A light-enzyme composite catalytic functional microbial water purifier for cultured anaerobic sewage

A technology of functional microorganisms and water purifiers, which is applied in the direction of water pollutants, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve good compatibility, realize pollution control, and improve the effect of nitrogen and phosphorus removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

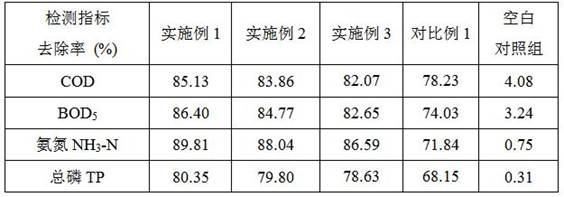

Examples

Embodiment 1

[0046] A light-enzyme composite catalytic functional microbial water purifier cultivated in aquaculture anaerobic sewage, the specific content is:

[0047] (1) Preparation of carbon ferrite supports with hydrophilic, magnetic and photocatalytic functions

[0048] 1) Put 50.00 g of fern leaf powder (with a particle size of 0.15 cm) and 25 g of ferric chloride into a 200 ml reactor liner, add 150 ml of deionized water, the reaction temperature is 180 ° C, and the reaction time is 18 hours. Carbon precursor-iron hydroxide composite material;

[0049] 2) The carbon precursor-iron hydroxide composite material prepared in step 1) was washed with water and absolute ethanol in sequence, and then dried at 60°C for 12 hours to obtain a carbon precursor-iron hydroxide composite material powder sample;

[0050] 3) The carbon precursor-iron hydroxide composite powder sample was calcined in a nitrogen atmosphere at 400°C for 2 hours to obtain a porous carbon-iron oxide material powder;

...

Embodiment 2

[0053] A light-enzyme composite catalytic functional microbial water purifier cultivated in aquaculture anaerobic sewage, the specific content is:

[0054] (1) Preparation of carbon ferrite supports with hydrophilic, magnetic and photocatalytic functions

[0055] 1) Put 50.00 g of fern leaf powder (0.15 cm in particle size) and 25 g of ferric chloride into a 200 ml reactor liner, add 150 ml of deionized water, the reaction temperature is 160 °C, and the reaction time is 12 hours. Carbon precursor-iron hydroxide composite material;

[0056] 2) Wash the carbon precursor-iron hydroxide composite material prepared in step 1) successively with water and absolute ethanol, and dry at 60°C for 12 hours to obtain the carbon precursor-iron hydroxide composite material powder;

[0057] 3) The carbon precursor-iron hydroxide composite powder sample was calcined in a nitrogen atmosphere at 500°C for 2 hours to obtain a porous carbon-iron oxide material powder;

[0058] (2) Add 100 g of p...

Embodiment 3

[0060] A light-enzyme composite catalytic functional microbial water purifier cultivated in aquaculture anaerobic sewage, the specific content is:

[0061] (1) Preparation of carbon ferrite supports with hydrophilic, magnetic and photocatalytic functions

[0062] 1) Put 50.00 g of fern leaf powder (0.15 cm in particle size) and 25 g of ferric chloride into a 200 ml reactor liner, add 150 ml of deionized water, the reaction temperature is 200 ° C, and the reaction time is 24 hours. Carbon precursor-iron hydroxide composite material;

[0063] 2) The carbon precursor-iron hydroxide composite material obtained in step 1) was washed with water and absolute ethanol in sequence, and then dried at 60°C for 12 hours to obtain a carbon precursor-iron hydroxide composite material powder sample;

[0064] 3) The carbon precursor-iron hydroxide composite powder sample was calcined in a nitrogen atmosphere at 450°C for 2 hours to obtain a porous carbon-iron oxide material powder;

[0065] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com