Method for recovering gold and copper from waste mobile telephone

A mobile phone recycling, motherboard technology, applied in the direction of improving process efficiency, can solve the problems of long leaching time, air pollutant emission, low efficiency, etc., and achieve the effect of selective recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

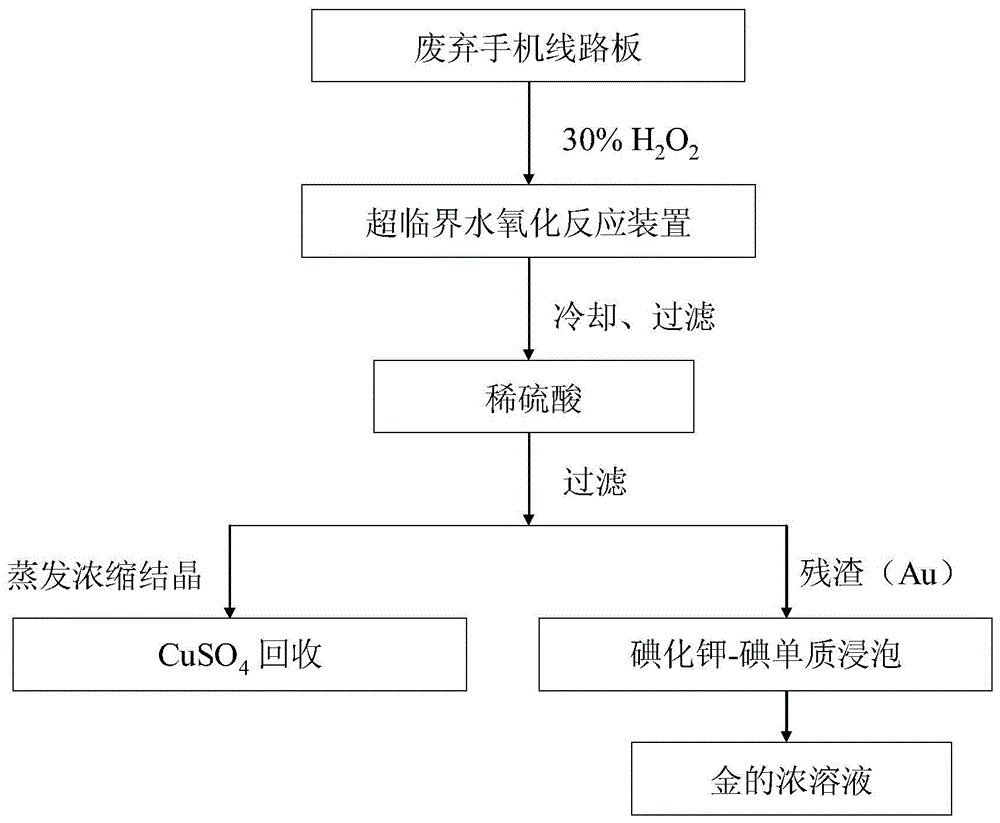

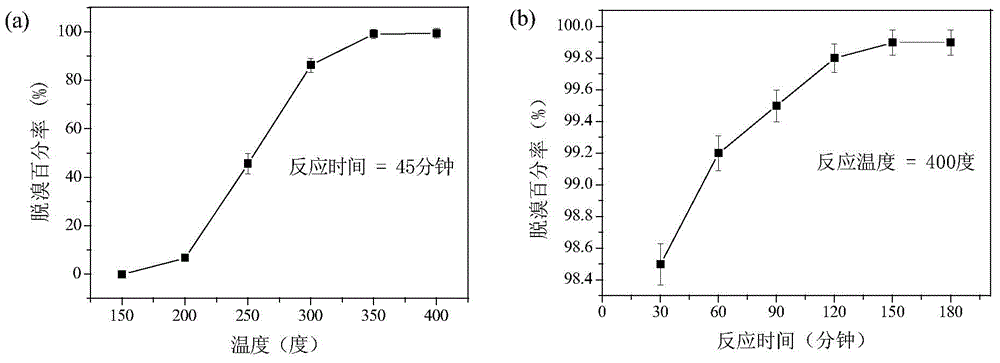

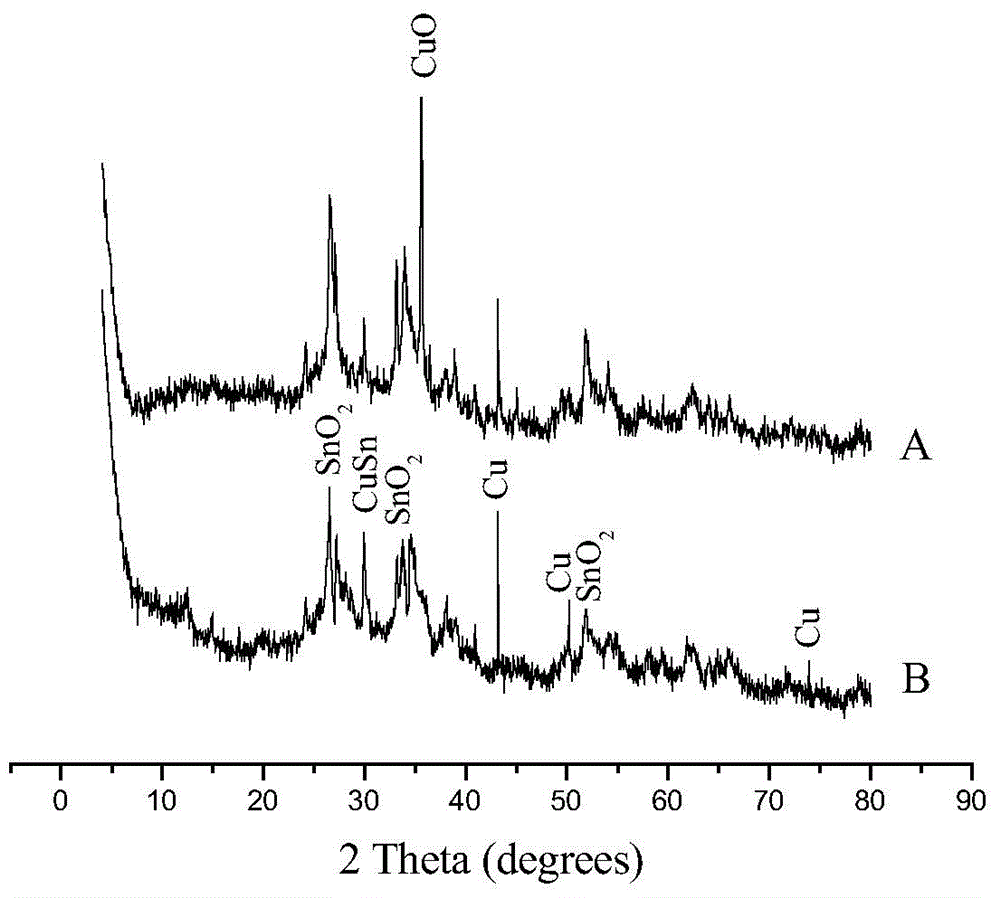

[0025] Such as figure 1 As shown, the main board and components of the discarded mobile phone circuit boards are separated, and the components are sorted and processed separately. Add the waste mobile phone circuit board fragments that have been cut into the supercritical water oxidation reaction device, add 50 milliliters of deionized water and 40 milliliters of 30% hydrogen peroxide, and immediately seal the reaction kettle (you can also feed oxygen 1- 5 minutes to replace hydrogen peroxide), heating, start timing after the temperature rose to 400 degrees, at this moment, the pressure in the container was controlled at 23MPa by a manual pressurization device, and stopped heating after 60 minutes of reaction. After the temperature dropped to room temperature, the reaction device was opened, and the reactant was transferred to a centrifuge tube for centrifugation. Take 1 ml of the aqueous phase after centrifugation and dilute it to a constant volume, and then use ion chromato...

Embodiment 2

[0027] Such as figure 1 As shown, the main board and components of the discarded mobile phone circuit boards are separated, and the components are sorted and processed separately. Add the waste mobile phone circuit board fragments that have been cut into the supercritical water