Preparation method of flexible silicon dioxide aerosol

A silica and aerogel technology, applied in the direction of silica, silica, etc., can solve the problems of performance impact, low thermal stability temperature of samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] According to the atomic molar ratio of 1:13, 4ml of methyltriethoxysilane, 11.2ml of methanol, and 1.30ml of oxalic acid solution with a molar concentration of 0mol / L were measured according to the atomic molar ratio of 1:4, and the reaction system was mixed evenly by magnetic stirring for 30min. Let stand for 12h. According to the mass ratio of methyltriethoxysilane and hydroxyl-terminated polydimethylsiloxane 1:0.025, add 0.09ml of hydroxyl-terminated polydimethylsiloxane, and then add methyltriethoxysilane and ammonia atom Add 13.36mol / L ammonia solution at a molar ratio of 1:4 and stir for 30 min to form a silica sol.

[0018] Let the silica sol stand at room temperature until the gel is formed, age the gel at 60°C for 2 days, wash and replace it with ethanol 5 times during this period, and dry the sample with supercritical fluid to obtain silica airgel .

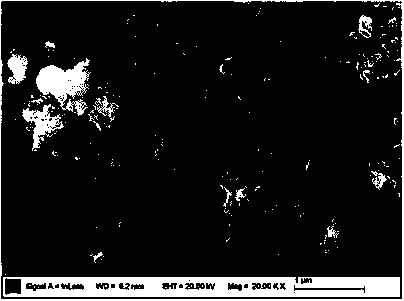

[0019] as attached figure 1 As shown in the scanning electron microscope (SEM) image, the obtained elastic ...

Embodiment 2

[0021] Measure 6ml of methyltriethoxysilane, 22.4ml of methanol according to the atomic molar ratio of 1:19.5, and 1.96ml of oxalic acid solution with a molar concentration of 0.001mol / L according to the atomic molar ratio of 1:4, and magnetically stir for 30 minutes to make the reaction system mix evenly , let stand for 24h. According to the mass ratio of methyltriethoxysilane and hydroxyl-terminated polydimethylsiloxane 1:0.05, add 0.27ml of hydroxyl-terminated polydimethylsiloxane, and then add methyltriethoxysilane and ammonia atom Add 10mol / L ammonia solution at a molar ratio of 1:4 and stir for 30min to form a silica sol.

[0022] Leave the silica sol at room temperature until the gel is formed, age the gel at 40°C for 3 days, wash and replace it with methanol 7 times during this period, and dry the sample with supercritical fluid to obtain silica aerogel .

Embodiment 3

[0024] According to the atomic molar ratio of 1:26, 4ml of methyltriethoxysilane, 22.4ml of methanol, and 1.30ml of oxalic acid solution with a molar concentration of 0.01mol / L were measured according to the atomic molar ratio of 1:4, and the reaction system was mixed evenly by magnetic stirring for 30 minutes. , let stand for 36h. According to the mass ratio of methyltriethoxysilane and hydroxyl-terminated polydimethylsiloxane 1:0.075, add 0.27ml of hydroxyl-terminated polydimethylsiloxane, and then add methyltriethoxysilane and ammonia atom Add 8 mol / L ammonia solution at a molar ratio of 1:4, stir for 30 min to form a silica sol.

[0025] Leave the silica sol at room temperature until the gel is formed, age the gel at 40°C for 3 days, wash and replace it with methanol 7 times during this period, and dry the sample with supercritical fluid to obtain silica aerogel .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com