Copper smelting furnace high-temperature flue gas two-stage organic Rankine cycle waste heat power generating method

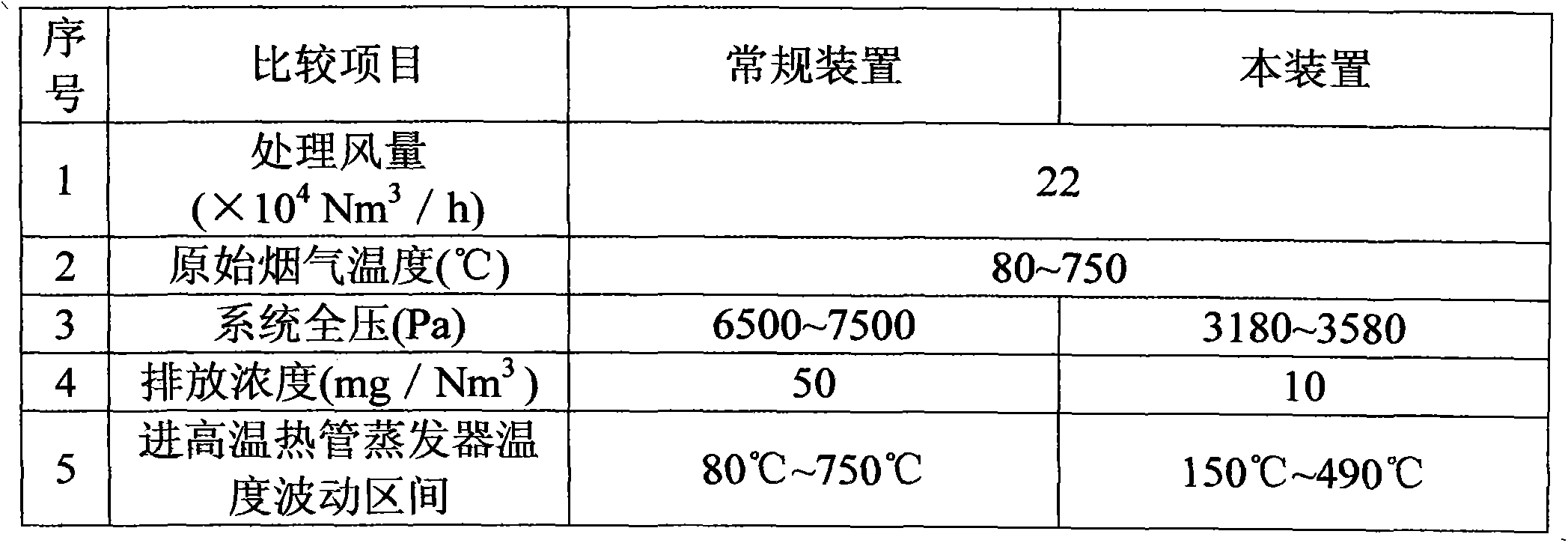

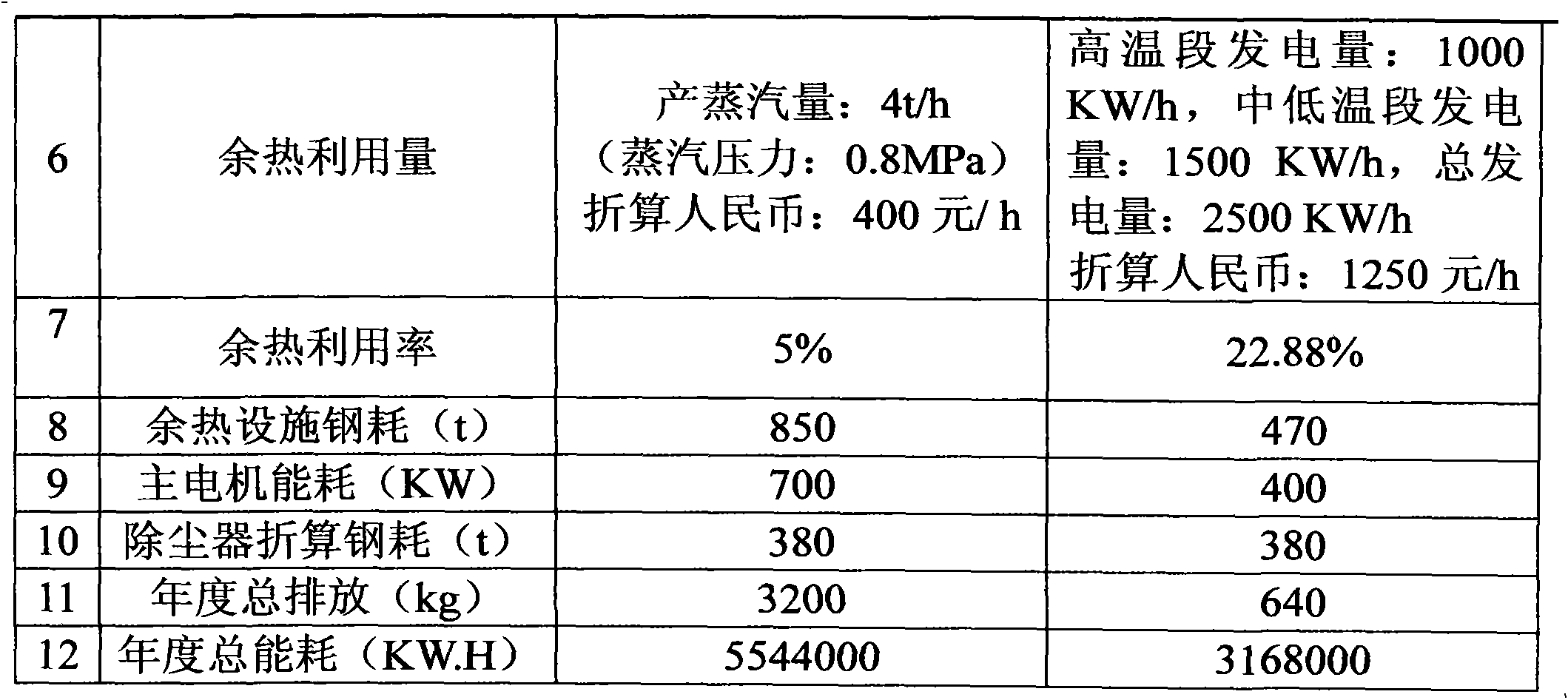

A technology of high-temperature flue gas and waste heat power generation, which can be used in machines/engines, furnaces, waste heat treatment, etc., to solve problems such as low steam output, and achieve the effect of reducing investment, lowering the maximum temperature, and reducing the fluctuation range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

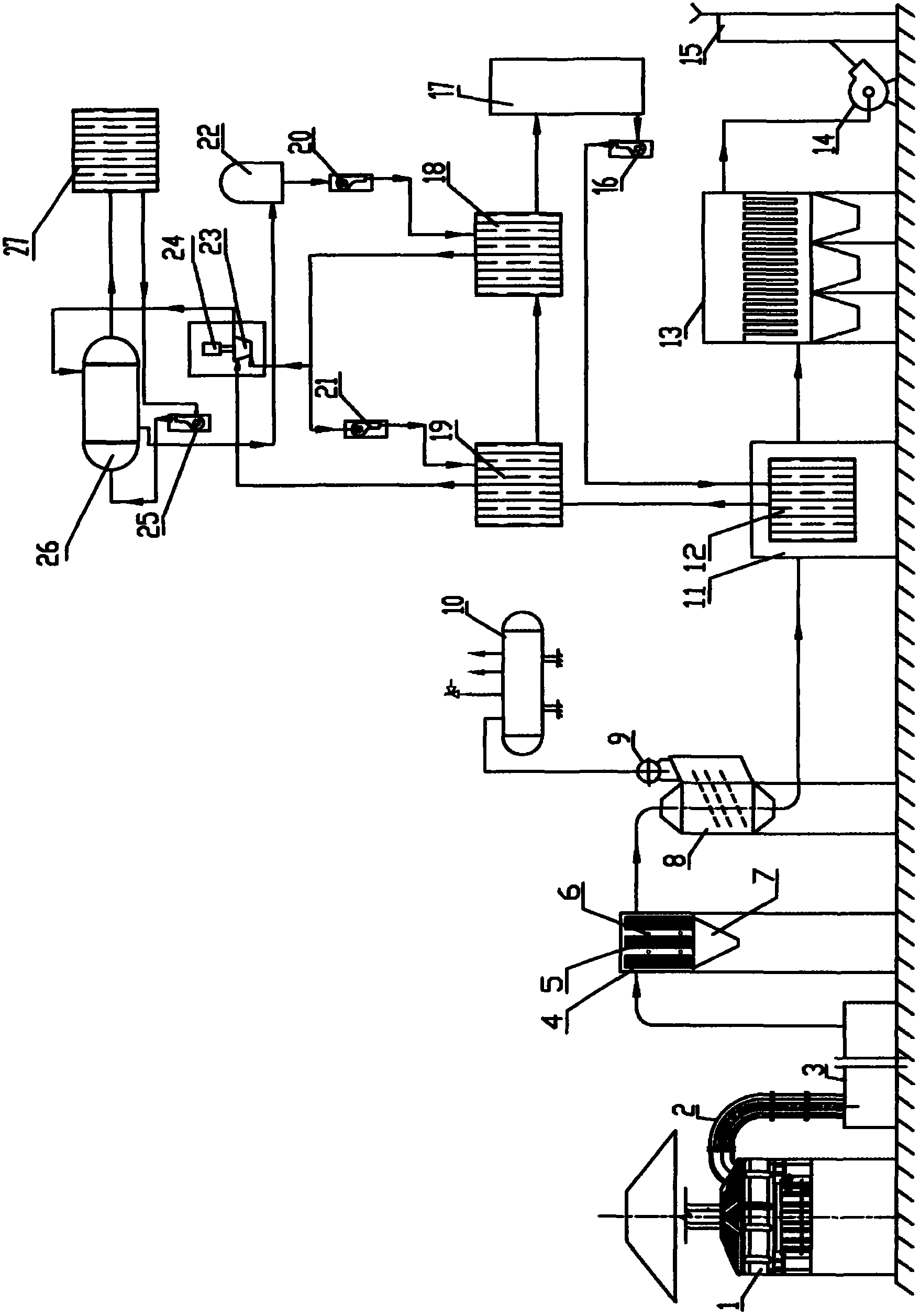

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

[0021] Such as figure 1 Shown: the steps of the second-stage organic Rankine cycle waste heat power generation method of copper smelting furnace high-temperature flue gas of the present invention are as follows:

[0022] 35t / h copper smelting furnace 1 flue gas flow rate 22×10 4 N m 3 / h, temperature 750℃, dust concentration 15g / Nm 3 It is discharged from the furnace, mixed with cold air through the water-cooled flue 2, and enters the combustion settling chamber 3 after burning carbon monoxide gas; The cold wind finally burns carbon monoxide gas, and the flue gas from the combustion settling chamber 3 enters the heat storage homogenizer 4, which includes a carbon-silicon composite material heat storage body 5, a shock wave ash cleaning device 6 and The ash hopper 7, the shock wave cleaning device 6 is arranged between the carbon-silicon composite regenerators 5 in sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com