A flour improver and its application

A flour improver and edible fungus technology, applied in the field of flour improver, flour improver containing active bacillus and edible fungus, can solve the problems of skin loss, bread quality decline, shelf life shortening, etc., to achieve skin gloss, Longer shelf life and improved softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

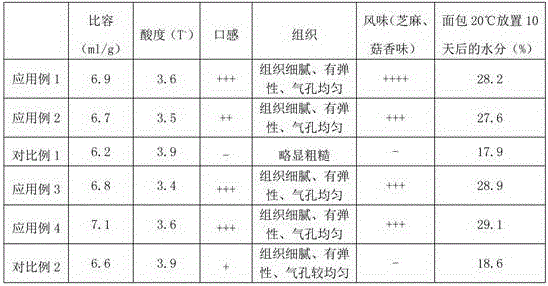

Examples

Embodiment 1

[0033] Soy protein isolate, wheat bran powder, and konjac extract that meet food-grade requirements are passed through an 80-mesh sieve.

[0034] Get soybean protein isolate to prepare soybean protein isolate culture, the method is as follows:

[0035] a. Using a conventional method, use wort juice with 8 degrees Baume as a medium, and culture Bacillus subtilis liquid strains for 24 hours at 37° C. and 200 r / min.

[0036] b. Spray evenly the liquid strain cultured in a on the soybean protein isolate, wherein, material: bacterial liquid = 1:2.3, mix well, and culture at 37°C for 36 hours.

[0037] c. Dry the soy protein isolate cultured in b in a hot air drying oven at 60°C until the water content is below 10%, and then pulverize to obtain the soy protein isolate culture.

[0038] The bacterial content in the culture is ≥2.1×10 10 cfu / g.

[0039] Get wheat bran powder and prepare wheat bran culture, the method is as follows:

[0040] a. Using the conventional method, use th...

Embodiment 2

[0046] Soy protein isolate, wheat bran powder, and konjac extract that meet food-grade requirements are passed through an 80-mesh sieve.

[0047] Get soybean protein isolate to prepare soybean protein isolate culture, the method is as follows:

[0048] a. Using a conventional method, use wort juice with 8 degrees Baume as the medium, and culture Bacillus natto liquid strains for 28 hours at 35° C. and 180 r / min.

[0049] b. Spray the cultured liquid bacteria in a evenly on the soybean protein isolate, wherein, material: bacteria liquid = 1:2.5, mix well, and culture at 35°C for 24 hours.

[0050] c. Dry the soy protein isolate cultivated in b in a hot air drying oven at 70°C until the water content is below 10%, and then pulverize to obtain the isolated soy protein culture.

[0051] The bacterial content in the culture is ≥2.0×10 10 cfu / g.

[0052] Get wheat bran powder and prepare wheat bran culture, the method is as follows:

[0053] a. Adopt conventional method, take wo...

Embodiment 3

[0059] Soy protein isolate, wheat bran powder, and konjac extract that meet food-grade requirements are passed through an 80-mesh sieve.

[0060] Get soybean protein isolate to prepare soybean protein isolate culture, the method is as follows:

[0061] a. Using a conventional method, use wort juice of 8 degrees Baume as a culture medium, and culture Bacillus subtilis liquid strains for 26 hours at 36° C. and 180 r / min in squeeze bottles.

[0062] b. Spray evenly the liquid strain cultured in a on the soybean protein isolate, wherein, material: bacteria liquid = 1:2.4, mix well, and culture at 36°C for 30 hours.

[0063] c. Dry the soy protein isolate cultured in b in a hot air drying oven at 65°C until the water content is below 10%, and then crush to obtain the soy protein isolate culture.

[0064] The bacterial content in the culture is ≥1.8×10 10 cfu / g.

[0065] Get wheat bran powder and prepare wheat bran culture, the method is as follows:

[0066] a. Adopt conventiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com