oxidation reaction device, add 90 milliliters of deionized water and 60 milliliters of 30% hydrogen peroxide, immediately seal the reaction kettle (you can also feed oxygen 1- 5 minutes to replace hydrogen peroxide), heating, start timing after the temperature rose to 250 degrees, at this moment, the pressure in the container was controlled at 12MPa by a manual pressurization device, and stopped heating after 30 minutes of reaction. After the temperature dropped to room temperature, the reaction device was opened, and the reactant was transferred to a centrifuge tube for centrifugation. Take 1 ml of the aqueous phase after centrifugation and dilute it to a constant volume, and then use ion chromatograp...

Embodiment 3

[0029] Such as figure 1 As shown, the main board and components of the discarded mobile phone circuit boards are separated, and the components are sorted and processed separately. Add the waste mobile phone circuit board fragments that have been cut into the supercritical water oxidation reaction device, add 50 milliliters of deionized water and 40 milliliters of 30% hydrogen peroxide, and immediately seal the reaction kettle (you can also feed oxygen 1- 5 minutes to replace hydrogen peroxide), heating, start timing after the temperature rose to 400 degrees, at this moment, the pressure in the container was controlled at 30MPa by a manual pressurization device, and stopped heating after 180 minutes of reaction. After the temperature dropped to room temperature, the reaction device was opened, and the reactant was transferred to a centrifuge tube for centrifugation. Take 1 ml of the aqueous phase after centrifugation and dilute it to a constant volume, and then use ion chromat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com