Solid fermentation ginseng flower and preparation method thereof

A solid fermentation, ginseng flower technology, applied in biochemical equipment and methods, fermentation, microbial-based methods, etc., can solve rare and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 preparation culture medium

[0033] C-Y medium: peptone 10g, yeast powder 5g, glucose 20g, ammonium acetate 2g, trisodium citrate 25g, magnesium sulfate 0.362g, manganese sulfate 0.2g, ferrous sulfate 0.03g, potassium dihydrogen phosphate 6g, polyoxyethylene dehydration Sorbitan monooleate 1mL, dissolved in 1L water, adjust pH 5.85.

[0034] C-Y-1 medium: peptone 10g, yeast powder 5g, ammonium acetate 2g, trisodium citrate 25g, magnesium sulfate 0.362g, manganese sulfate 0.2g, ferrous sulfate 0.03g, potassium dihydrogen phosphate 6g, polyoxyethylene dehydrated sorrel Alcohol monooleate 1mL, dissolved in 1L water, adjust pH 5.85.

[0035] C-Y-2 medium: glucose 20g, ammonium acetate 2g, trisodium citrate 25g, magnesium sulfate 0.362g, manganese sulfate 0.2g, ferrous sulfate 0.03g, potassium dihydrogen phosphate 6g, polyoxyethylene sorbitan monooleic acid Dissolve 1 mL of ester in 1 L of water and adjust the pH to 6.05.

[0036] The above-mentioned medium...

Embodiment 2

[0038] Example 2 Identification of plantarum lactobacillus producing β-glucosidase

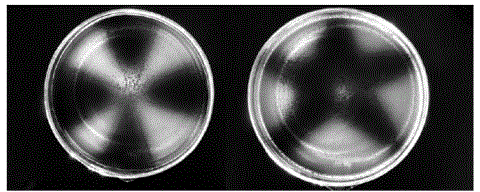

[0039] Perform aseptic operation in an ultra-clean workbench, pour the prepared aescin-R2A solid medium onto the plate, and after the medium is cooled and solidified, pick Lactobacillus plantarum (Lactobacillus plantarum) with an inoculation loop and spread it on the plate One side and the other side as blank treatment, move the plate from the ultra-clean workbench into a biochemical incubator, set the culture temperature at 37°C, and culture it statically for 48 hours, take out the plate and observe the color of the medium-coated side and the blank treatment change, resulting in the coated side turning black (see figure 1 ).

Embodiment 3

[0040] The selection of embodiment 3 seed culture medium

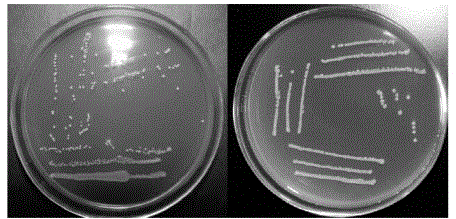

[0041] Pour the prepared medium onto the plate, and after the medium is cooled and solidified, pick Lactobacillus plantarum with an inoculation loop, inoculate the strains in the medium by 4-section line inoculation, move them into the biochemical incubator, and set The culture temperature was 37°C, and after 48 hours of static culture, the growth characteristics of the strain were observed. After Lactobacillus plantarum was inoculated into the C-Y medium, the growth of the colony was significantly better than that of the SL medium, such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com