Solar-blind ultraviolet irradiation calibrating device

An external irradiation and calibration technology, applied in the field of ultraviolet radiation calibration, can solve the problems of low accuracy and narrow dynamic range of solar-blind ultraviolet testing, and achieve the effects of easy operation, highly automated testing process, and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

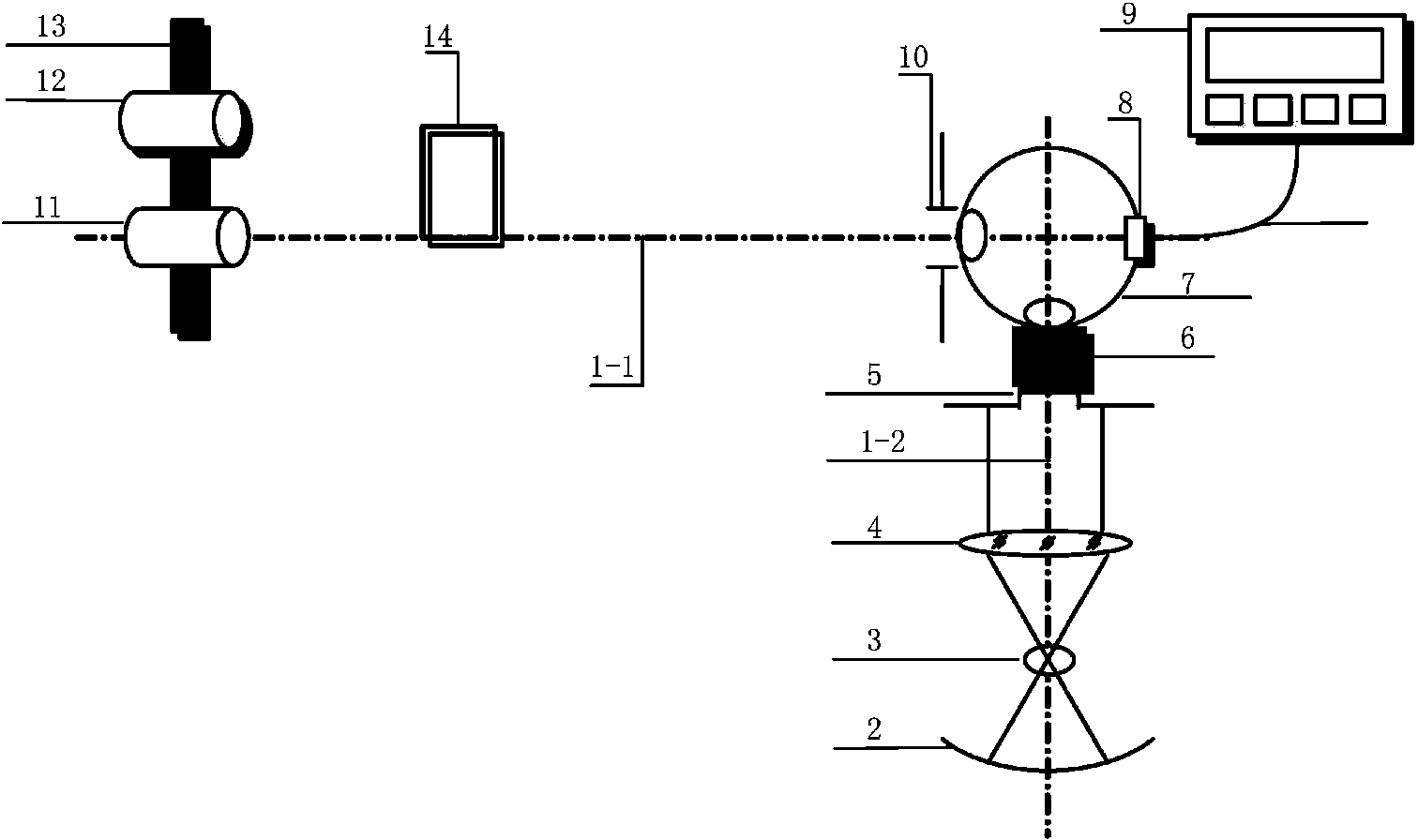

[0010] Specific implementation mode one, combination figure 1 In this embodiment, a large dynamic range solar-blind ultraviolet irradiance calibration device includes an optical track 1, which is L-shaped, and includes a main optical track 1-1 and a sub-optical track 1-2 perpendicular to each other, and the main optical track is 8m long. , Straightness≤±0.5mm, and the length of the secondary optical track is 2m. A condenser lens 2, an ultraviolet light source 3, a collimator lens 4, an entrance aperture 5 and a shielding cover 6 are sequentially installed on the secondary light track; the integrating sphere 7 is set at the vertical position of the main light track 1-1 and the secondary light track 1-2 . An exit aperture 10 and a horizontal electric displacement stage 13 are sequentially installed on the main optical track 1-1. The ultraviolet light source 3 is a highly stable ultraviolet deuterium lamp, which is used in conjunction with the condenser lens 2 and the collimator ...

