High-effect potassium-doped lead telluride-lead sulfide alloy thermoelectric material and preparation method thereof

A technology of thermoelectric materials and potassium doping, which is applied in the direction of thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of thermoelectric materials that need to be improved, and achieve the improvement of thermoelectric performance and energy conversion efficiency. The effect of high thermoelectric performance figure of merit and high energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

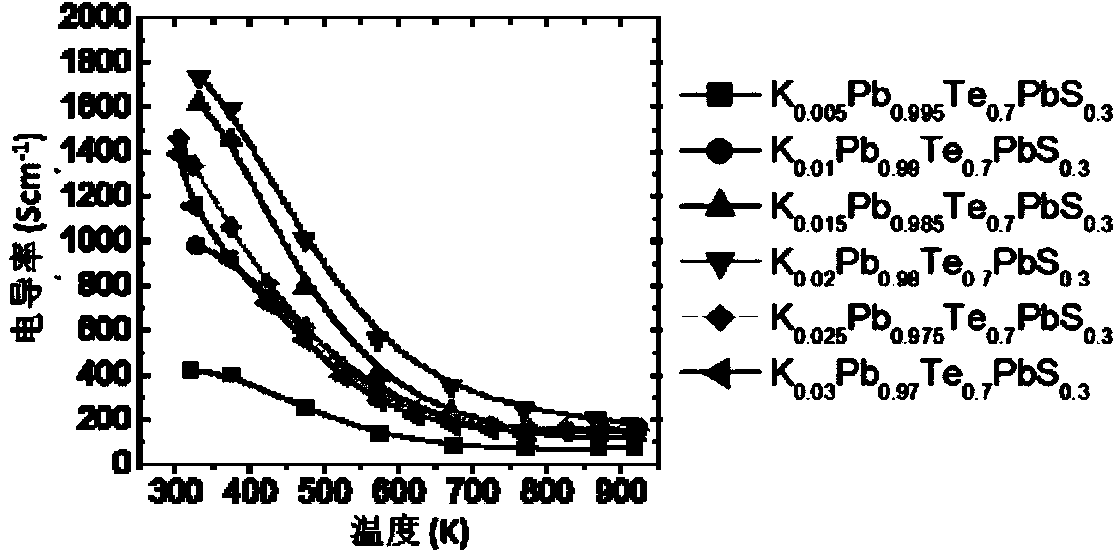

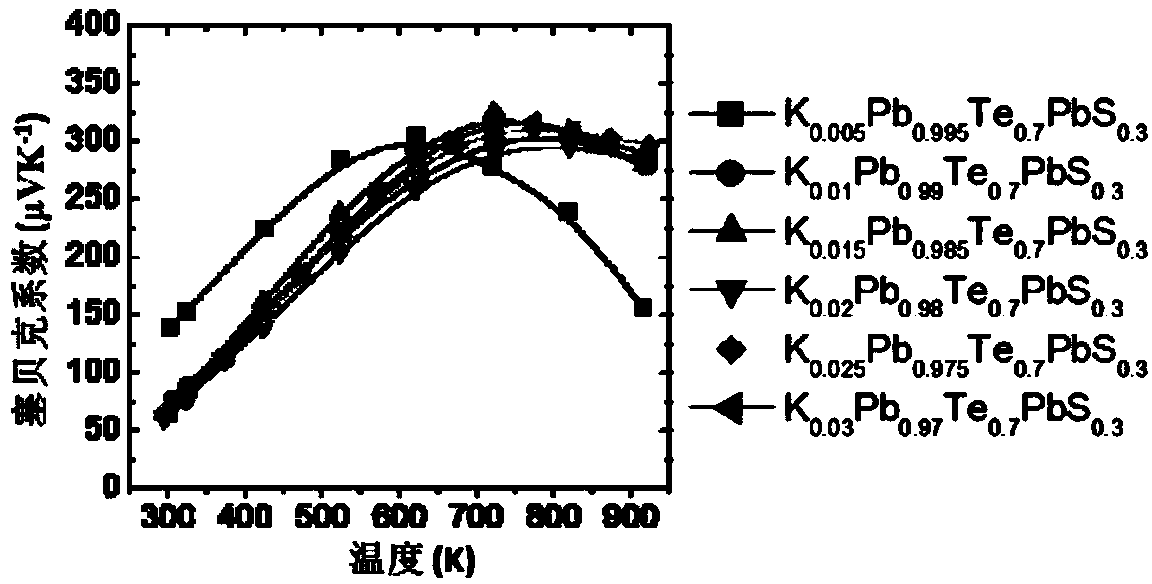

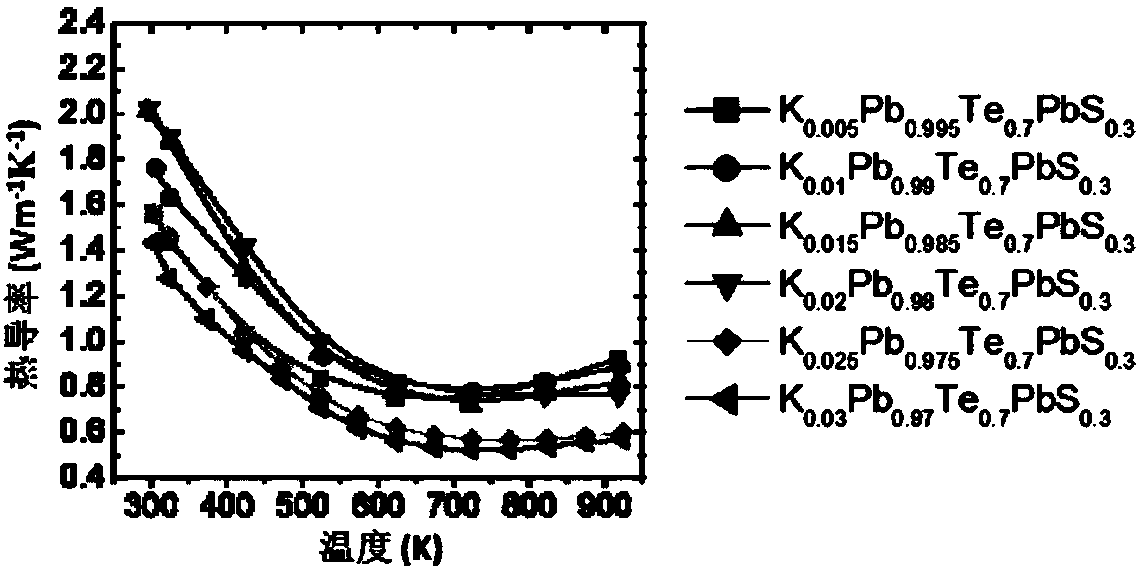

[0042] Embodiment 1: Preparation of potassium-doped lead telluride-lead sulfide alloy material

[0043] Raw materials: Pb (99.99%, American Elements, USA), Te (99.999%, 5N Plus, Canada), S (99.999%, 5N Plus, Canada), K (99.999%, Sigma-Aldrich, USA) .

[0044] Preparation steps: in a nitrogen atmosphere glove box, according to the molar ratio of Pb, Te, S and K is 0.995:0.7:0.3:0.005, high-purity Pb, Te, S and K raw materials are melted on the carbon coating Mix well in the quartz tube, then, adjust the pressure in the quartz tube to be about 10 -4 Then, the carbon-coated fused silica tube was sealed, and then, under the condition of 1323K, the sealed carbon-coated fused silica tube containing the raw material mixture was smelted for 10 hours, and then the furnace was cooled to room temperature to obtain an ingot, and subsequently, The resulting ingot was crushed in a mortar to a grain size of less than 5mm 3 , and then, the obtained particles were mechanically milled to a g...

Embodiment 2

[0045] Embodiment 2: Preparation of potassium-doped lead telluride-lead sulfide alloy material

[0046] Potassium-doped lead telluride-lead sulfide alloy material was prepared according to the method of Example 1, except that the molar ratio of Pb, Te, S and K was 0.99:0.7:0.3:0.01.

Embodiment 3

[0047] Embodiment 3: Preparation of potassium-doped lead telluride-lead sulfide alloy material

[0048] Potassium-doped lead telluride-lead sulfide alloy material was prepared according to the method of Example 1, except that the molar ratio of Pb, Te, S and K was 0.985:0.7:0.3:0.015.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com