Method for efficiently spraying, evaporating and coring desulfurization wastewater in thermal power plant

A desulfurization wastewater, spray evaporation technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of limited distance of the flue at the tail of the boiler, reduced dust removal efficiency, low flue gas temperature, etc. problem, to achieve the effect of improving the atomization effect, reducing the evaporation, and improving the evaporation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

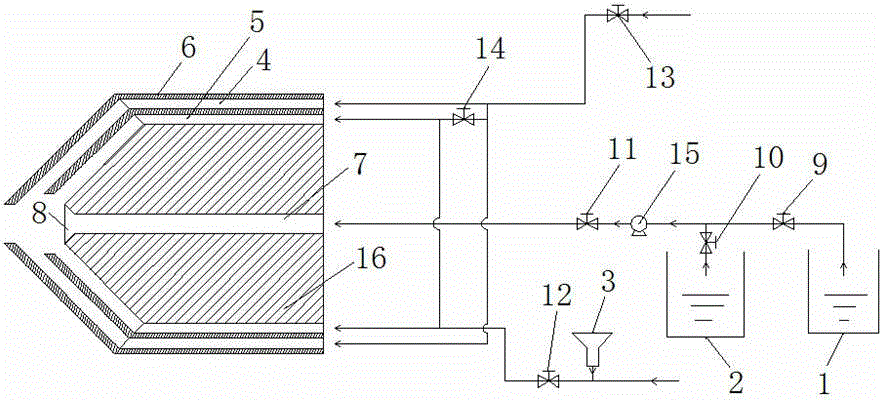

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] A method for efficient spray evaporation nucleation of thermal power plant desulfurization wastewater, in which a nozzle 16 is used, the structure of the nozzle is as follows figure 1 As shown, the middle part of the nozzle 16 is provided with a waste water passage 7 that runs through the nozzle 16, and an inner air duct 5 is respectively arranged in the nozzle 16 and above and below the waste water passage 7, and in the nozzle 16 and above and below the waste water passage 7 respectively An outside air duct 4 is set, and the outside air duct 4 is positioned outside the inside air duct 5. The outlet of the waste water channel 7 is a waste water spout 8, and one end of the inside air duct 5 and the outside air duct 4 all extends to the waste water spout 8.

[0030]The method is as follows: the waste water in the desulfurization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com