Halogen-free flame retardant glass fiber reinforced polyphenyl ether/polystyrene composition and preparation method thereof

A technology of polystyrene and polyphenylene ether, applied in the field of polymer alloy materials, can solve the problem of reducing the strength and rigidity of glass fiber reinforced polyphenylene ether and its alloy materials, changes in the melt viscosity of alloy materials, and large amounts of flame retardants added and other problems, to achieve the effect of good molding performance, smooth surface and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

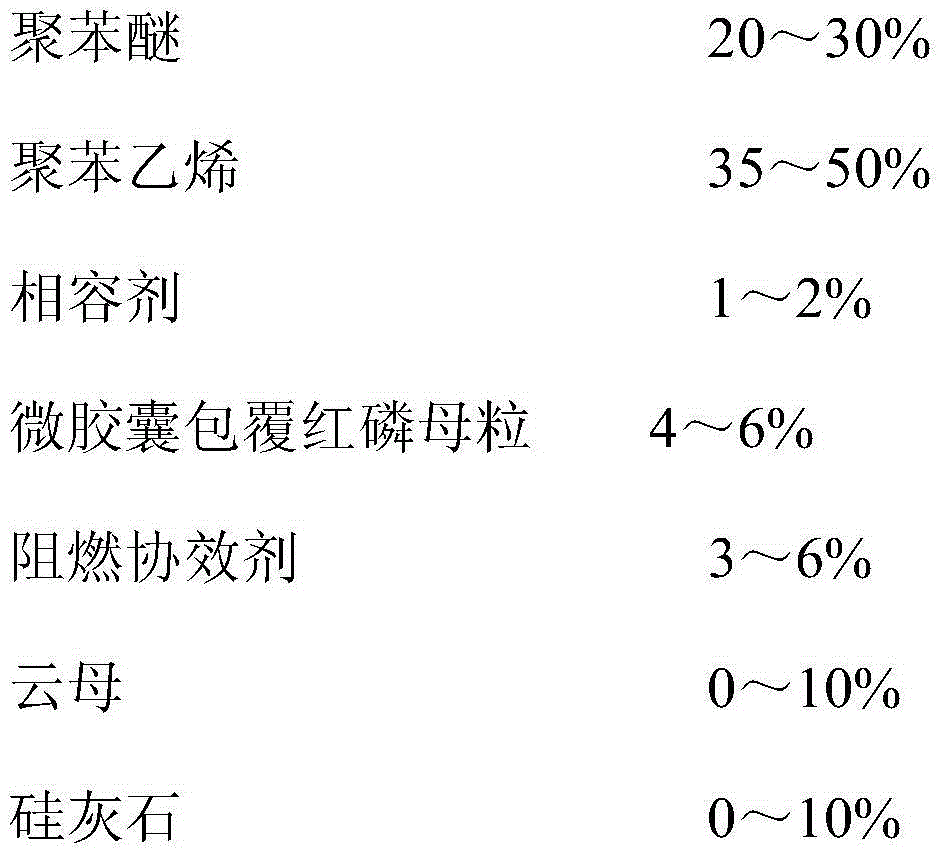

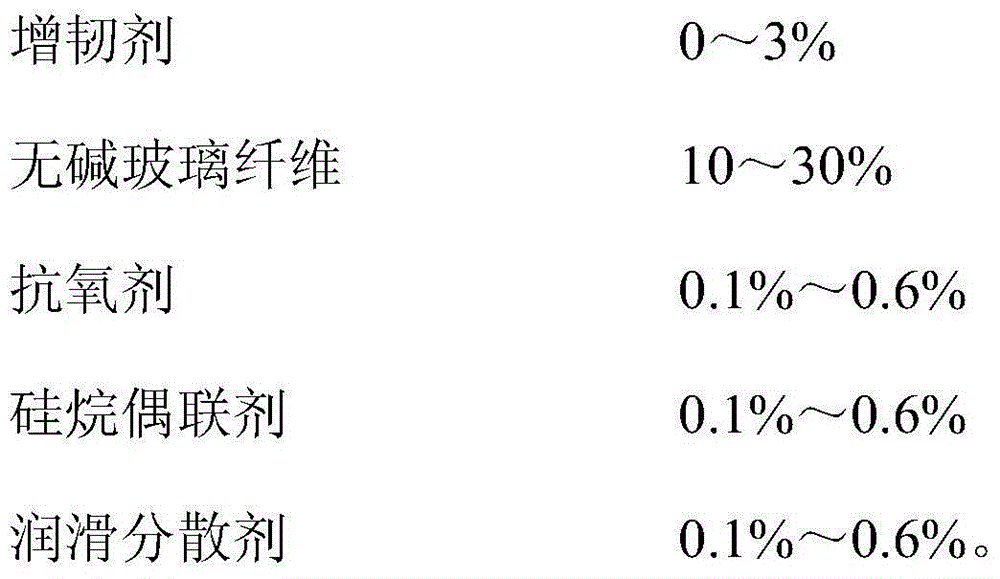

Method used

Image

Examples

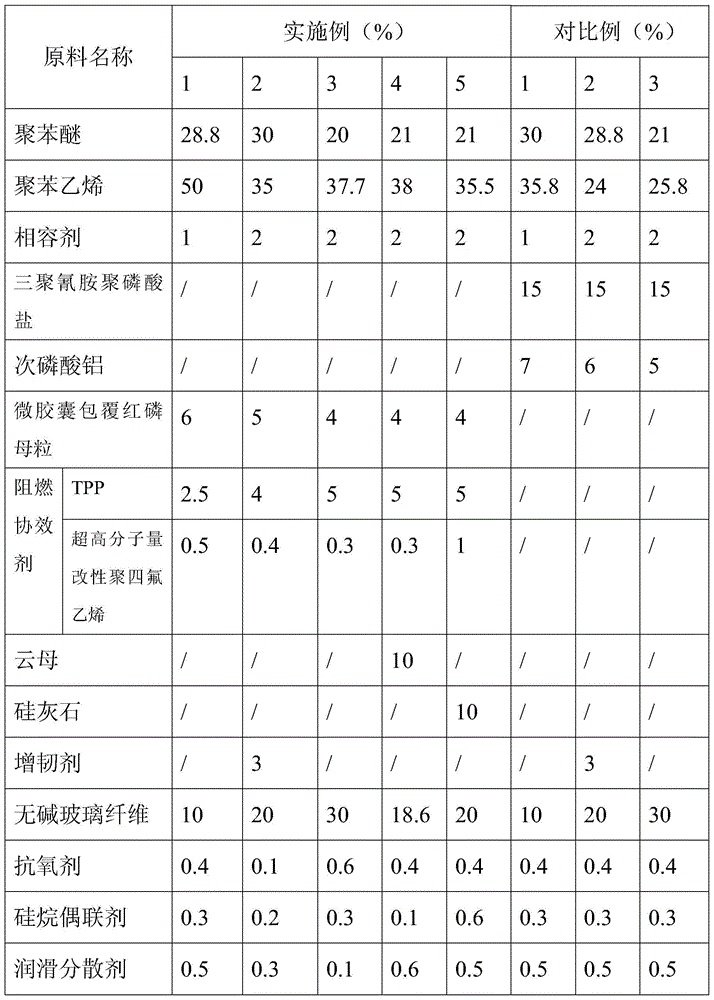

Embodiment 1-5

[0029] The preparation method of embodiment 1-5 is as follows:

[0030] a. Add other components except alkali-free glass fiber, silane coupling agent and flame retardant synergist into the high-speed mixer, add silane coupling agent and flame retardant synergist while stirring at low speed, and mix for 3 to 5 minutes;

[0031] b. The mixture obtained in step a is added to the twin-screw extruder from the first barrel feeding section of the twin-screw extruder, and the alkali-free glass fiber is added to the twin-screw extruder from the fourth barrel of the twin-screw extruder, and extruded grain;

[0032] Wherein the screw length-to-diameter ratio of the twin-screw extruder is 32-68, the rotational speed of the twin-screw extruder is 180-500 rpm, and the temperature is 215-255°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com