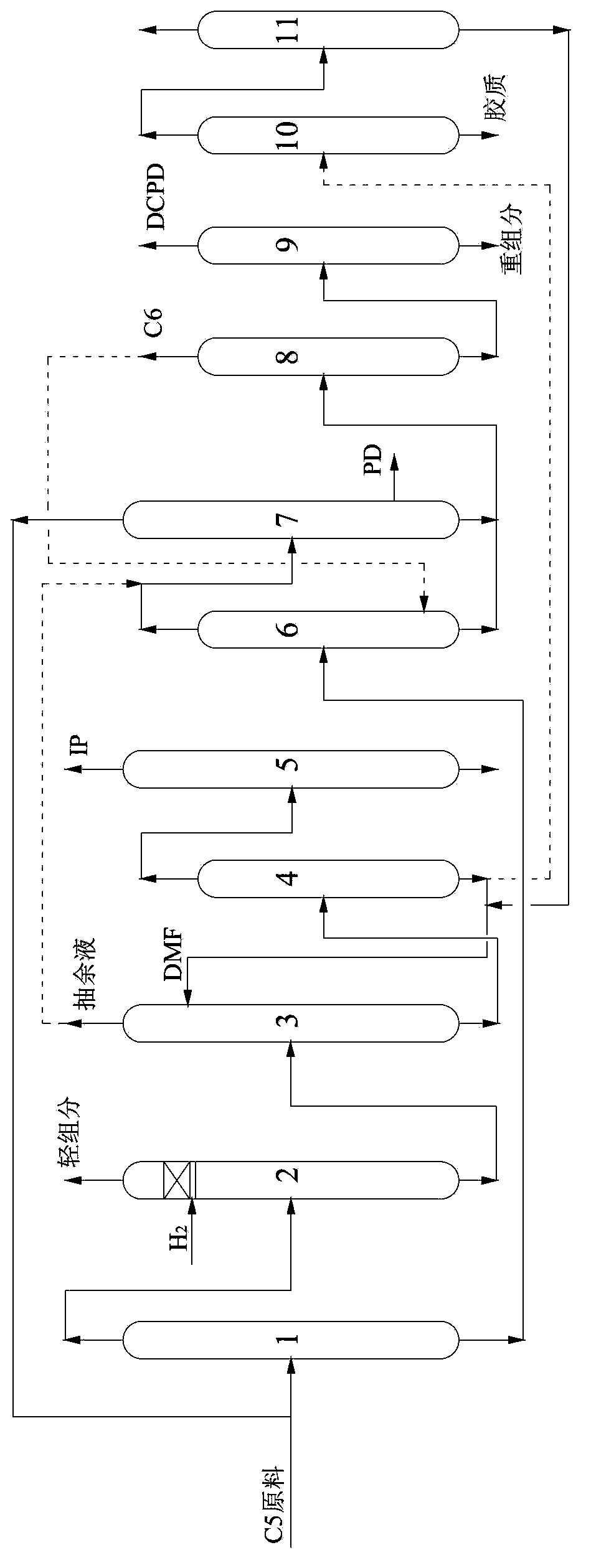

Method for separating dialkene in cracking C5 fraction

A technology for cracking carbon and pentadiene, which is used in distillation purification/separation, hydrocarbon purification/separation, chemical instruments and methods, etc., can solve the problems of complex purification methods, long process flow and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070]Using the cracked C5 fraction of a certain factory as raw material, the hydrogenation rectification separation method of the present invention is used to separate the cracked C5 fraction. The composition of the raw material and the composition of the incoming and outgoing streams of each operating device are listed in the following table.

