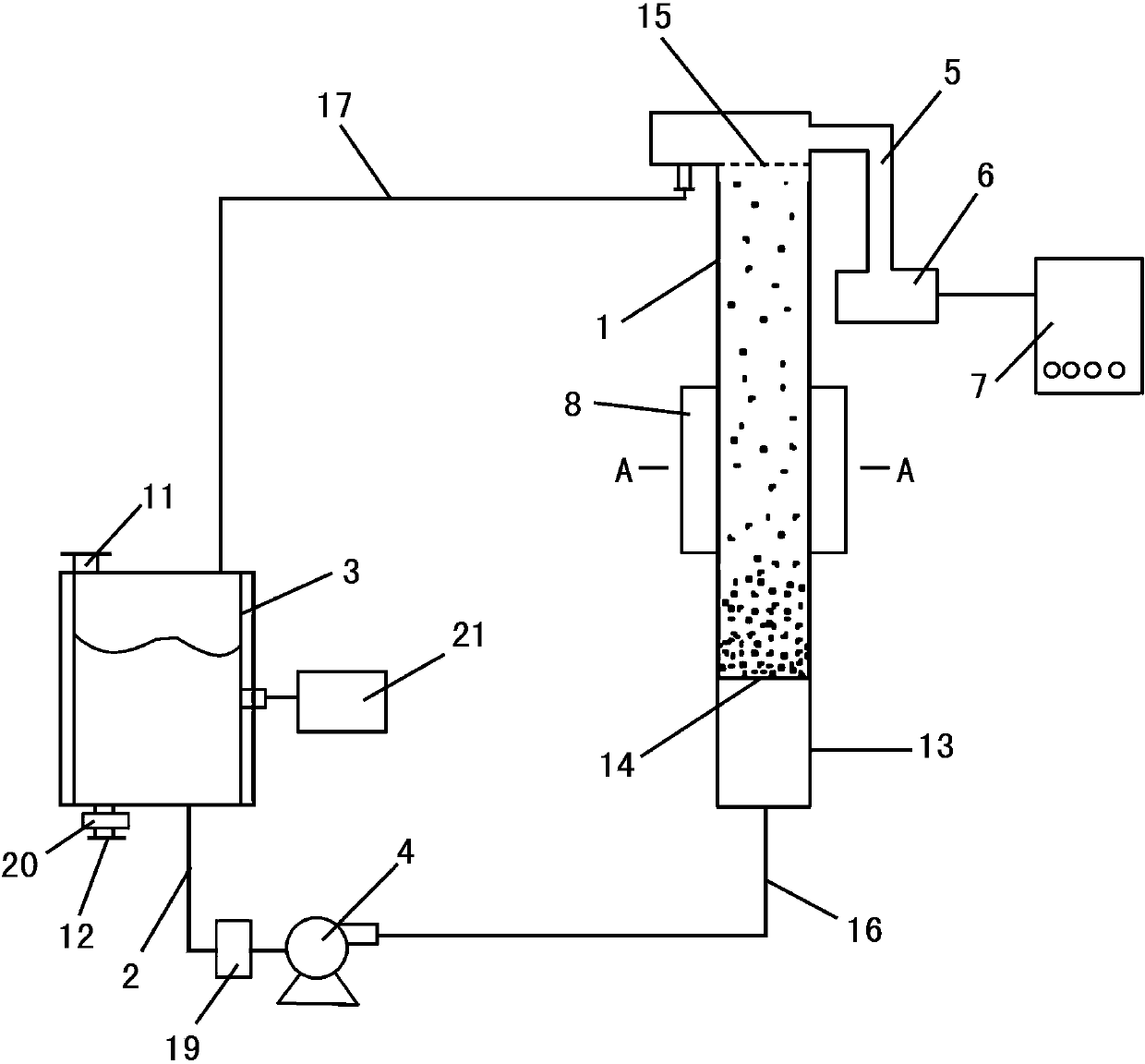

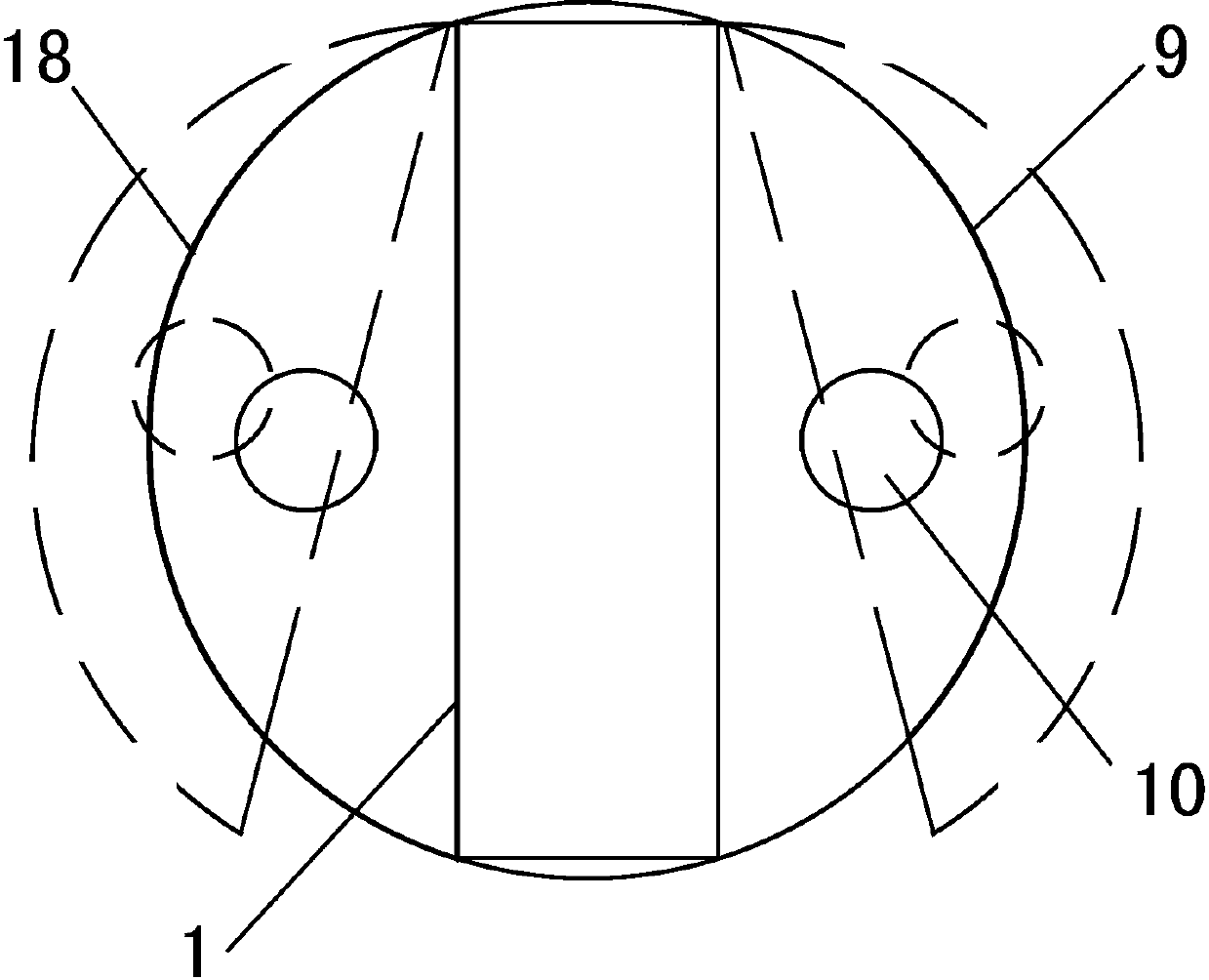

[0031] Embodiment 1, with reference to figure 1 with figure 2 , a microwave photocatalytic fluidized bed wastewater treatment device described in this specific embodiment, comprising a fluidized bed 1, a circulating water pipe 2, a buffer reflux tank 3, a diaphragm pump 4, a microwave conduit 5, a magnetron 6, and a microwave tube A power supply 7 and a photocatalytic reaction device 8, the fluidized bed 1 is connected to the buffer reflux tank 3 through the circulating water pipe 2, and a diaphragm pump 4 is arranged on the downstream of the circulating water pipe 2 between the buffer reflux tank 3 and the fluidized bed 1, and the fluidized bed 1 A microwave conduit 5 is arranged on the top side, and the microwave conduit 5 communicates with the magnetron 6. The magnetron 6 is electrically connected with the microwave tube power supply 7. A photocatalytic reaction device 8 is arranged outside the fluidized bed 1. The photocatalytic reaction device 8 includes The outer cover...

Embodiment 2

[0043] Embodiment 2, with reference to figure 1 and figure 2 , the wastewater treatment method of a microwave photocatalytic fluidized bed wastewater treatment device described in this specific embodiment, prepare 60 mg / L alizarin green simulated printing and dyeing wastewater, adjust the pH value to 5.0, and the wastewater enters the buffer reflux tank 3 through the diaphragm The pump 4 enters the fluidized bed 1 at a flow rate of 1.5 L / min, the amount of photocatalyst added is 