Preparation method and application of modified hydroxyapatite microcapsule biological material carrier

A technology of hydroxyapatite and biological materials, which is applied in the directions of non-active ingredients, such as medical preparations, drug delivery, and pharmaceutical formulations, can solve the problems of low carrying capacity, easy dissipation, and difficult control of the release process, and achieves low cost. , type and dosage are small, the effect of active ingredient isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 (product preparation):

[0051] A modified hydroxyapatite microcapsule biological material carrier, the preparation steps of which are as follows:

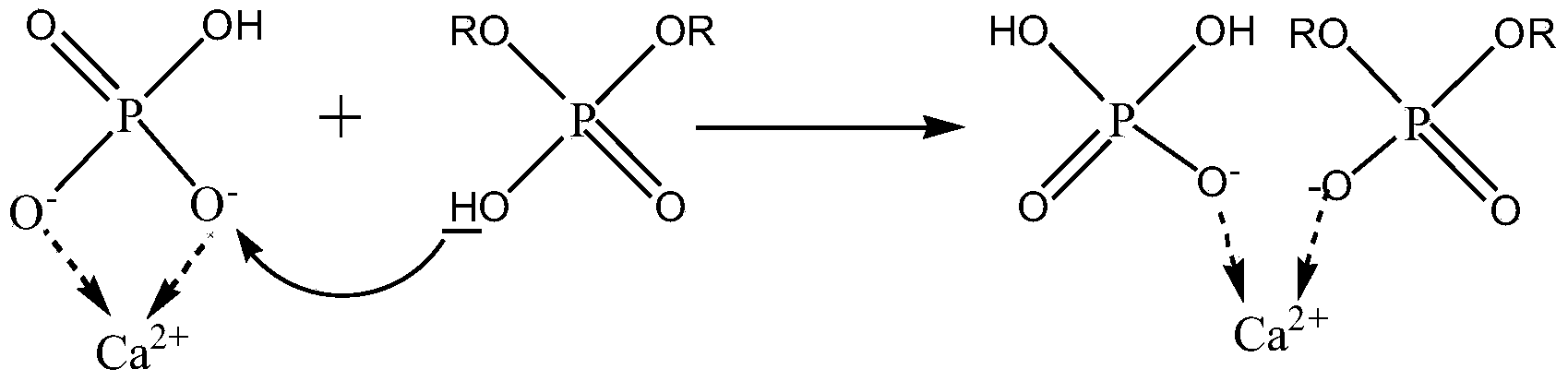

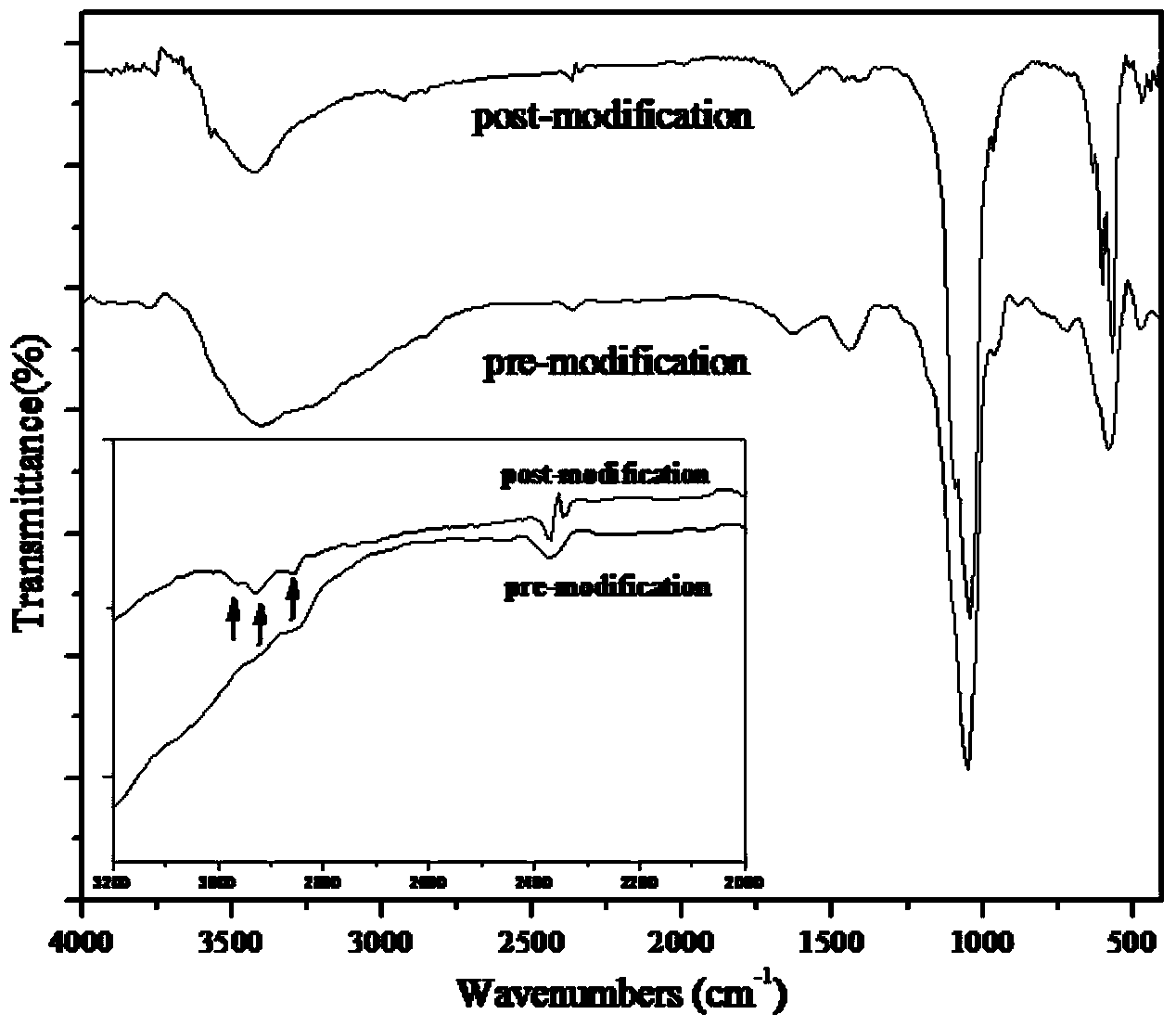

[0052] (1) Modification of hydroxyapatite nanoparticles:

[0053] 0.500g (4.98×10 -4 mol) hydroxyapatite nanoparticles were placed in a round bottom flask, then 0.5mmol of dibutyl phosphate was added, and then 50ml of acetone was added to disperse to form a reaction system. The concentration of dibutyl phosphate in the reaction system was 0.01mol / L. Under the condition of 57°C water bath, stir and reflux for 5 hours; after the reflux, the product is separated by suction filtration, and then the product is washed 8 times with acetone by suction filtration; the washed product nanoparticles are collected and dried in a vacuum oven at 60°C for 24 Hour.

[0054] (2) Preparation of modified hydroxyapatite microcapsule biomaterial carrier:

[0055] Put 20 mg of the dried product nanoparticles obtained in step (1) ...

Embodiment 2

[0056] Embodiment 2 (product preparation):

[0057] A modified hydroxyapatite microcapsule biological material carrier, the preparation steps of which are as follows:

[0058] (1) Modification of hydroxyapatite nanoparticles:

[0059] 0.500g (4.98×10 -4 mol) hydroxyapatite nanoparticles were placed in a round bottom flask, then 0.5mmol of dibutyl phosphate was added, and then 50ml of acetone was added to disperse to form a reaction system. The concentration of dibutyl phosphate in the reaction system was 0.01mol / L. Under the condition of a water bath at 57°C, stir and reflux for 5 hours; after the reflux, separate the product by suction filtration, and then wash the product 8 times with acetone by suction filtration. The product nanoparticles after washing were collected and dried in a vacuum oven at 60° C. for 24 hours.

[0060] (2) Preparation of modified hydroxyapatite microcapsule biomaterial carrier:

[0061] Put 20 mg of the dried product nanoparticles obtained in st...

