Magnetically-separatable ferriferrous oxide/silver chloride photocatalyst and preparation method thereof

A technology of ferroferric oxide and photocatalyst, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficult recycling, and achieve simplified preparation process, good photocatalytic activity and stability Sexuality, the effect that is conducive to large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

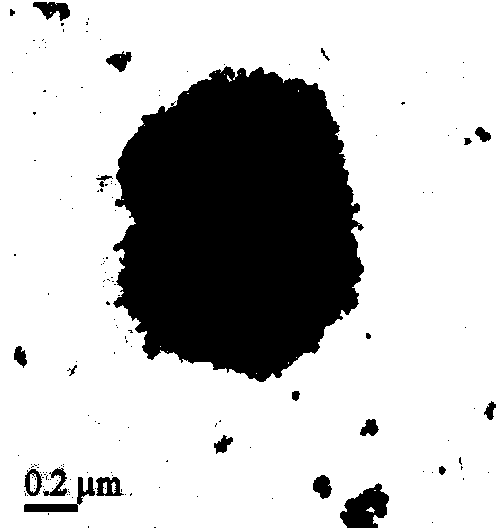

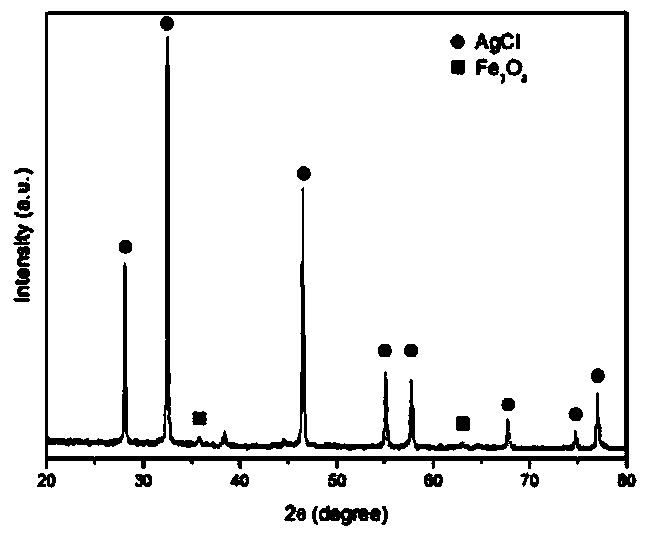

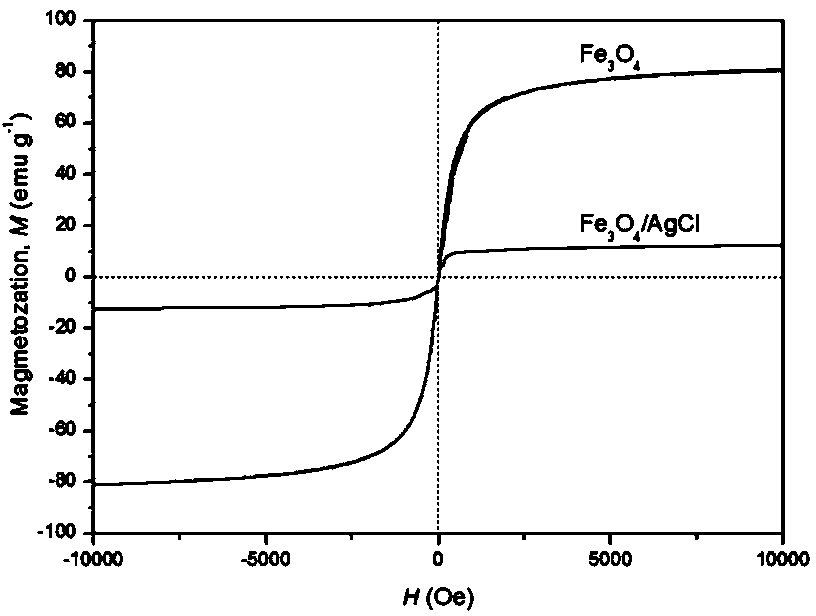

Image

Examples

Embodiment 1

[0032] A preparation method of ferric oxide / silver chloride photocatalyst with magnetic separation, comprising the following steps:

[0033] 1) Weigh 2.982g FeCl 2 4H 2 O was dissolved in 100mL deionized water, and 8.150g FeCl was weighed 3 ·6H 2 O was dissolved in 100mL deionized water, and 4.247g AgNO was weighed 3 Dissolve in 250mL deionized water to prepare a molar concentration of 0.3mol / L (48.66g / L) ferric chloride solution, 0.15mol / L (19.0g / L) ferrous chloride solution and 0.1mol / L ( 16.98g / L) silver nitrate solution, standby;

[0034] 2) Weigh 2mL of ferric chloride solution and 4mL of ferrous chloride solution and place them at a constant temperature of 70°C to mix and stir evenly; slowly add 0.1mol / L (4g / L) sodium hydroxide aqueous solution dropwise to adjust the pH to 6.5, And standing and aging at a constant temperature of 70°C for 1 hour to obtain a reaction mixture;

[0035] 3) Slowly add 120mL0.1mol / L (16.98g / L) silver nitrate solution dropwise to the reac...

Embodiment 2

[0038] A preparation method of ferric oxide / silver chloride photocatalyst with magnetic separation, comprising the following steps:

[0039] 1) Dissolve ferric chloride, ferrous chloride and silver nitrate in water respectively to prepare ferric chloride solution with a molar concentration of 0.3mol / L (48.66g / L), 0.15mol / L (19.0g / L) ferrous chloride solution and 0.1mol / L (16.98g / L) silver nitrate solution, standby;

[0040] 2) Weigh 2mL of ferric chloride solution and 4mL of ferrous chloride solution and place them at a constant temperature of 65°C to mix and stir evenly; slowly add 0.1mol / L (4g / L) sodium hydroxide aqueous solution dropwise to adjust the pH to 6.5, And standing and aging at a constant temperature of 65°C for 2 hours to obtain a reaction mixture;

[0041] 3) Slowly add 30mL0.1mol / L (16.98g / L) silver nitrate solution dropwise to the reaction mixture obtained in step 2), in the solution, Ag + : Cl - The content ratio is 1:1, fully stirred, and kept in the dark...

Embodiment 3

[0043] A preparation method of ferric oxide / silver chloride photocatalyst with magnetic separation, comprising the following steps:

[0044] 1) Ferric chloride, ferrous chloride, and silver nitrate were respectively dissolved in water to prepare a ferric chloride solution with a molar concentration of 0.3mol / L (48.66g / L), and a ferric chloride solution with a molar concentration of 0.15mol / L (19.0g / L). Ferrous chloride solution and 0.1mol / L (16.98g / L) silver nitrate solution, standby;

[0045] 2) Weigh 2mL of ferric chloride solution and 4mL of ferrous chloride solution and place them at a constant temperature of 75°C to mix and stir evenly; slowly add 0.1mol / L (4g / L) sodium hydroxide aqueous solution dropwise to adjust the pH to 7.0, And standing and aging at a constant temperature of 75°C for 2 hours to obtain a reaction mixture;

[0046] 3) Slowly add 60mL0.1mol / L (16.98g / L) silver nitrate solution dropwise to the reaction mixture obtained in step 2), in the solution, Ag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com