Comprehensive treatment system for roll paper tailings

A comprehensive processing and roll paper technology, which is applied in the direction of conveying bulk materials, separating solids from solids with airflow, solid separation, etc., can solve problems such as disorder, save processing costs, reduce labor intensity, and reduce labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

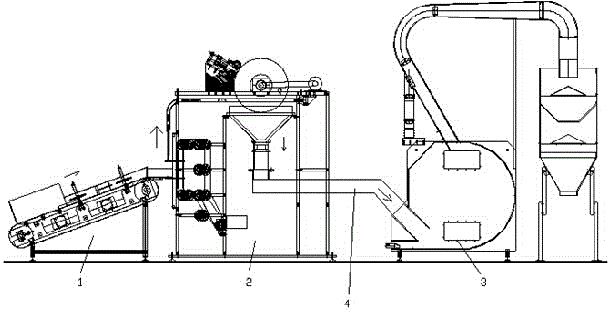

[0026] refer to Figure 1 to Figure 6 A comprehensive processing system for web tailings is shown, including a vacuum sorting and conveying unit 1, a conical array cutting unit 2 and an airflow centrifugal separation system 3;

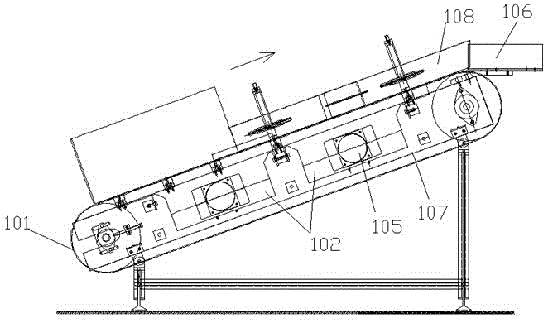

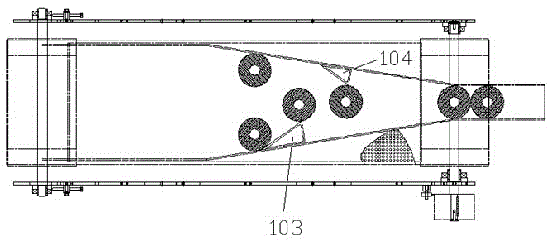

[0027] The vacuum sorting conveying unit 1 comprises a vacuum conveyor belt 101, a vacuum box 102, a left distributor 103, a right distributor 104, a vacuum flange interface 105, a vacuum pump and a lifting platform 106, and the inside of the vacuum conveyor belt 101 Baffles 107 are provided at the upper and lower positions, guide plates 108 are installed on the front and rear sides of the vacuum conveyor belt 101, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com