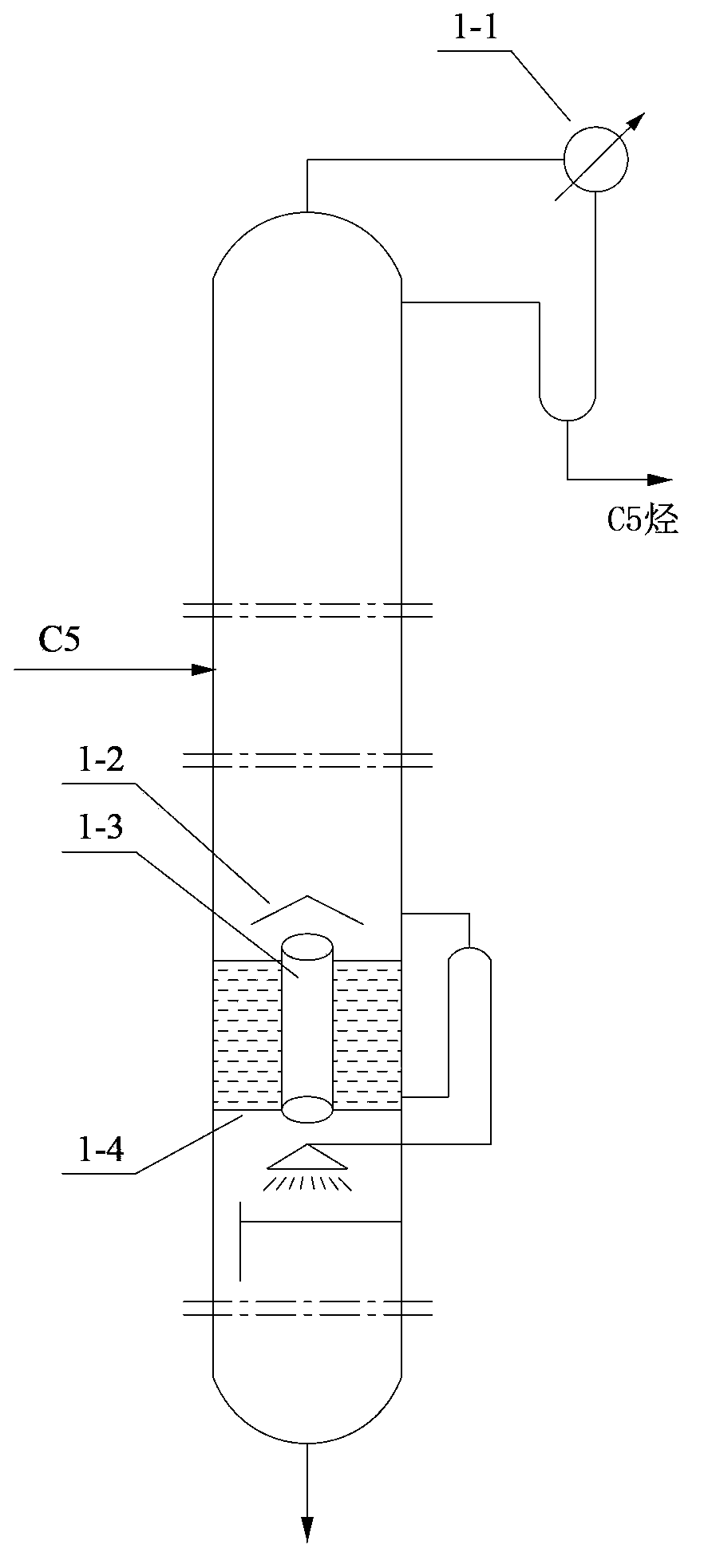

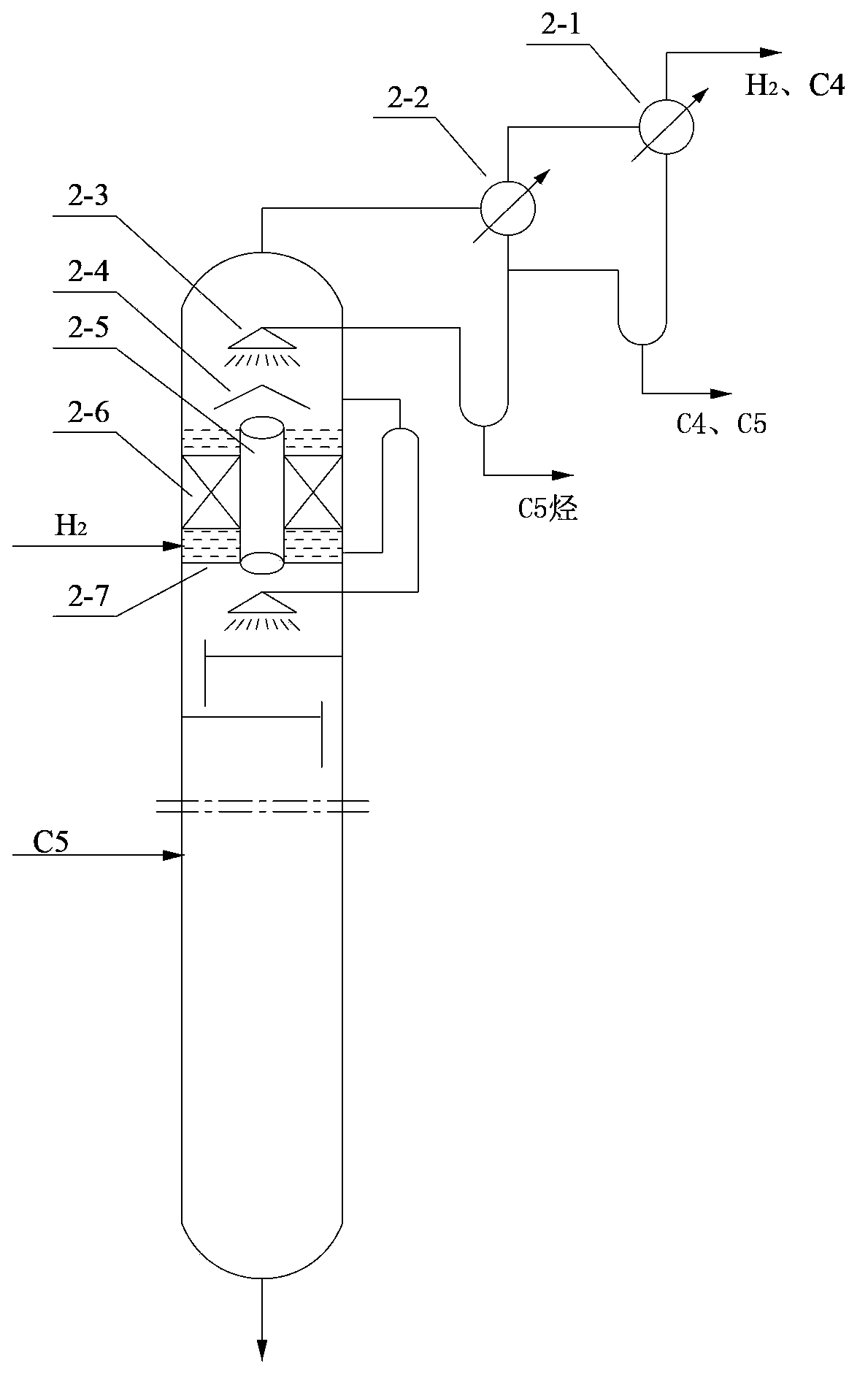

[0071] (1) Weight removal: the cracked C5 raw material enters the middle part of the weight removal reaction distillation tower 1, and the flow rate of the cracked C5 raw material is 6.3 tons / hour. The weight removal reaction distillation tower has 110 theoretical plates, and the reflux ratio is 15, and the temperature at the top of the tower is 45°C. Through the reactive distillation process, the stream containing isoprene is extracted from the top of the de-weighting reactive distillation tower 1, and the stream containing isoprene is extracted from the bottom of the de-weighting reactive distillation tower 1. The stream of alkene, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap