A kind of vehicle lubricating oil containing modified nano-diamond and preparation method thereof

A nano-diamond and automotive lubricating oil technology, which is applied in the petroleum industry, lubricating compositions, additives, etc., can solve the problems of poisonous exhaust gas conversion device catalyst, short service life of lubricating oil, and polluting the atmospheric environment, and achieve excellent adsorption properties. Chemical reactivity, life extension, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

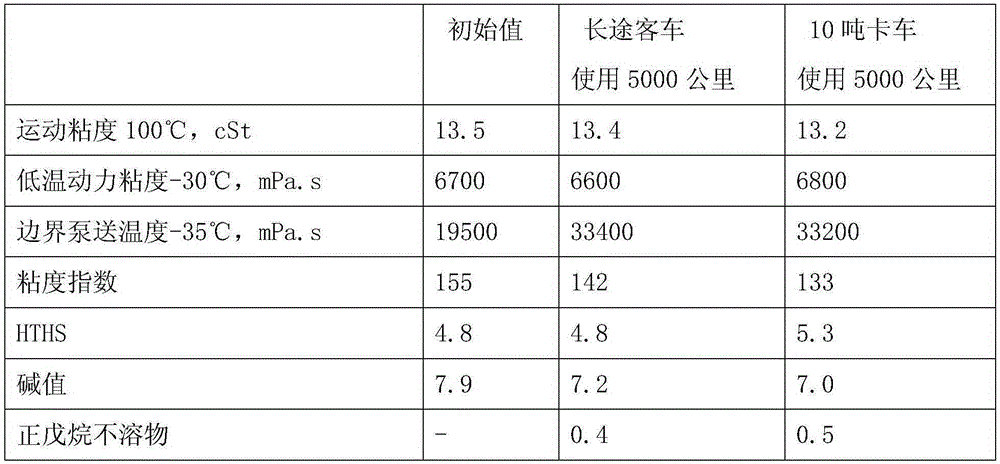

Image

Examples

Embodiment 1

[0023] A kind of vehicle lubricating oil containing modified nano-diamond, comprising the following components in parts by weight: 20 parts of modified nano-diamond, 50 parts of high-viscosity base oil, 10 parts of molybdenum dialkyl dithiophosphate, 10 parts of polyalphaolefin, 20 parts of ethylene-propylene copolymer. The modified nano-diamond is obtained by modifying CTM1 and CTM2. High-viscosity base oils are base oils with a viscosity index above 130. The particle size of the modified nano-diamond is 2nm.

[0024] A method for preparing a vehicle lubricating oil containing modified nano-diamond, comprising the following steps: adding high-viscosity base oil, organic molybdenum mixture, high-viscosity polyolefin, modified nano-diamond and viscosity index improver according to the above-mentioned parts by weight Dissolve in the kettle, and use heat conduction oil to heat up to 150°C, so that the above raw materials are completely dissolved, and continue to stir at a const...

Embodiment 2

[0026] A kind of vehicle lubricating oil containing modified nano-diamond, comprising the following components in parts by weight: 30 parts of modified nano-diamond, 80 parts of high-viscosity base oil, 20 parts of molybdenum thiophosphate, alkyl polyphenylene 20 parts of ethylene, 30 parts of ethylene-propylene copolymer. The modified nano-diamond is obtained by modifying CTM1 and CTM2. High-viscosity base oils are base oils with a viscosity index above 130. The particle size of the modified nano-diamond is 20nm.

[0027] A method for preparing a vehicle lubricating oil containing modified nano-diamond, comprising the following steps: adding high-viscosity base oil, organic molybdenum mixture, high-viscosity polyolefin, modified nano-diamond and viscosity index improver according to the above-mentioned parts by weight Dissolve in the kettle, and heat up to 160°C with heat-conducting oil, so that the above raw materials are completely dissolved, and continue to stir at a con...

Embodiment 3

[0029] A kind of vehicle lubricating oil containing modified nano-diamond, according to parts by weight, comprising the following components: 25 parts of modified nano-diamond, 65 parts of high-viscosity base oil, 15 parts of molybdenum salt of organic acid, 7 parts of polyalpha-olefin 8 parts, 8 parts of alkyl polystyrene, 25 parts of ethylene-propylene copolymer. The modified nano-diamond is obtained by modifying CTM1 and CTM2. High-viscosity base oils are base oils with a viscosity index above 130. The particle size of the modified nano-diamond is 10nm.

[0030] A method for preparing a vehicle lubricating oil containing modified nano-diamond, comprising the following steps: adding high-viscosity base oil, organic molybdenum mixture, high-viscosity polyolefin, modified nano-diamond and viscosity index improver according to the above-mentioned parts by weight Dissolve in the kettle, and use heat conduction oil to heat up to 155°C, so that the above raw materials are comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com