Hard alloy tool mold manufacturing method

A technology of hard alloy and production method, which is applied in the field of production of hard alloy products, can solve the problems of unfavorable performance indicators such as porosity and strength, time-consuming and consumable materials, and difficulty in one-time molding of molds, etc., so as to improve the internal quality and service life, solve the high production cost, and improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

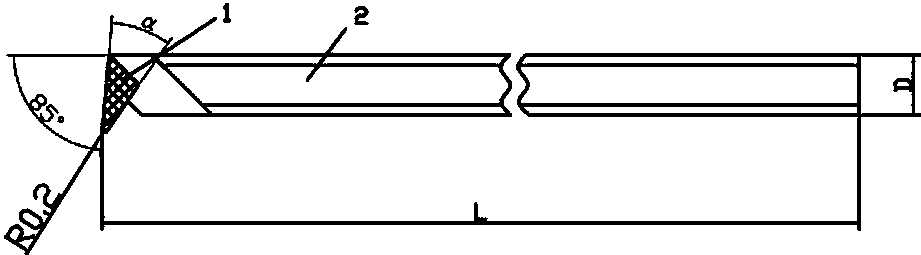

[0028] Embodiment one : Making pipe drawing die of material YG6 φ34*21*d15, powder metallurgy die of material YG8 φ34*30*d20 and nut die of material YG20C φ24*20*d15×5 O Three kinds of carbide tool blank products.

[0029] 1. The specific operation steps for making the φ34*21*d15 carbide drawing die blank product of material YG6 are as follows:

[0030] (1) Calculate the processing size before sintering: Calculate the processing size of the product before sintering with the shrinkage coefficient of 1.225 as φ41.65×25.75×d 18.38.

[0031] (2) Compression molding of simple blanks: Select a pressing mold with an inner hole of 41.65mm and a mandrel of 18.38mm, weigh 235.3g of YG6 mixture (containing 2% paraffin), and press out a blank with a height of 25.8mm.

[0032] (3) Modification processing: Clamp the PCD bore cutter on the tool holder of the CNC lathe, write the program and start the machine to process the simple blank.

[0033] (4) Inspection: After the lathe is running...