Embodiment 3

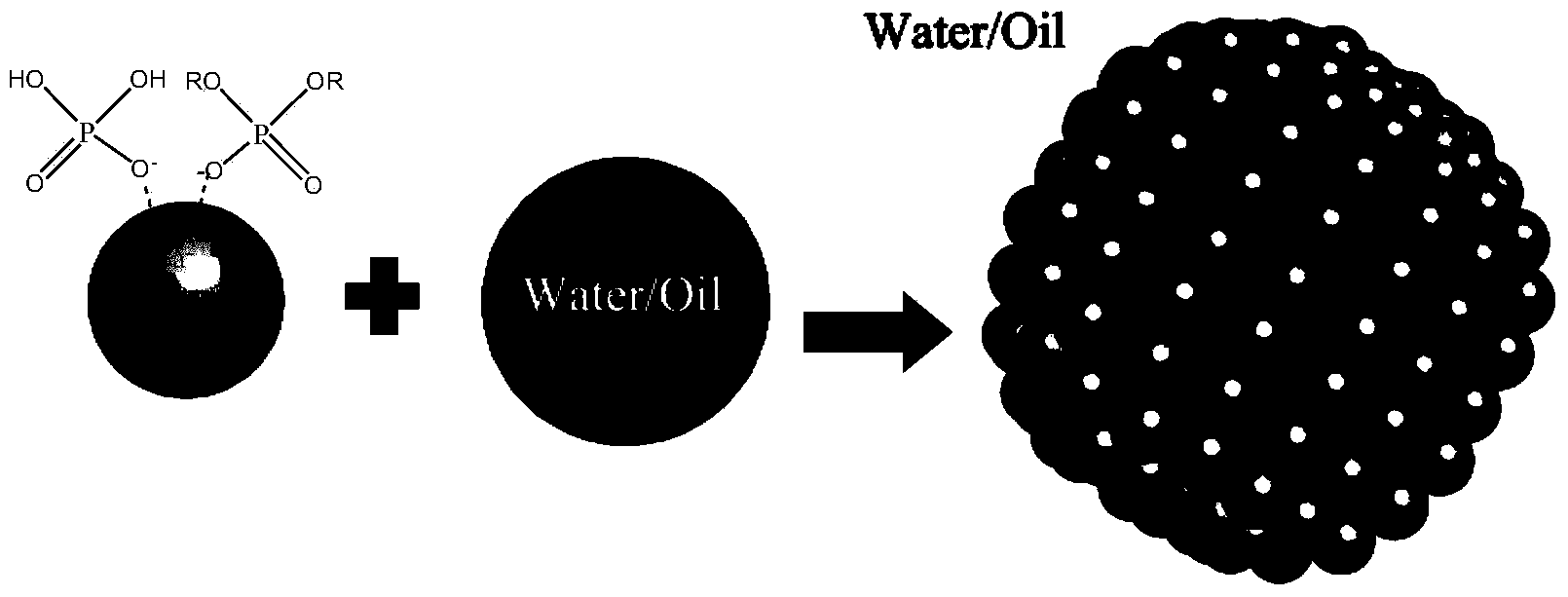

[0062] Embodiment 3 (application): hydroxyapatite microcapsule material is used as the carrier application experiment of fluorescent dye calcein

[0063] Choose to use 10 -5 The mol / l calcein physiological saline solution is used as the water phase, and the edible oil is used as the oil phase. Calcein is a small molecule water-soluble fluorescein with stable properties and can be easily detected by fluorescence spectrophotometry or ultraviolet-visible spectrophotometry. It is often used as a model drug for drug carriers.

[0064] Use 1ml of edible oil as the oil phase, add 20 mg of the modified hydroxyapatite nanoparticles prepared in step (1) of Example 1, use ultrasonic waves to fully disperse it in the oil phase, and then add 100 μl of 10 -5 mol / l calcein saline solution, shake vigorously to form emulsion. Observation with an optical microscope: it can be seen that the microcapsule material is formed with calcein saline solution as the core material and modified hydroxyap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com