High-acid-value fuel composite catalytic esterification/deacidification method

A composite catalytic ester and composite catalyst technology, applied in the petroleum industry, refined hydrocarbon oil, etc., can solve the problems of harsh process and high esterification temperature, achieve the effects of less dosage, fast esterification reaction and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

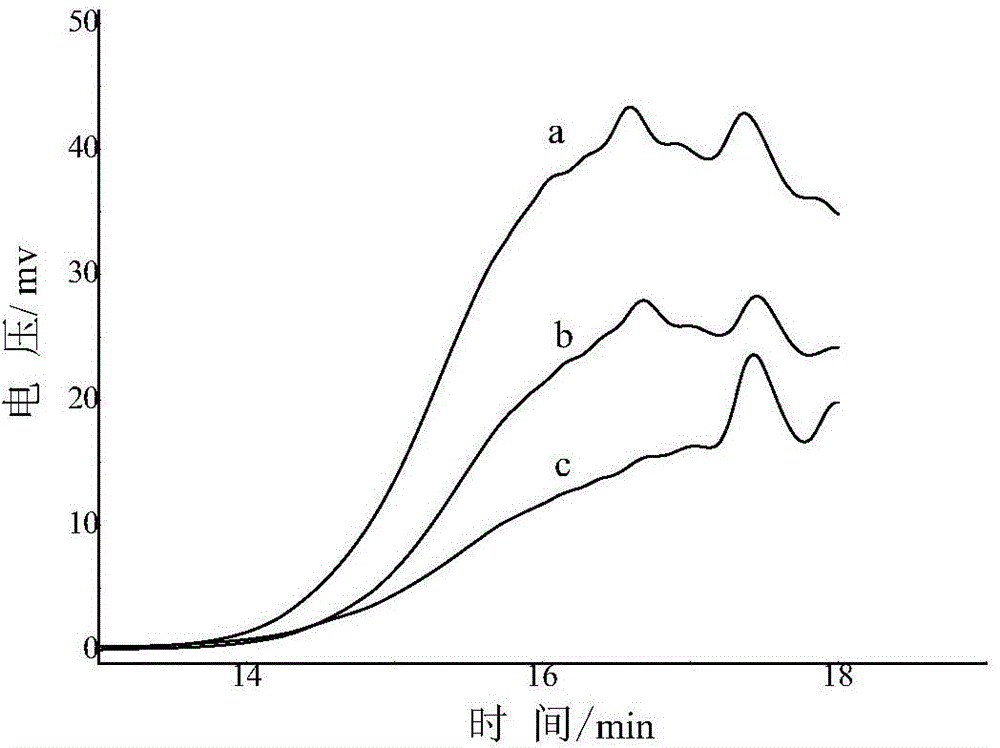

Image

Examples

Embodiment 1

[0026] The composite catalyst is composed of B acid: sulfamic acid and L acid: aluminum chloride, and its weight ratio is 6:4, and the two are compounded. The specific process of applying the composite catalyst with this ratio to the composite catalytic esterification and deacidification of high acid value fuel oil is as follows: take 120 g of fuel oil (acid value: 15.7 mgKOH) into the esterification reactor, and add 85 g of n-butanol to it , adding the composite catalyst, the amount of composite catalyst added is 0.5% by weight of fuel oil, the reaction temperature is controlled at 150 °C, the reaction is stirred for 2 h, the acid value is measured by sampling, and the deacidification rate of fuel oil is calculated to be 85.3%.

[0027]

Embodiment 2

[0029] The composite catalyst is composed of B acid: p-toluenesulfonic acid and L acid: ferric chloride, and the weight ratio is 8:2, and the two are compounded. The specific process of applying the composite catalyst with this ratio to the composite catalytic esterification and deacidification of high acid value fuel oil is as follows: Take 180 g of fuel oil (acid value: 13.9 mgKOH) into the esterification reactor, add 65 g of glycerin to it, add Composite catalyst, the amount of composite catalyst added is 0.8% of the weight of fuel oil, the reaction temperature is controlled at 150°C, the reaction is stirred for 4 hours, the acid value is measured by sampling, and the deacidification rate of fuel oil is calculated to be 87.7%.

[0030]

Embodiment 3

[0032] The composite catalyst is composed of B acid: sulfuric acid and L acid: titanium tetrachloride, the weight ratio is 5:5, and the two are compounded. The specific process of applying the composite catalyst with this ratio to the compound catalytic esterification deacidification of high acid value fuel oil is as follows: take 240 g fuel oil (acid value: 18.3 mgKOH) into the esterification reactor, add 96 g 1, 3-Butanediol was added to the composite catalyst. The amount of the composite catalyst added was 1.0% of the mass of the fuel oil. The reaction temperature was controlled at 150°C, and the reaction was stirred for 3 hours. The acid value was measured by sampling, and the deacidification rate of the fuel oil was calculated to be 94.7%.

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com