Chemical adsorption refrigeration system driven by taking engine tail gas as energy

A chemical adsorption and refrigeration system technology, which is applied to the operation mode of the machine, refrigerator, refrigeration and liquefaction, etc., can solve the problems of air leakage and water leakage, deformation and cracking of the inner wall of the generator, and blockage of the flue pipe, so as to avoid spraying The effects of hole blockage, improved cooling efficiency, and enhanced cooling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

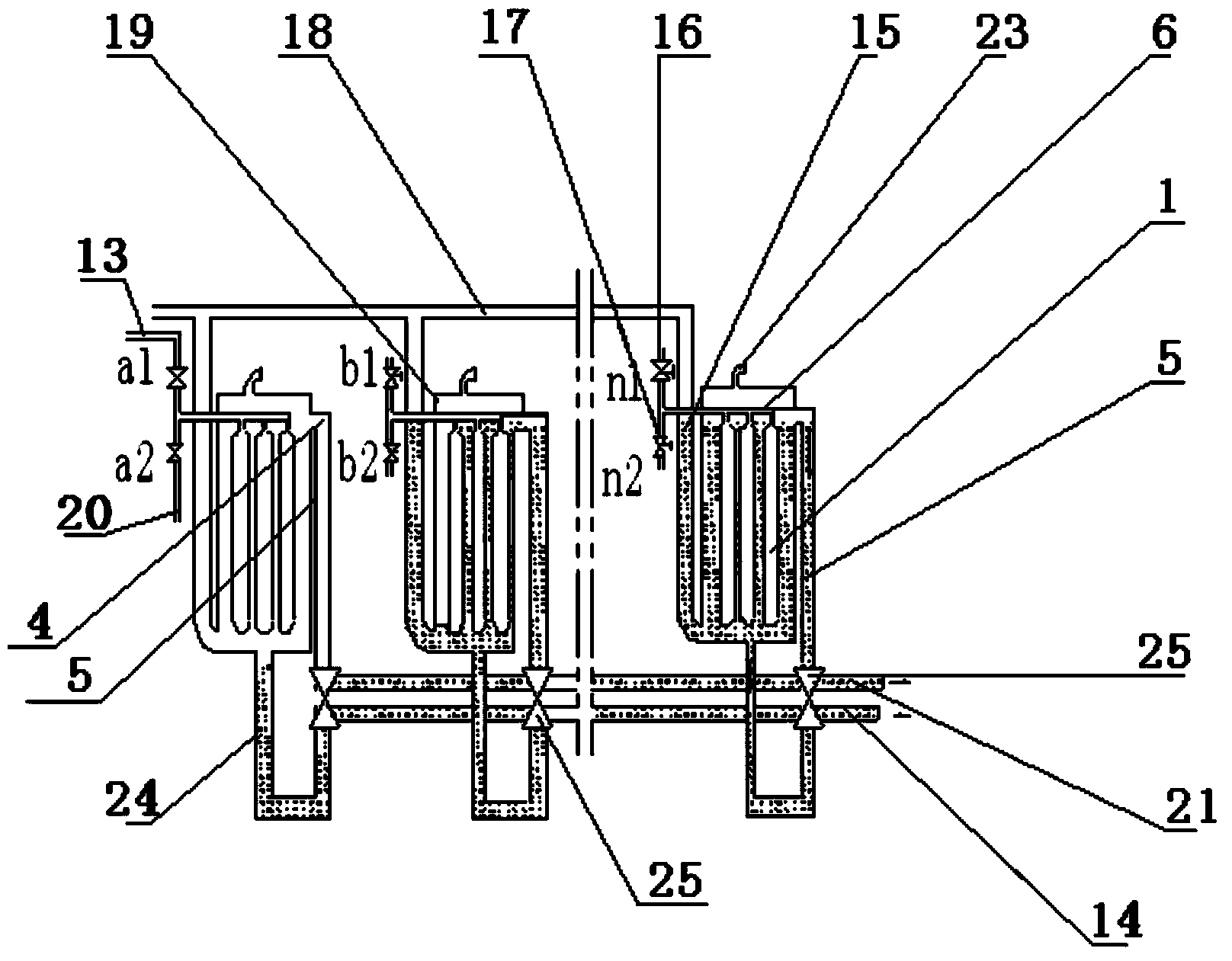

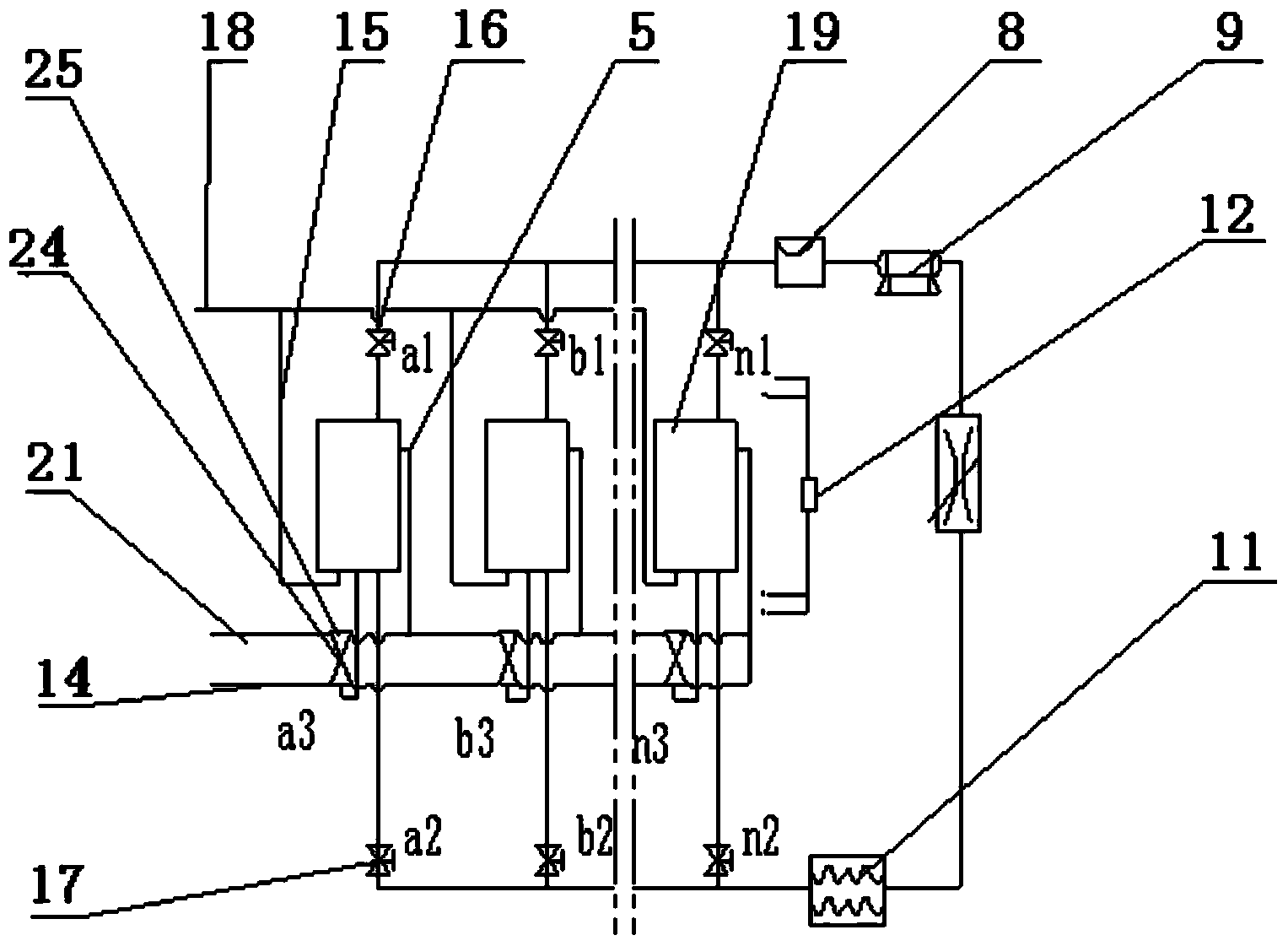

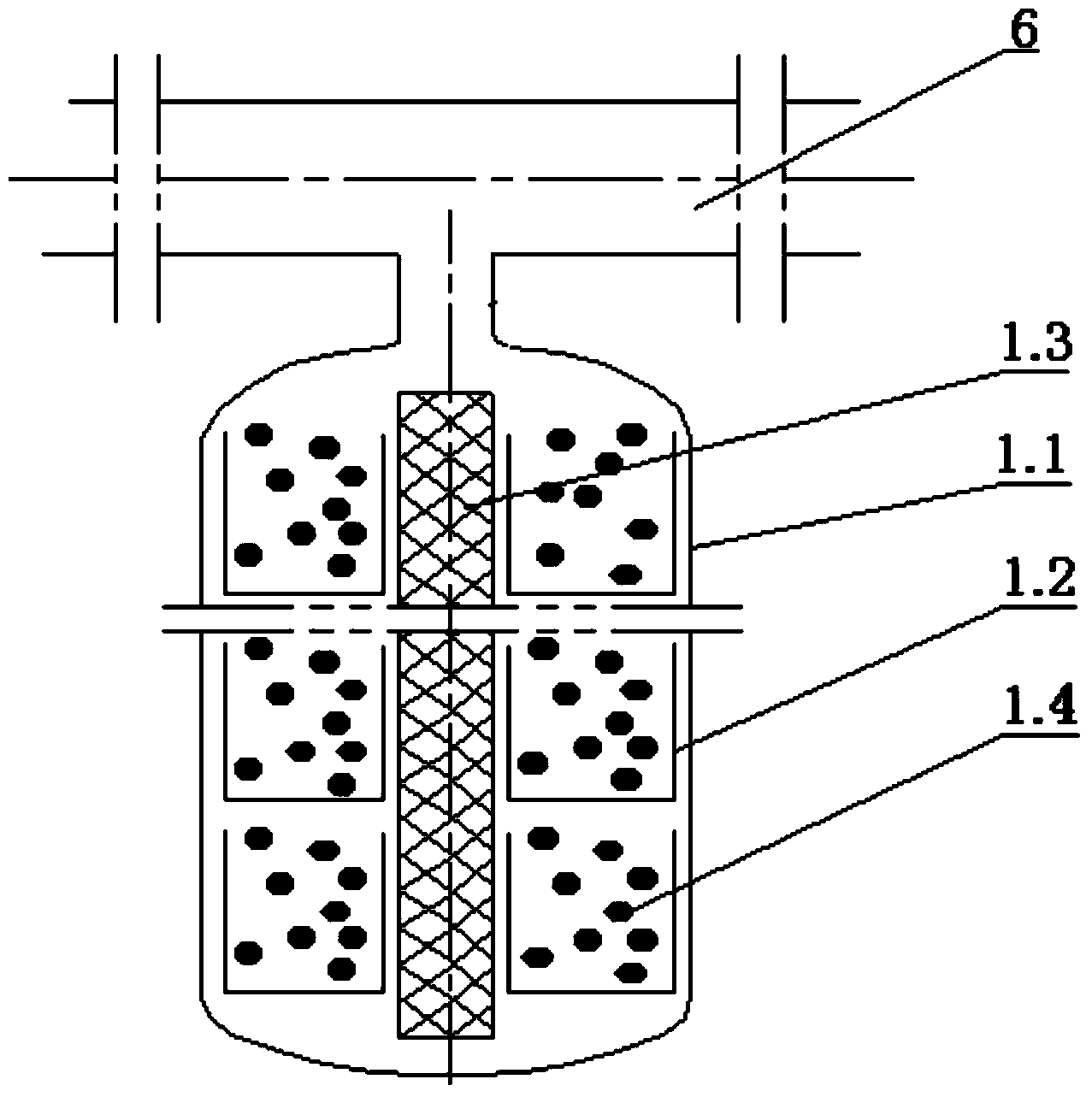

[0034] Such as figure 1 As shown, it is suitable for the prototype of the chemical adsorption refrigeration system driven by engine exhaust gas. Its adsorption bed is composed of three sets of adsorption bed assemblies 1, and each set of adsorption bed assemblies 1 includes four adsorption bed unit tubes 3 of φ70*2*500. , commonly connected to the gas main pipe 6 used for the inlet and outlet of the adsorption bed, the outside of the gas main pipe 6 is respectively connected to the one-way control valve group 16 of the deamination passage and the one-way control valve group 17 of the ammonia absorption passage; the flue gas inlet pipe 15 connects with the adsorption bed from the bottom The inner cavity is connected, the cooling water overflow pipe 5 of the adsorption bed is connected with the inner cavity of the adsorption bed from the upper side, and the U-shaped water seal pipe 24 is connected with the inner cavity of the adsorption bed from the bottom. The water level diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com