Method for preparing gasoline high-octane rating blending component by coking byproducts

A coking by-product and high-octane technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrogenation process, etc., can solve the problems of environmental pollution, complicated process, and increased cost

Inactive Publication Date: 2014-09-24

TAIYUAN UNIV OF TECH

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

All three have high sulfur content and poor stability. When used as fuel, they not only cause environmental pollution but also waste precious resources.

Although this method improves the added value of medium and low temperature coal tar to a certain extent, it is only suitable for the processing of medium and low temperature coal tar. will inevitably increase the cost

[0006] CN101712888B discloses "a heavy benzene hydrogenation refining process". After heavy benzene is filtered, it is mixed with hydrogen and passed through a hydrogenation device for hydrogenation refining to obtain the target product industrial naphthalene and solvent oil. This method improves the utilization of heavy benzene resources to a certain extent , but the added value of the product is still low

[0009] Comparing petroleum straight run oil and catalytic cracking oil, coking by-products such as light oil heavy fraction, dephenolized phenolic oil, and heavy benzene have the advantages of similar components, high aromatic content, low olefin content, and many high-octane components , but its composition is complex, there is a certain amount of unsaturated components, and the stability is poor; it also contains a certain amount of S, N, O heteroatom compounds, which will corrode equipment and pollute the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0053] Example 2

Embodiment 2

[0055] Example 3

Embodiment 3

[0057]

[0058] Example 4

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for preparing a gasoline high-octane rating blending component by coking byproducts. The method comprises the steps of carrying out hydrogenation reaction on coking byproducts of coal tar light oil heavy fraction, dephenolization oil and heavy benzene in a fixed bed reactor of a hydrogenation catalyst, cooling the reaction product and separating gas from liquid of the reaction product so as to obtain the product oil, separating a little benzene and heavy fraction, thereby finally obtaining the gasoline high-octane rating blending component. The method reasonably uses the byproducts which are generated in recycling and processing of coking chemical products, are small in quantity, have the similar components and are difficult to purify and separate to the greatest extent, prevents the byproducts from polluting the environment and corroding the equipment in conventional treatment and use, can obtain low-sulfur and high-aroma gasoline high-octane rating blending component, and effectively relieves the pressure on demand of gasoline products. The method for preparing the gasoline high-octane rating blending component by coking byproducts is a clean, high value-added and novel technology.

Description

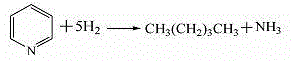

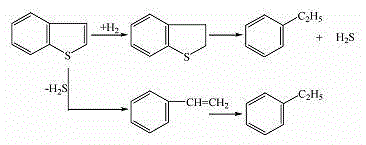

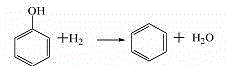

technical field [0001] The invention relates to a blending method for preparing gasoline components from coking by-products, in particular to a method for preparing high-value-added gasoline and high-octane blending components by using a hydroisomerization process. Background technique [0002] The main composition of gasoline in my country is catalytic cracking (FCC) gasoline, whose olefin content is as high as 40% to 50%, far exceeding the requirement of no more than 24% olefin in the National V standard of motor gasoline, and FCC gasoline has high sulfur, high The characteristics of olefins and low aromatics, and more importantly, hydrodesulfurization will lead to a significant decrease in the octane number which is not high. In addition, with the rapid development of my country's coal chemical industry, the output of coal tar and crude benzene in coking enterprises is also gradually increasing, and the utilization of waste generated in the recycling and processing of coki...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10G67/02

Inventor 申曙光任云朋张东峰孙瑞军石朝益范济民赵志军

Owner TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com