Method and device for removing aluminum trichloride from chlorosilane

A technology of aluminum trichloride and chlorosilane, which is applied in the direction of halosilane and silicon halide compounds, can solve the problems of low efficiency, high cost, deep pollution of chlorosilane, etc., and achieve good removal effect, low cost and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

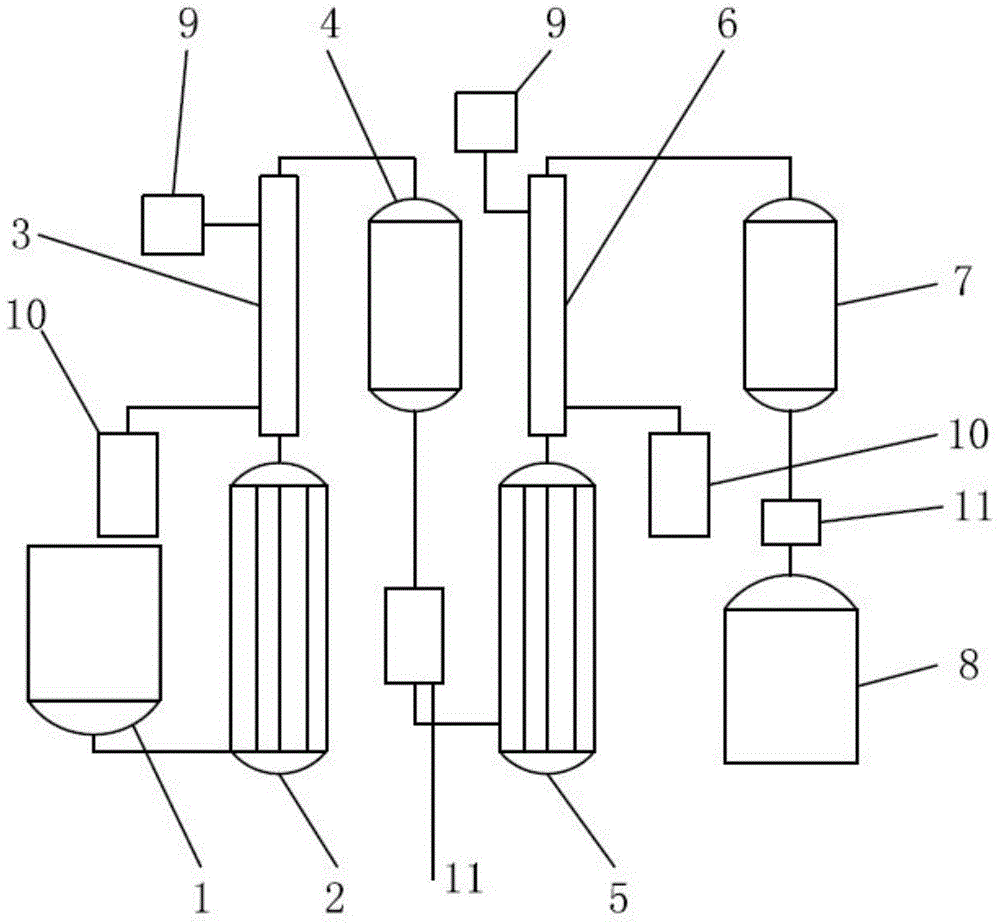

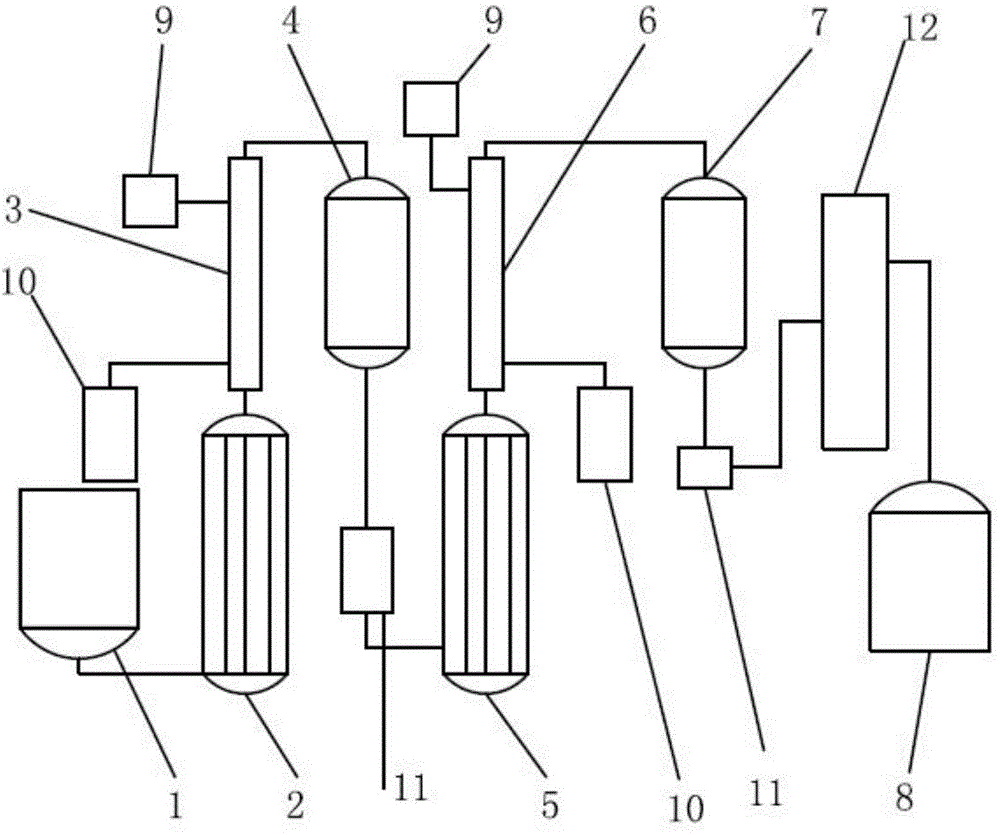

[0035] A preparation device for a method of removing aluminum trichloride from chlorosilanes, such as figure 1 As shown, the raw liquid storage tank, the first distillation tower 2, the first impurity remover 3, the buffer tank 4, the second distillation tower 5, the second impurity remover 6, the condenser 7 and the purification storage tank 8 are sequentially included. The tank is connected to the bottom of the first distillation tower 2, the top of the first distillation tower 2 is connected to the first impurity remover 3, the first impurity remover 3 is connected to the top of the buffer tank 4, and the bottom of the buffer tank 4 is connected to the second distillation tower 5, The second distillation tower 5 is connected with the top of the second impurity remover 6, the top of the second distillation tower 5 is connected with the top of the condenser 7, the condenser 7 is connected with the purification storage tank 8, the first impurity remover 3 and the second impuri...

Embodiment 2

[0042] A preparation device for a method of removing aluminum trichloride from chlorosilanes, such as figure 1 As shown, the raw liquid storage tank, the first distillation tower 2, the first impurity remover 3, the buffer tank 4, the second distillation tower 5, the second impurity