Carbon-coated transition metal oxide or transition metal nanoparticle composite electrode material adopting cellular structure and preparation method thereof

A transition metal, microporous structure technology, applied in battery electrodes, structural parts, circuits, etc., to achieve the effect of reducing volume change, shortening diffusion distance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation process of the carbon-coated transition metal oxide nanoparticle composite electrode material with microporous structure is as follows,

[0036] Specifically in two steps: 1. Synthesis of tin alginate:

[0037] Add 20 g of sodium alginate into 500 mL of deionized water, and heat and stir at 65° C. for 6 hours to completely dissolve it. Afterwards, 30 grams of tin dichloride was added to 400 mL of deionized water, 2 mL of hydrochloric acid solution (1M) was added, and stirred for 20 minutes to completely dissolve it. Then the two solutions are fully mixed for 2 hours to obtain tin alginate precipitation; after centrifugation and washing, dry at 60°C for 20 hours to obtain the tin alginate precursor;

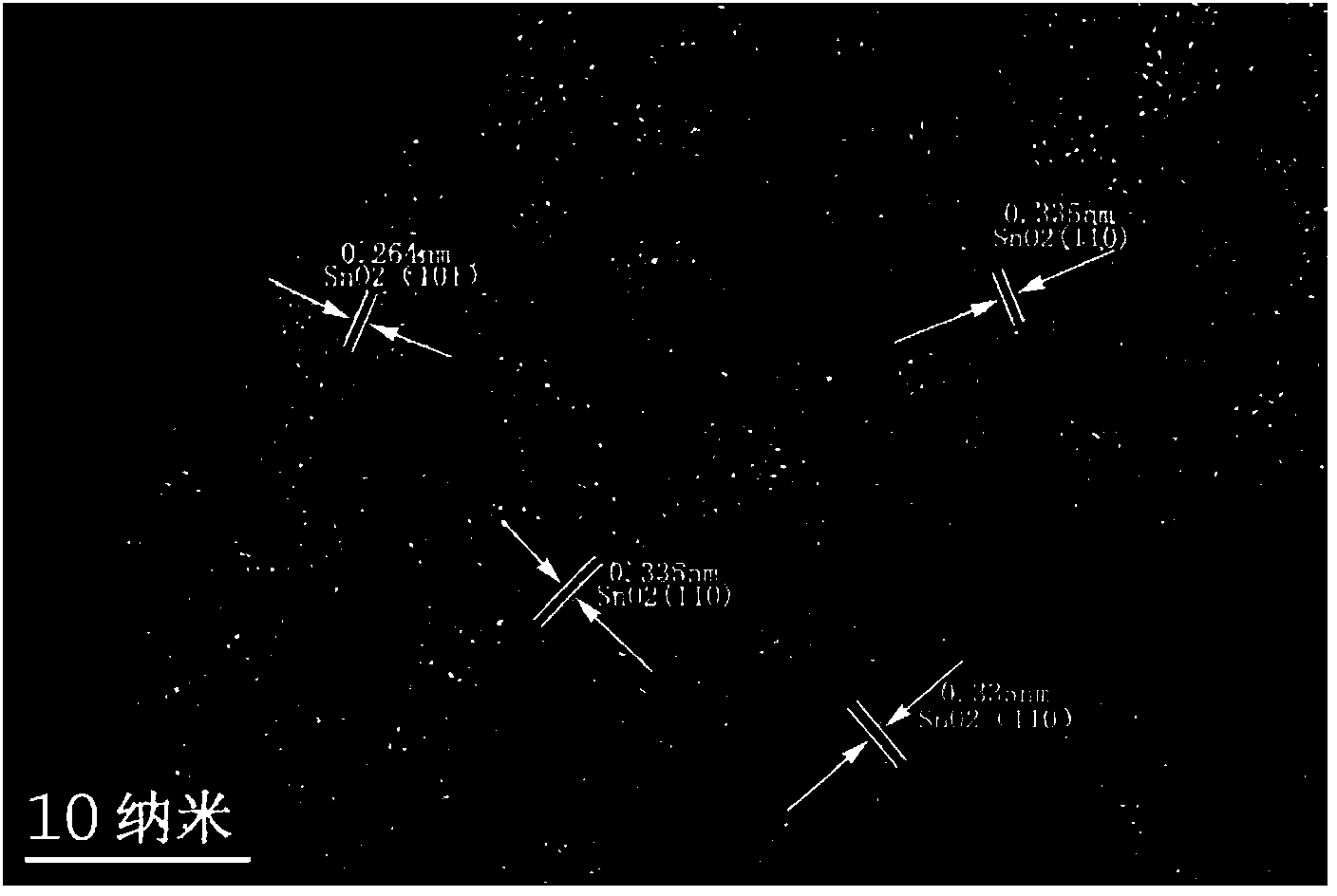

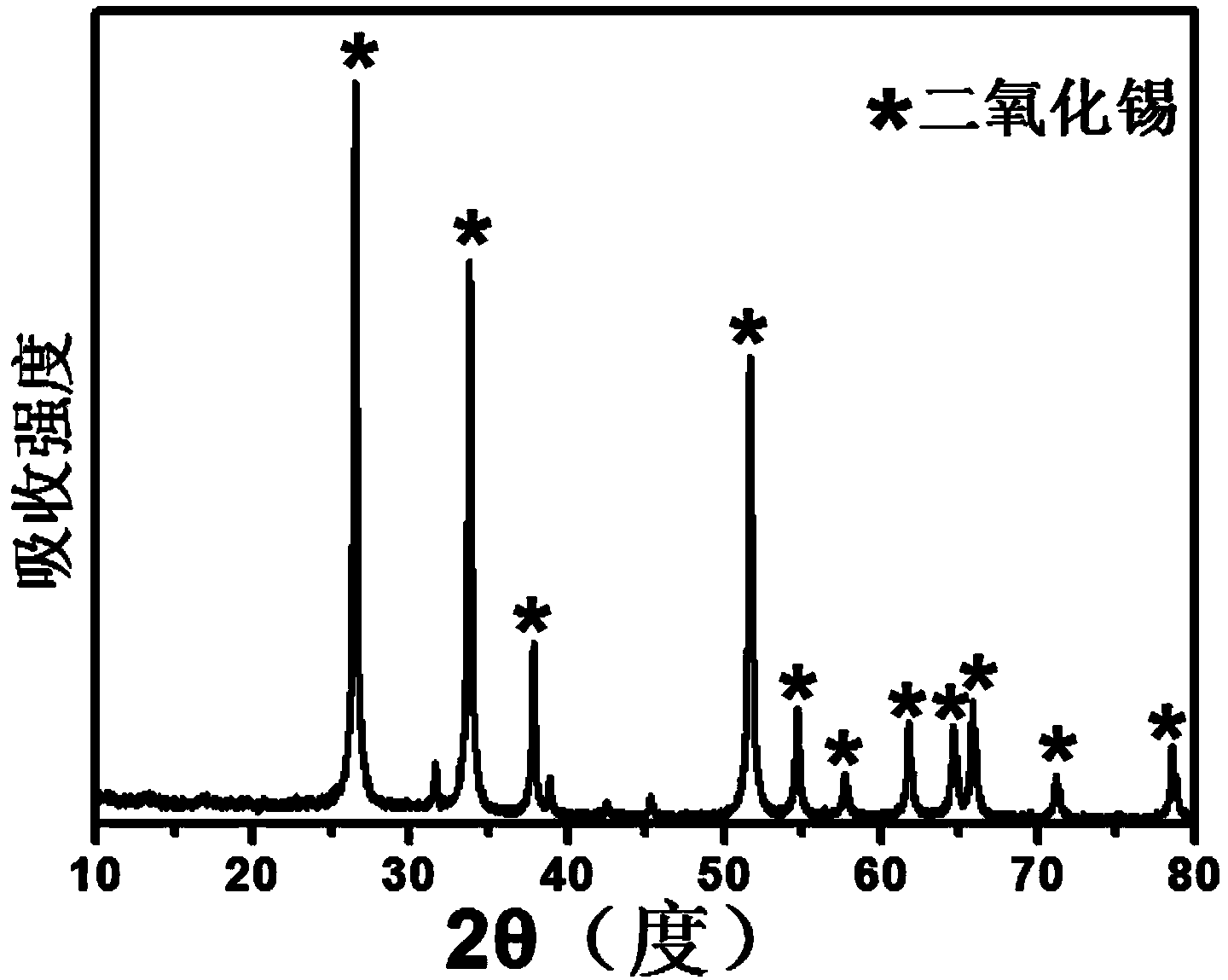

