Preparation method for semiconductor nanowire orderly distributed in array mode

A technology of nanowire arrays and ordered arrays, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, nanotechnology, etc., can solve the problems of difficult preparation of nanowires and high cost, and achieve the effect of reducing power generation costs and improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

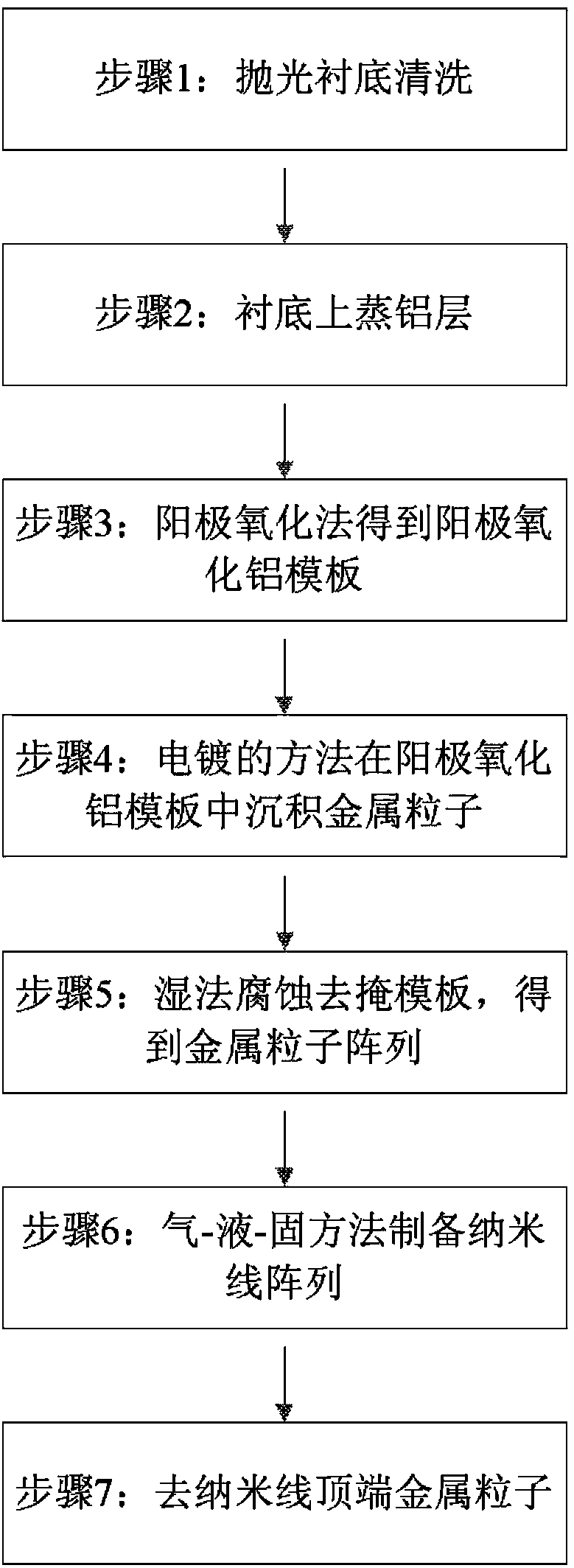

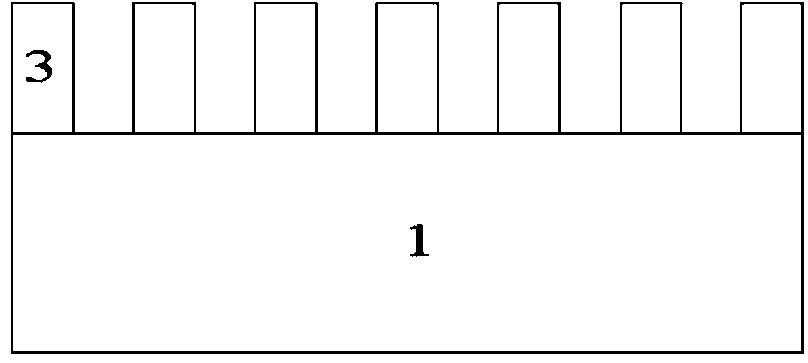

[0020] see Figure 1-Figure 7 As shown, the present invention provides a method for preparing a semiconductor nanowire ordered array distribution, comprising the following steps:

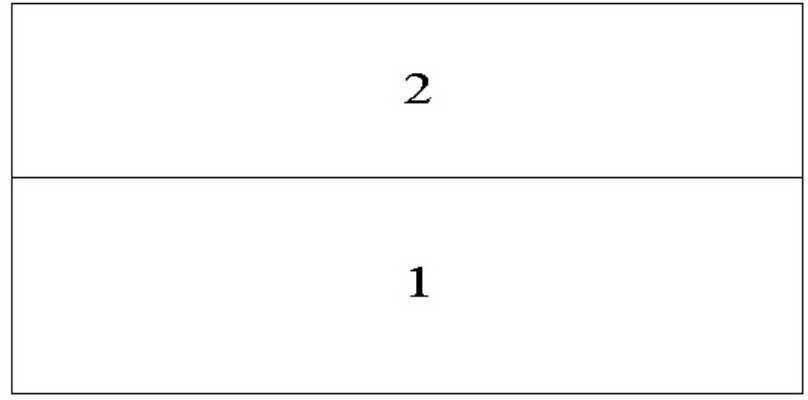

[0021] Step 1: Clean a substrate 1 to obtain a polished substrate from which organic substances, heavy metals, and oxide layers have been removed. The material of the substrate 1 is silicon. Clean the silicon wafer of the substrate 1 in strict accordance with the degreasing and cleaning of the silicon wafer of the substrate 1. The steps of removing heavy metals and oxide layers are cleaned, and then the silicon wafer of the substrate 1 is blown dry with a nitrogen gun, and put into the sample box;

[0022] Step 2: An aluminum layer 2 with an adjustable thickness is vapor-deposited on the substrate 1, and the aluminum layer 2 is grown by thermal evaporation and magnetron sputtering. Choose the thickness according to your own needs, and vapor-deposit a layer of aluminum layer 2 with an adjustable thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com