remover 6, the condenser 7 and the purification storage tank 8 are sequentially included. The tank is connected to the bottom of the first distillation tower 2, the top of the first distillation tower 2 is connected to the first impurity remover 3, the first impurity remover 3 is connected to the top of the buffer tank 4, and the bottom of the buffer tank 4 is connected to the second distillation tower 5, The second distillation tower 5 is connected with the top of the second impurity remover 6, the top of the second distillation tower 5 is connected with the top of the condenser 7, the condenser 7 is connected with the purification storage tank 8, the first impurity remover 3 and the second impuri...

Embodiment 3

[0049] A preparation device for a method of removing aluminum trichloride from chlorosilanes, such as figure 1 As shown, the raw liquid storage tank, the first distillation tower 2, the first impurity remover 3, the buffer tank 4, the second distillation tower 5, the second impurity remover 6, the condenser 7 and the purification storage tank 8 are sequentially included. The tank is connected to the bottom of the first distillation tower 2, the top of the first distillation tower 2 is connected to the first impurity remover 3, the first impurity remover 3 is connected to the top of the buffer tank 4, and the bottom of the buffer tank 4 is connected to the second distillation tower 5, The second distillation tower 5 is connected with the top of the second impurity remover 6, the top of the second distillation tower 5 is connected with the top of the condenser 7, the condenser 7 is connected with the purification storage tank 8, the first impurity remover 3 and the second impuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com