Embodiment 2

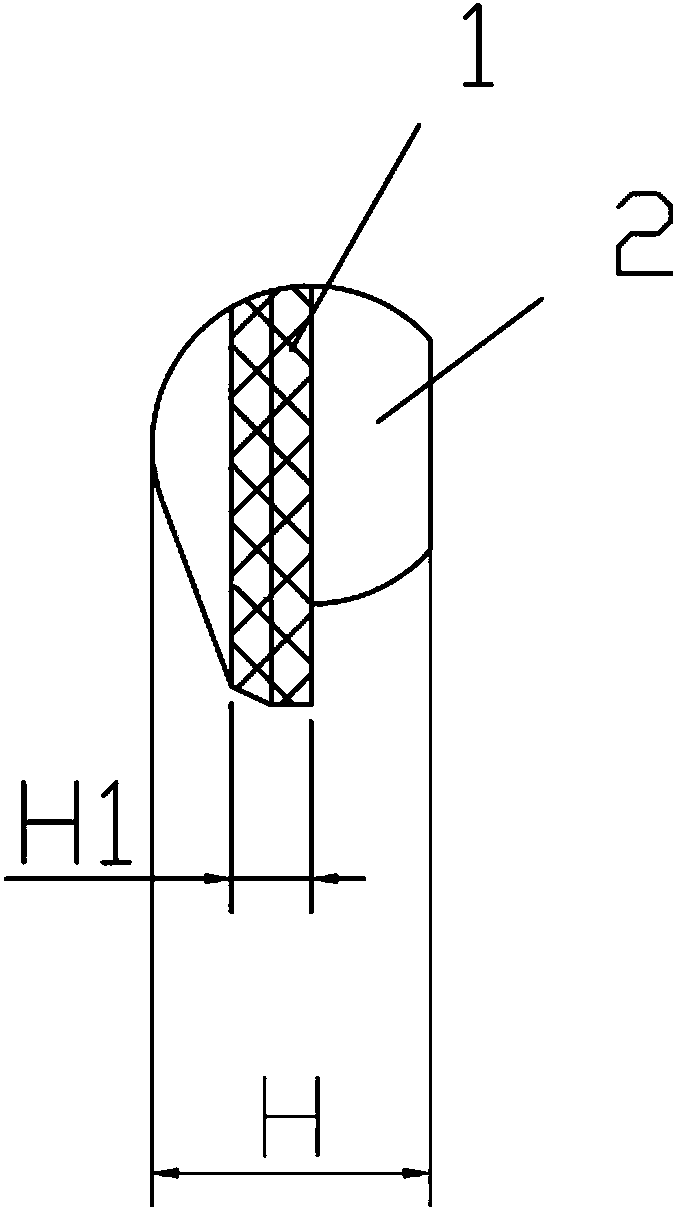

[0047] Embodiment two : Mandrel φ22 / 25*32*d0 for metal pipe drawing of material YG6X, φ20 / 25*35*d0 for metal pipe drawing of material YG6X and YG15 solid round rod φ25×45.

[0048] 1. The specific operation steps for making φ22 / 25*32*d0 metal pipe stretching core blank products with material YG6X are as follows:

[0049] (1) Calculate the processing size before sintering: calculate the processing size before sintering φ27.72 / 31.50*40.32 with the shrinkage coefficient of 1.26.

[0050] (2) Compression molding of simple blanks: Select a pressing mold with an inner hole of 35.69mm and a mandrel of 0mm, weigh 307.7g of YG6X mixture (containing 2.0% paraffin), and press a blank with a height of 40.4mm.

[0051] (3) Modification processing: Since the height has been formed in place, only the modification processing of the outer diameter of the car is required. It is planned to use the three-jaw chuck to position and clamp the outer circle to process the large outer diameter, and ...

Embodiment 3

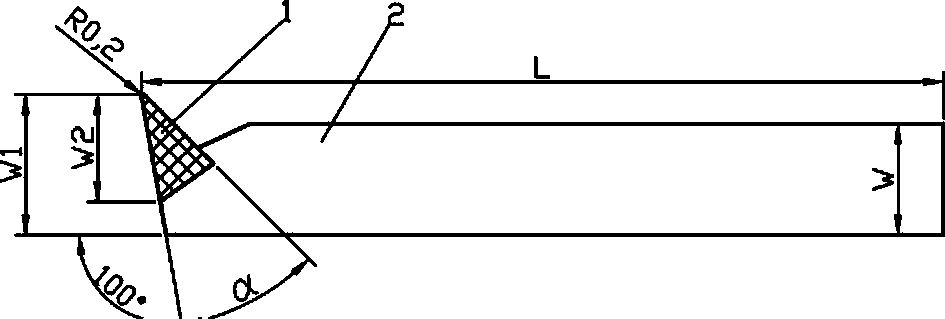

[0066] Embodiment three: Make YG10X 30.5 / 16×55 T-knife, YG10X 30.5 / 20×55 T-knife and YG10X 25.5 / 20×55 T-knife.

[0067] 1. The specific operation steps for making YG10X 30.5 / 16×55 T-knife blank products are as follows:

[0068] (1) Calculate the processing size before sintering: calculate the size before sintering with the shrinkage coefficient of 1.25 as 39.35 / 20.64×70.95.

[0069] (2) Compression molding of simple blanks: Select a solid-core pressing mold with an inner hole of 39.35 mm, weigh 676.80 grams of YG10X mixture (containing 2.5% paraffin), and press a blank with a height of 78.70 mm.

[0070] (3) Reshape processing: use the three-jaw chuck to position and clamp the outer circle for processing, first process the center head and the small outer diameter part, and then turn around to process the center head at the other end. Clamp the PCD turning tool on the lathe tool holder. According to the processing size before sintering, adjust the angle of the tool to proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com