W-type flame boiler combustion and pulverizing system

A boiler combustion and pulverization system technology, applied in the field of boiler combustion, to achieve the effects of improving combustion stability, reducing unit consumption of pulverization, and increasing furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

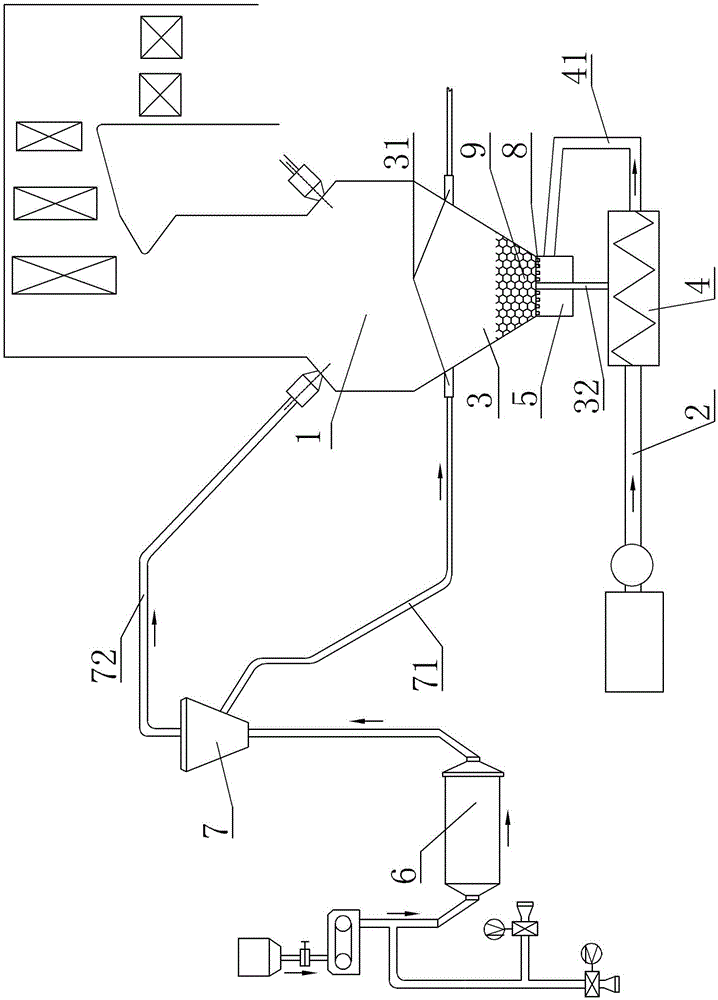

[0015] like figure 1 As shown, the W-type flame boiler combustion and pulverizing system of the present invention includes a furnace 1, a hot air pipe 2 drawn from the outlet of the air preheater, a cold ash hopper 3 arranged at the bottom of the furnace 1, and a furnace The burner at the front wall and the back wall, the slag cooler 4, the air chamber 5 installed at the bottom of the cold ash hopper 3, the raw coal bunker, coal feeder, coal mill 6 and pulverized coal separator 7 connected in sequence, Between the cold ash hopper 3 and the air chamber 5, there is an air distribution board 8, on which the bed material 9 is filled, wherein, several powder feeders are arranged on the front wall and the back wall of the cold ash hopper 3. Inlet 31, pulverized coal separator 7 includes powder return pipe 71 and powder outlet pipe 72, cold ash hopper 3 passes through air distribution plate 8 and air chamber 5 through a hot slag pipe 32 and is connected with slag cooler 4 to control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com