specific Embodiment approach 2

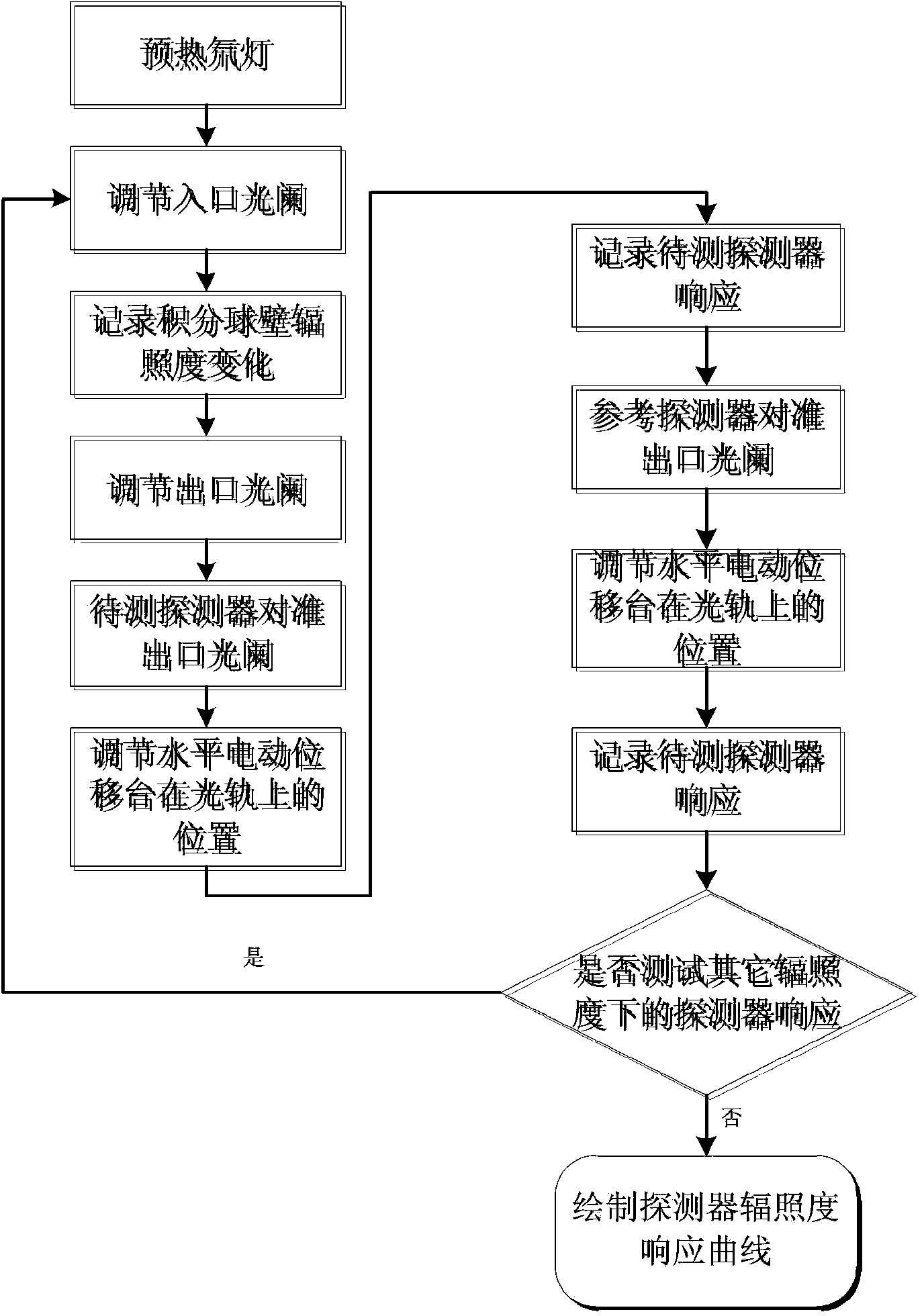

[0013] Specific implementation mode two, combination figure 2 This embodiment will be described. This embodiment is a method of using the solar-blind ultraviolet irradiance calibration device described in the first embodiment to test the irradiance response of a solar-blind ultraviolet detector, which has the following steps:

[0014] 1. Preheat the deuterium lamp for half an hour;

[0015] 2. Adjust the entrance aperture 5, and record the irradiance change of the inner wall of the integrating sphere 7 according to the reading of the weak current meter 9;

[0016] 3. Adjust the exit aperture 10;

[0017] 4. Mount the detector 11 to be tested on the horizontal electric translation stage 13 and adjust its position on the horizontal electric stage 13, and use the laser 14 to align the detector 11 to be measured at the center of the exit aperture 10;

[0018] 5. Adjust the position of the horizontal electric translation stage 13 on the main optical track 1-1 so that the distance between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com