1.0 g / L, and the water flow circulates from bottom to top. Turn on the microwave power 1kW of the magnetron 6, turn on the ultraviolet lamp 10, the waste water is subjected to the joint action of microwave, ultraviolet-visible light and photocatalyst, the temperature of the waste water is controlled at 40°C, and the concentration of the waste water is tested by the water quality online detector 21 every 5 minutes. When the concentration of the green simulated printing and dyeing wastewater is less th...

Embodiment 3

[0044] Embodiment 3, with reference to figure 1 and figure 2 , the wastewater treatment method of a microwave photocatalytic fluidized bed wastewater treatment device described in this specific embodiment, prepare 150mg / L phenol wastewater, adjust the pH value to 7.0, the chemical oxygen demand is 380mg / L, and the wastewater enters the buffer The reflux tank 3 enters the fluidized bed 1 through the diaphragm pump 4 at a flow rate of 1.5 L / min, the amount of photocatalyst added is 1.5 g / L, and the water flow circulates from bottom to top. Turn on the microwave power 2kW of the magnetron 6, turn on the ultraviolet lamp 10, the wastewater is subjected to the joint action of microwave, ultraviolet-visible light and photocatalyst, control the temperature of the wastewater at 50°C, and test the concentration of the wastewater by the water quality online detector 21 every 5 minutes, when the phenol wastewater When the concentration is less than 12 mg / L, the removal rate reaches 92%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com