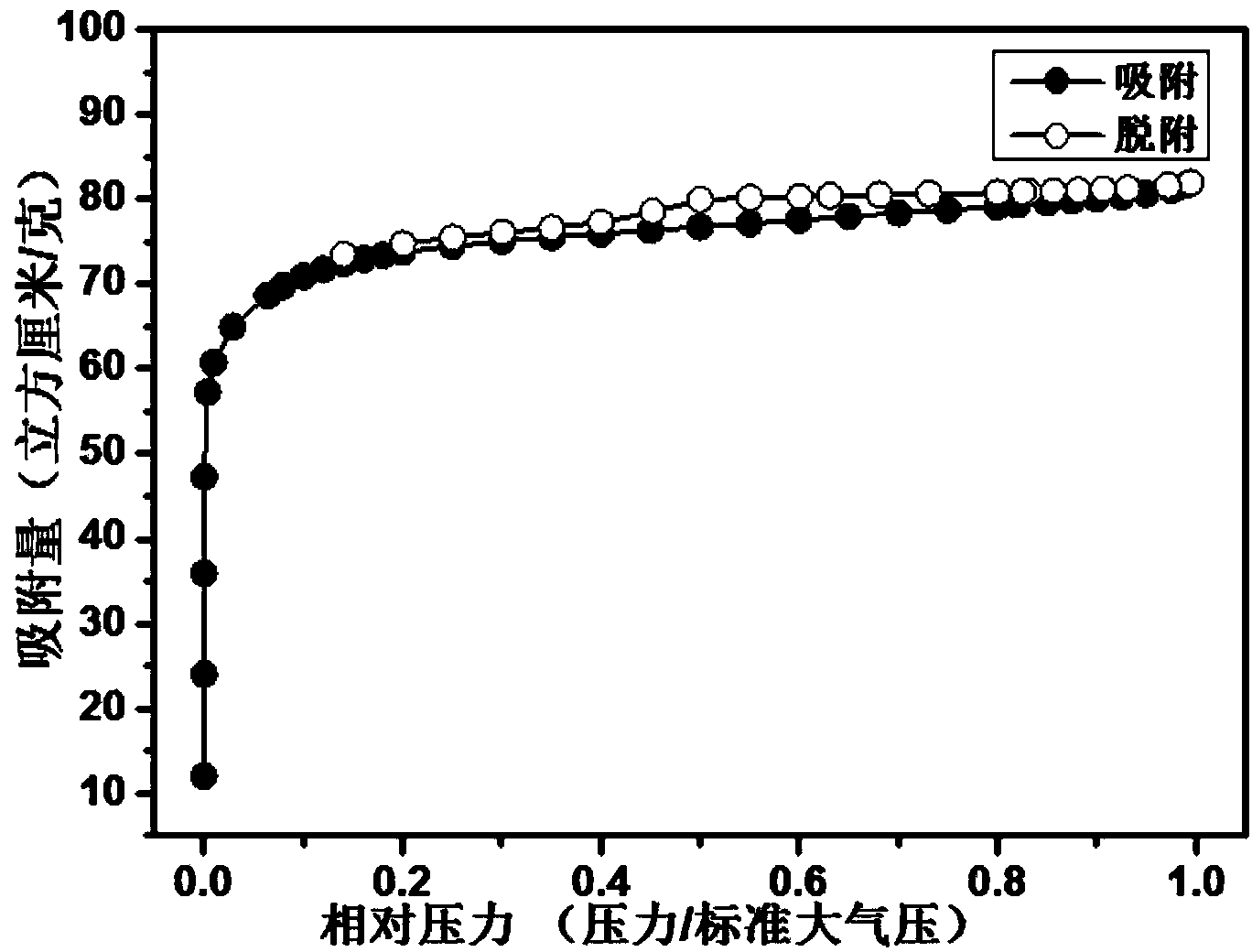

[0038] 2. Microporous SnO 2 Synthesis of C

[0039] The tin alginate precursor prepared in step 1 was placed in a muffle furnace at 500°C and annealed for 6 hours under the protection of an inert gas to transform tin alginate into SnO with a microporous s...

Embodiment 2

[0042] The preparation process of the carbon-coated transition metal oxide nanoparticle composite electrode material with microporous structure is as follows,

[0043] Specifically in two steps: 1. the synthesis of ferrous alginate:

[0044] Add 5 g of sodium alginate into 500 mL of deionized water, and heat and stir at 90° C. for 4 hours to completely dissolve it. Afterwards, 20 grams of ferrous chloride was added into 400 mL of deionized water, and stirred for 30 minutes to completely dissolve it. Then the two solutions are fully mixed for 2 hours to obtain ferrous alginate precipitate; after centrifugation and washing, dry at 100°C for 10 hours to obtain the ferrous alginate precursor;

[0045] 2. Microporous Fe 2 o 3 Synthesis of C

[0046] Place the ferrous alginate precursor prepared in step 1 in a muffle furnace at 800°C, and anneal for 4 hours under the protection of an inert gas to transform the ferrous alginate into Fe with a microporous structure. 2 o 3 C comp...

Embodiment 3

[0048] The preparation process of microporous carbon-coated transition metal oxide nanoparticles composite electrode material is as follows, specifically divided into two parts:

[0049] Step: 1. Synthesis of cobalt alginate:

[0050] Add 30 g of sodium alginate into 500 mL of deionized water, and heat and stir at 60° C. for 12 hours to completely dissolve it. Afterwards, 30 grams of cobalt sulfate was added into 400 mL of deionized water, and stirred for 20 minutes to completely dissolve it. Then, the two solutions are fully mixed for 1 hour to obtain cobalt alginate precipitate; after centrifugation and washing, dry at 80°C for 15 hours to obtain the cobalt alginate precursor;

[0051] 2. Microporous Co 3 o 4 Synthesis of C

[0052] The cobalt alginate precursor prepared in step 1 was placed in a muffle furnace at 500°C under the protection of an inert gas, and annealed for 6 hours to transform the cobalt alginate into a Co with a microporous structure. 3 o 4 Ccomposit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com