Semidry-process desulfurization ash putty for interior wall

A semi-dry desulfurization and interior wall putty technology, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of wall beauty discount, easy mold, bacteria breeding, etc., and achieve water resistance Good, eliminate the harm to the human body, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In the embodiment of this application, a semi-dry desulfurization gray interior wall putty is described.

[0020] The composition of the interior wall putty is (according to the mass percentage): semi-dry desulfurization ash 25% to 35%, steel slag 10% to 20%, slag fine powder 30% to 45%, Shuangfei powder 10% to 25%, water retaining agent 0 %~5%, latex powder 0%~5%.

[0021] Among them, the semi-dry desulfurization ash is specifically the desulfurization ash produced by the semi-dry flue gas desulfurization system of the iron and steel plant.

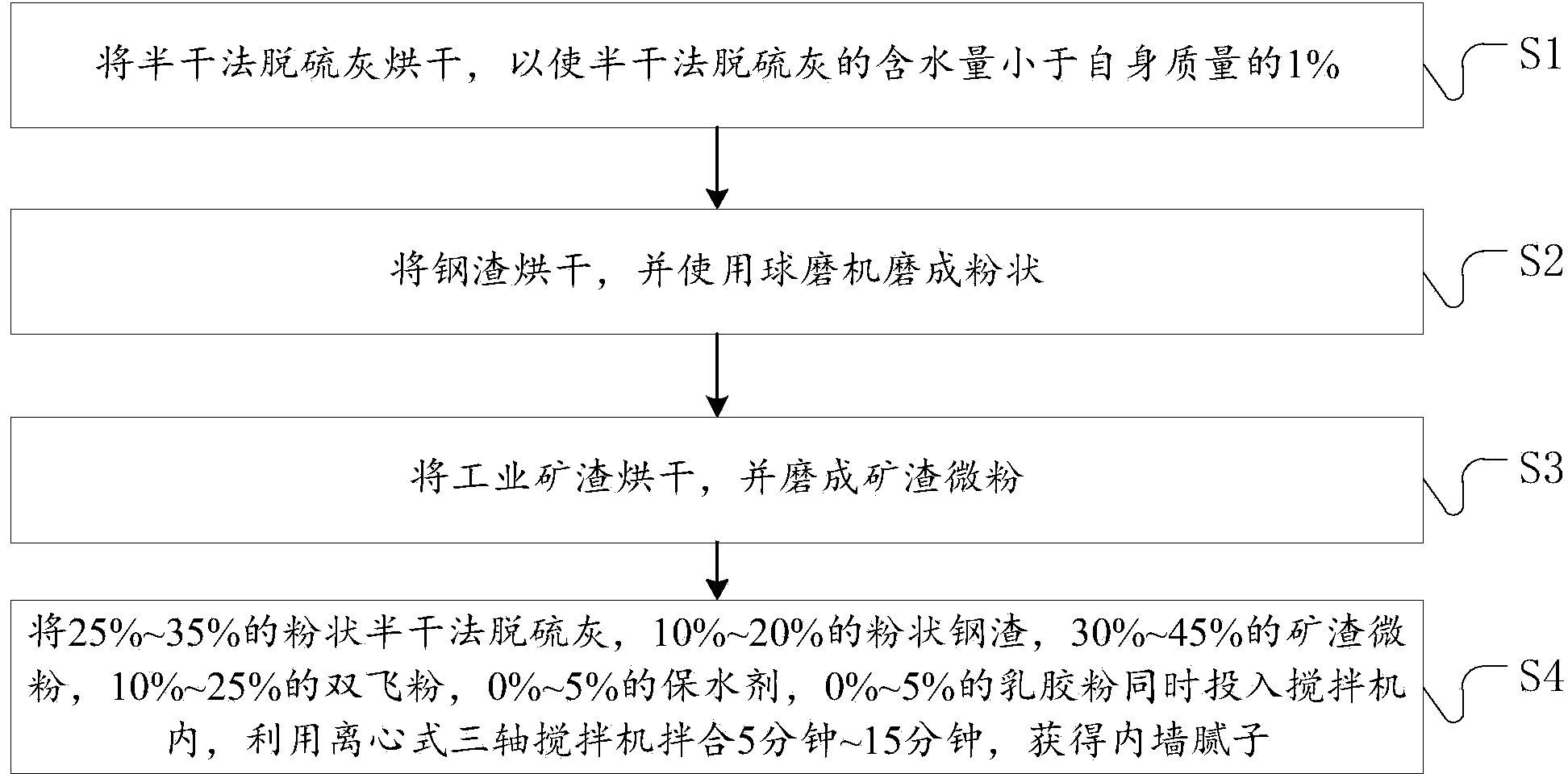

[0022] Further, please refer to the preparation method of the interior wall putty of the present invention figure 1 ,include:

[0023] S1, drying the semi-dry desulfurization ash so that the water content of the semi-dry desulfurization ash is less than 1% of its mass.

[0024] S2, drying the steel slag, and using a ball mill to grind it into powder.

[0025] In a specific implementation process, after drying the semi-dry desu...

