Preparation method of high strength superhydrophobic coating

A super-hydrophobic coating and strength technology, applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problem of not launching products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

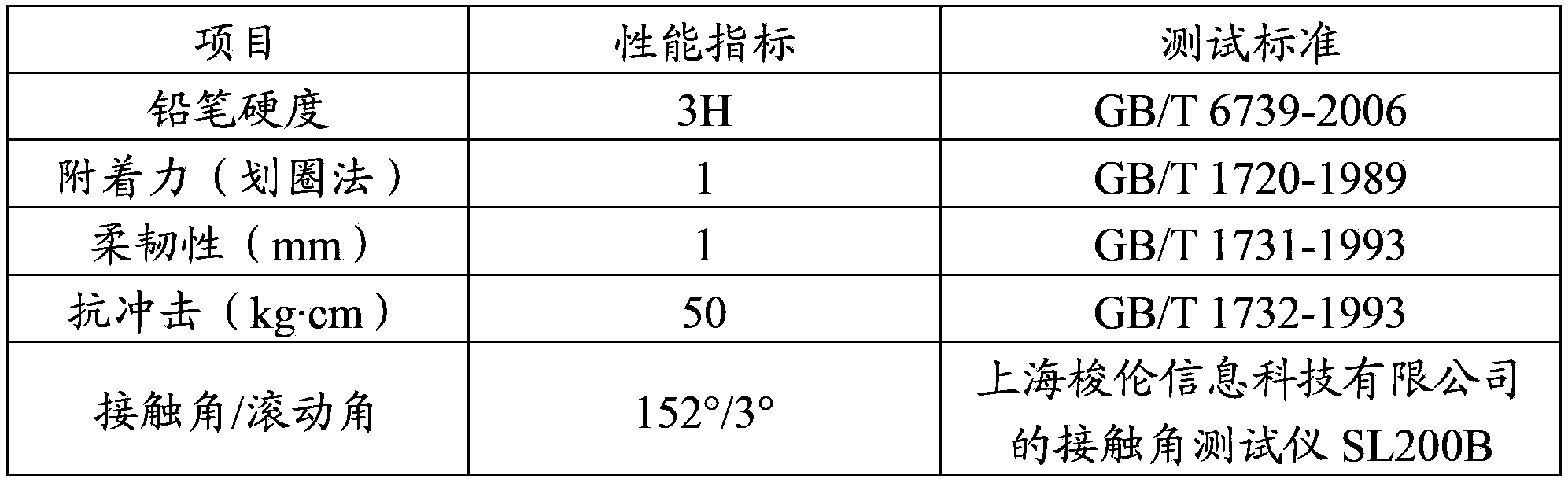

Embodiment 1

[0017] Add 5g of silica nanoparticles in a single-necked flask with a particle size of 30nm, 0.48g of silane coupling agent tetraethoxysilane, 11.2g of fluorocarbon resin containing low surface energy functional groups FY- F534, 0.3g of silane coupling agent dodecylsilane and 5.2g of fluororesin CC2-2 of Jiaxing Kairui Company are dispersed in 75.17g of solvent butyl acetate. The solvent is a conventional single solvent or a mixed solvent, and butyl acetate is selected in this embodiment. Add 0.05g catalyst dibutyltin dilaurate, stir at room temperature of 25°C for 4 hours, modify the surface of nanoparticles with low surface energy functional groups through condensation reaction, and obtain superhydrophobic silica nanoparticle sol.

[0018] Take 10g of modified nanoparticle sol and 2.89g of acrylic resin A-851 of Lihua Group containing hydroxyl groups and stir evenly at 30°C, mix 0.77g of curing agent isocyanate Bayer N3390, and then add 0.28g of anti-settling agent BYK Compa...

Embodiment 2

[0023] Add 5g silica nanoparticles in the single-necked flask, the particle size is 30nm, 0.45g silane coupling agent methyltriethoxysilane, 12.84g fluororesin CC1-1 of Jiaxing Kairui Company containing low surface energy functional groups, 5.76g of Sinochem Taicang's fluororesin containing low surface functional groups was dispersed in 75g of solvent, the solvent was a conventional single solvent or mixed solvent, the mixture of butyl acetate and xylene was used in this example, and 0.05g of catalyst dibutyl was added base tin dilaurate, stirred at room temperature of 25°C for 4 hours, and modified low surface energy functional groups on the surface of nanoparticles by condensation reaction to obtain superhydrophobic silica sol.

[0024] Add 5.07g of micron-sized clay particles with a particle size of 1-2um in a single-necked flask, 12.5g of fluororesin CC1-1 from Jiaxing Kairui Company, 5.6g of fluororesin containing Sinochem Taicang dispersed in 75g of butyl acetate and In ...

Embodiment 3

[0030] Add 5g of silica nanoparticles in a single-necked flask, particle size is 30nm, 0.5g of silane coupling agent tetraethoxysilane, 12g of fluorocarbon resin CC1-1 of Jiaxing Kairui Company containing low surface energy functional groups, 0.3g of silane coupling agent dodecylsilane and 5.5g of fluorocarbon resin CC2-2 from Jiaxing Kairui Company were dispersed in 75.17g of solvent. The solvent is a conventional single solvent or a mixed solvent, and butyl acetate is selected in this embodiment. Add 0.05g catalyst dibutyltin dilaurate, stir at room temperature of 25°C for 4 hours, modify the surface of nanoparticles with low surface energy functional groups through condensation reaction, and obtain superhydrophobic silica nanoparticle sol.

[0031] Take 10g of the above-mentioned silica sol and 2.9g of saturated polyester resin 327C containing Miki Group and stir evenly at 30°C, mix with 0.75g of curing agent Miki Group’s amino resin 5717, and then add 0.28 g of BYK’s anti-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Static contact angle | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com