Method for preparing gram-level high-purity natural thiosulfinate

A thiosulfinate, high-purity technology, applied in the direction of fermentation, etc., can solve the problems of tediousness, reduce production efficiency, increase production cost, etc., and achieve the effect of high reaction yield, simple operation and rapid reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

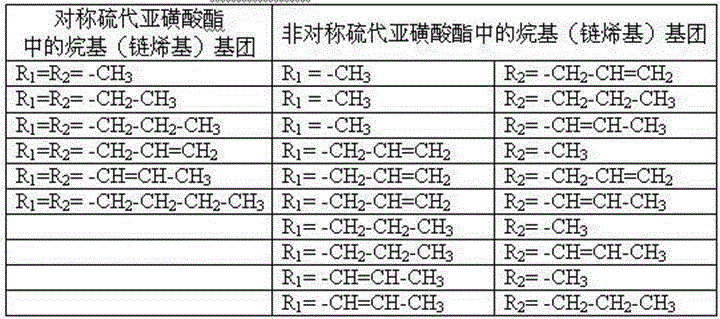

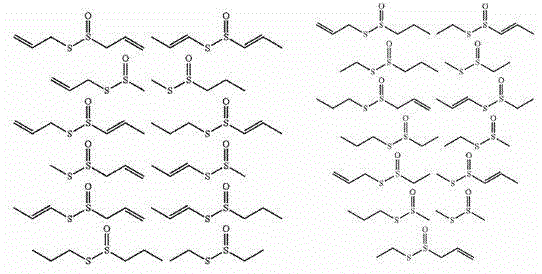

Embodiment 1

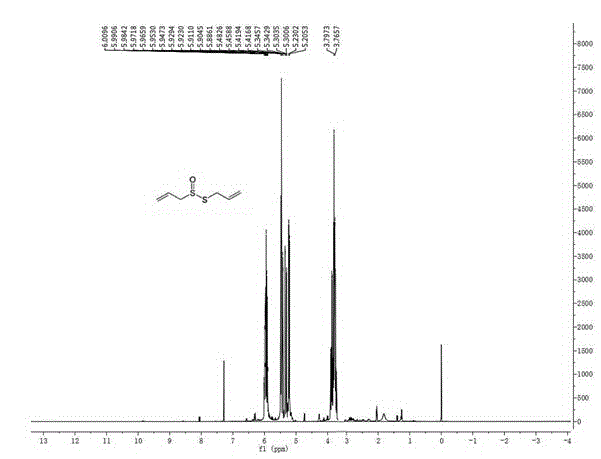

[0059] Example 1: Preparation of Diallyl Thiosulfinate (Allicin)

[0060] (1) Weigh 100g of peeled garlic bulbs, mix it with 20mL of deionized water at room temperature, crush the garlic tissue into a homogenate with a mechanical mixer or crusher at 0°C, and beat for 5 minutes to make a tissue homogenate.

[0061] (2) Incubate the garlic tissue homogenate obtained in step (1) at room temperature for 1 hour, filter it with roving cloth, and take the filtrate. At room temperature, the filtrate was washed twice with an equal amount of dichloromethane for 20 min each time to ensure complete extraction. The washed filtrate has sufficient enzymatic activity to catalyze the conversion of exogenous ACSO to thiosulfinate. The washing process can adopt centrifugation or ionization accelerated phase separation process.

[0062] (3) Dissolve 4 g of exogenous allyl cysteine sulfoxide ((±) 2-PeCSO) in 40 mL of deionized water to prepare an ACSO solution. Add the 2-PeCSO solution into t...

Embodiment 2

[0065] Embodiment 2: Preparation of diethyl thiosulfinate

[0066] (1) Weigh 100 g of peeled garlic bulbs, mix it with 90 mL of deionized water at room temperature, and crush the garlic tissue into a homogenate with a mechanical mixer or crusher at 4°C, and beat for 5 minutes to make a tissue homogenate.

[0067] (2) Incubate the garlic tissue homogenate obtained in step (1) at room temperature for 1 hour, filter it with roving cloth, and take the filtrate. At room temperature, wash the filtrate twice with 100 mL of dichloromethane for 15 min each time to ensure complete extraction. The washed filtrate has sufficient enzymatic activity to catalyze the conversion of exogenous ACSO to thiosulfinate. The washing process can adopt centrifugation or ionization accelerated phase separation process.

[0068] (3) Dissolve 3.6 g of exogenous S-ethyl-L-cysteine sulfoxide ((±) ECSO) in 30 mL of deionized water to prepare an ECSO solution. Add the ECSO solution to the aqueous extract...

Embodiment 3

[0071] Example 3: Preparation of Dipropylthiosulfinate (Allicin)

[0072] (1) Weigh 100g of peeled onion bulbs, mix it with 70mL of deionized water at room temperature, crush the garlic tissue into a homogenate with a mechanical mixer or crusher at 0°C, and beat for 10 minutes to make a tissue homogenate.

[0073] (2) Incubate the onion tissue homogenate obtained in step (1) at room temperature for 1 hour, filter it with roving cloth, and take the filtrate. At room temperature, wash the filtrate twice with 100 mL of dichloromethane for 20 min each time to ensure complete extraction. The washed filtrate has sufficient enzymatic activity to catalyze the conversion of exogenous ACSO to thiosulfinate. The washing process can adopt centrifugation or ionization accelerated phase separation process.

[0074] (3) Dissolve 2 g of exogenous S-propyl-L-cysteine sulfoxide ((±) PCSO) in 20 mL of deionized water to make a PCSO solution. The PCSO solution was added to the aqueous extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com