Embodiment 2

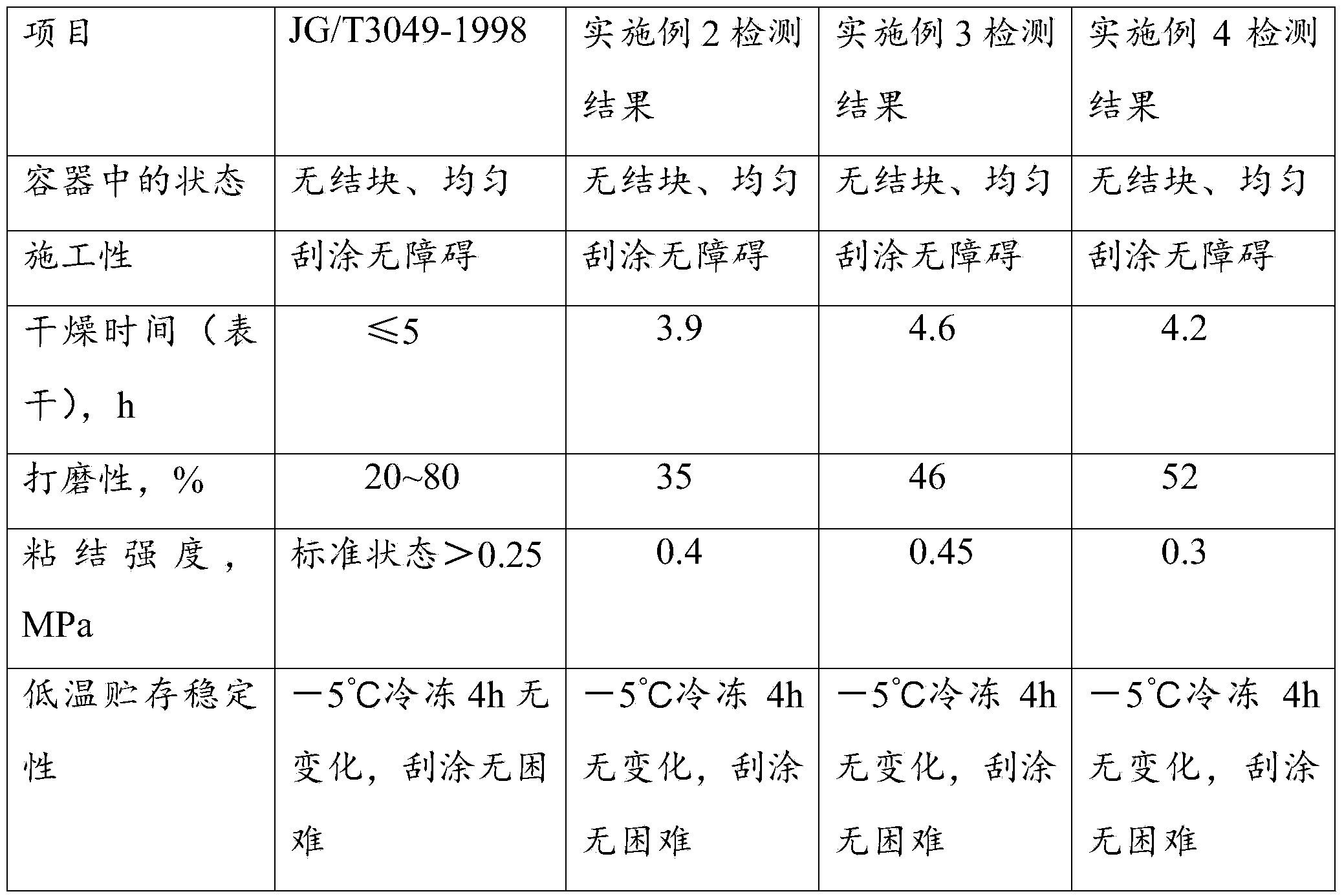

[0030] Take the sintered semi-dry desulfurization ash from the iron and steel plant, steel slag after iron selection, and slag and put them in an oven at 100°C for drying. %. After drying, the steel slag and slag are ground into powder. After grinding, the fineness of the steel slag is above 350 mesh, and the specific surface area of the slag fine powder is not less than 450m 2 / kg spare.

[0031] Weigh 25% desulfurization ash, 15% powdered steel slag, 40% slag powder, 15% double fly powder, 2% water retaining agent, 3% latex powder, and put the above raw materials into the mixer at the same time , use a centrifugal three-shaft mixer to mix for 15 minutes, stir evenly, and then pack it with a baler or air pressure pump and send it into a vacuum tank for storage.

Embodiment 3

[0033] Take the sintered semi-dry desulfurization ash from the iron and steel plant, steel slag after iron selection, and slag and put them in an oven at 100°C for drying. %. After drying, the steel slag and slag are ground into powder. After grinding, the fineness of steel slag is above 350 mesh, and the specific surface area of slag powder is not less than 450m 2 / kg spare. Weigh 30% desulfurization ash, 10% powdered steel slag, 45% slag powder, 10% double fly powder, 1% water retaining agent, 4% latex powder, and put the above raw materials into the mixer at the same time , use a centrifugal three-shaft mixer to mix for 15 minutes, stir evenly, and then pack it with a baler or air pressure pump and send it into a vacuum tank for storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com