Rubber antiager

A technology of rubber anti-aging agent and anti-aging agent, applied in the field of rubber anti-aging agent, can solve the problems of easy migration and volatilization of anti-aging agent BHT, reduction of anti-aging performance, environmental pollution, etc., to improve product quality and economic benefits, good anti-aging performance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

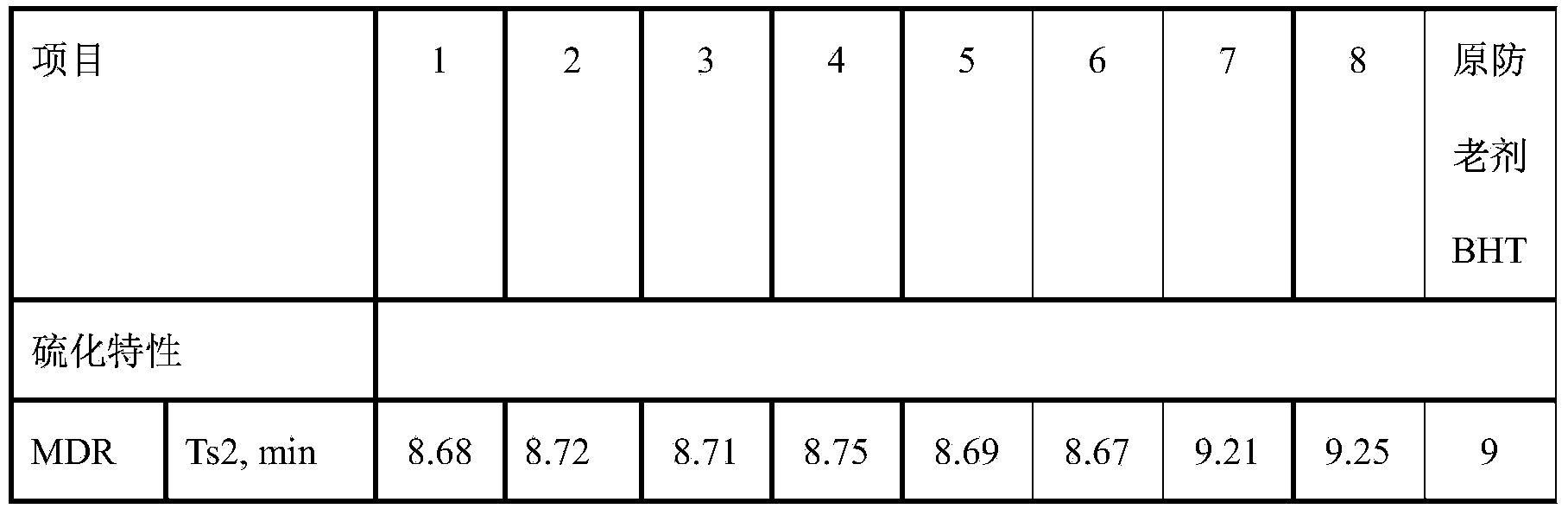

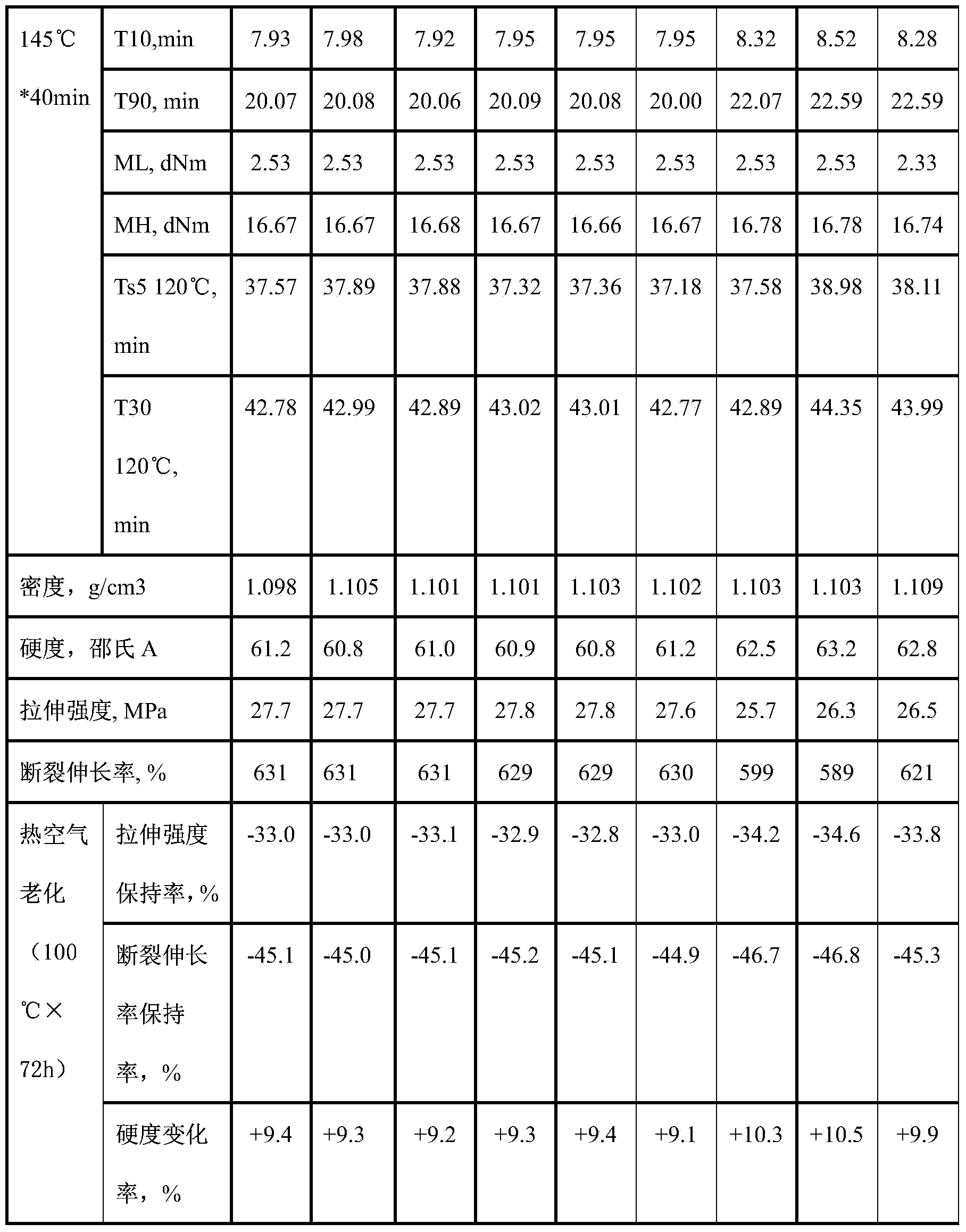

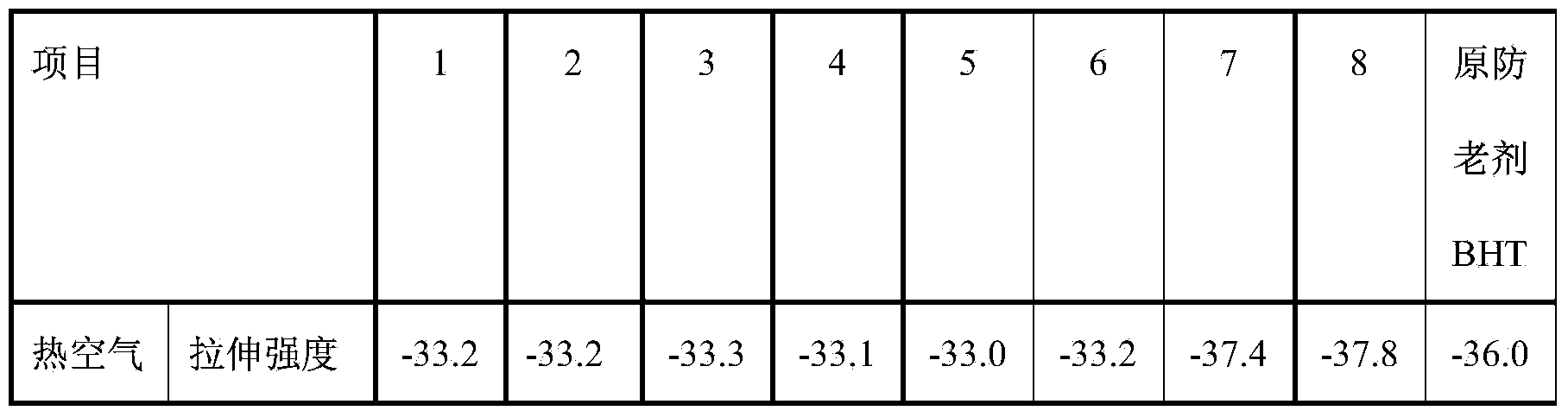

Embodiment 1

[0013] Under normal temperature conditions, dry 40% calcium terephthalate at 120°C for 0.5 h, add 20% silane coupling agent Si69 to calcium terephthalate under nitrogen atmosphere, and mix well Evenly, stay activated for 0.5h, heat the anti-aging agent BHT with a mass ratio of 40% to a molten state, add the activated mixture, and mix well to obtain the No. 1 anti-aging agent obtained in the present invention.

Embodiment 2

[0015] Dry magnesium terephthalate with a mass ratio of 20% at 100°C for 1 hour, and add silane coupling agent Si75 with a mass ratio of 30% to magnesium terephthalate under a nitrogen atmosphere, mix well, and stay activated for 1 hour , heating antiaging agent BHT with a mass ratio of 50% to a molten state, adding the activated mixture, and mixing thoroughly to obtain No. 2 antiaging agent of the present invention.

Embodiment 3

[0017] Dry zinc terephthalate with a mass ratio of 50% at 110°C for 1 hour, and add silane coupling agent KH-580 with a mass ratio of 15% and silane coupling agent KH-550 with a mass ratio of 15% to the In the zinc phthalate, mix well, stay and activate for 0.5h, heat the anti-aging agent BHT with a mass ratio of 20% to a molten state, add the activated mixture, and mix well to obtain the No. 3 anti-aging agent obtained in the present invention .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com